Automatic splitting machine

A technology of automatic slitting machine and rewinding mechanism, which is applied in the direction of winding strips, sending objects, thin material processing, etc. Small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

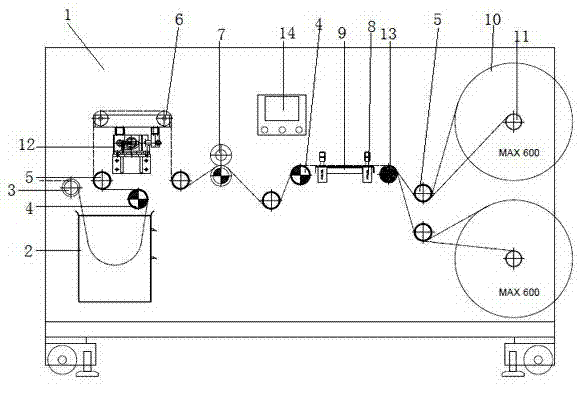

[0014] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0015] see figure 1 , the automatic slitting machine of the present invention, preferably wall-mounted, reduces the floor space, and specifically includes: a main body 1, a PLC controller, and a set that is fixedly connected to the main body 1 and is controlled by the PLC controller and arranged in sequence according to the feeding direction. The reel 3, the material storage box 2, the flattening mechanism, the cutting mechanism, the material receiving mechanism and the winding mechanism also include a plurality of transmission rollers 4 and tension shafts 5. Wherein, the flattening mechanism includes: a pair of flattening shafts 6 located on the same horizontal plane; The material-receiving plane 9 on the top surface of the block 8, the rewinding mechanism includes two rewinding shafts 10 with the same structure, the rewinding shaft 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com