Conical scintillation crystal module and processing method thereof

A technology of scintillation crystals and processing methods, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as lack of data collection, achieve accurate cutting, improve imaging quality, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: A conical scintillation crystal module

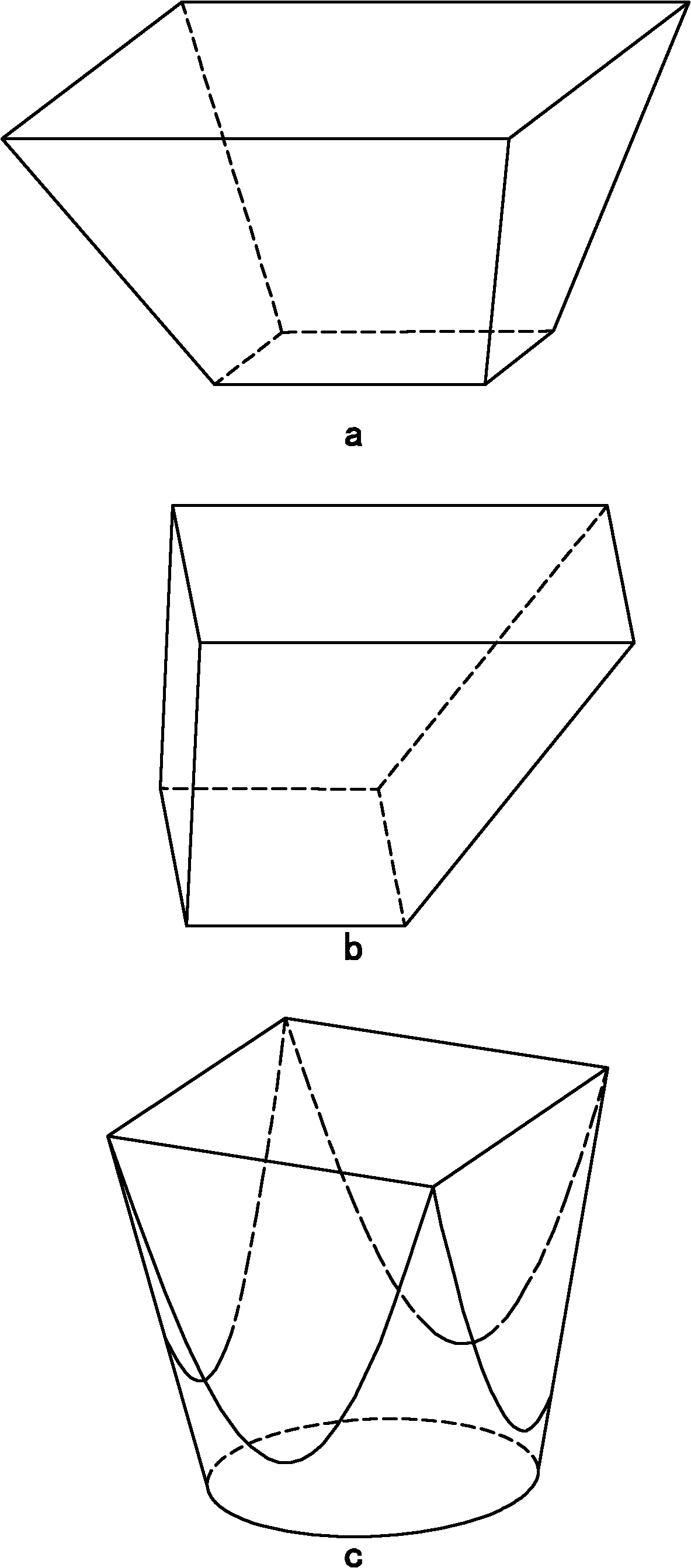

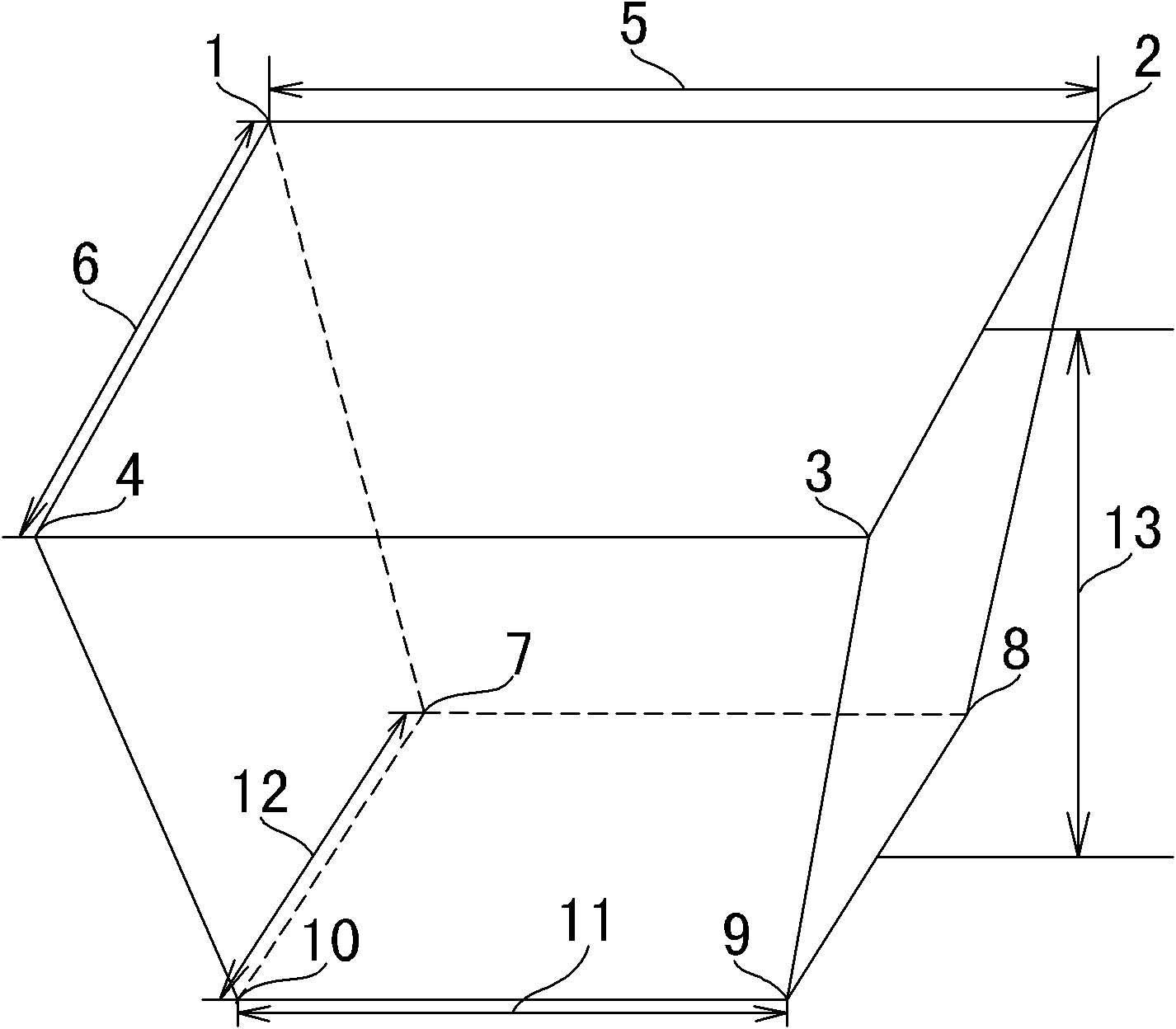

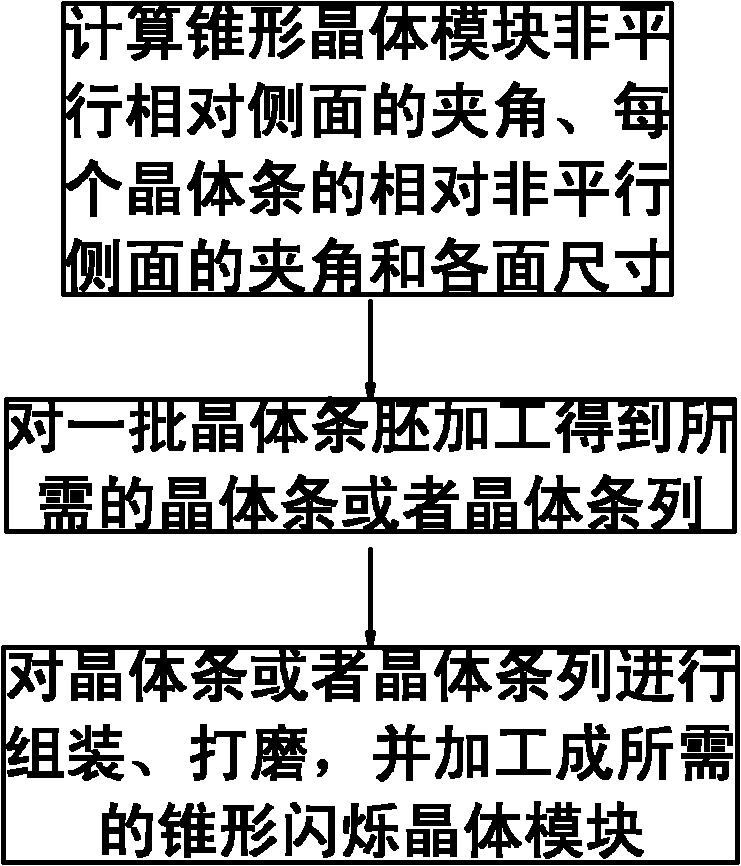

[0032] as attached figure 1 As shown in (a), a conical scintillation crystal module, the three-dimensional appearance of the conical scintillation crystal module is a conical frustum, the top surface and the bottom surface of the conical frustum are parallel to each other, both the top surface and the bottom surface are rectangular, and the top surface The area is greater than the area of the bottom surface. Such as figure 2 As shown, the top length of the cone-shaped scintillation crystal module is defined as Top_length5, the width is Top_width6, the bottom surface length is Bottom_length11, the width is Bottom_width12, the distance between the top surface and the bottom surface is height13, and Top_length, Top_width, Bottom_length, Bottom_width, and height are all greater than zero. as attached Figure 4 As shown, the tapered scintillation crystal module is composed of an array of 4×3 crystal strips, where 4...

Embodiment 2

[0033] Embodiment 2: A conical scintillation crystal module

[0034] as attached figure 1 As shown in (b), a conical scintillation crystal module, the three-dimensional appearance of the conical scintillation crystal module is a conical frustum, the top surface and the bottom surface of the conical frustum are parallel to each other, both the top surface and the bottom surface are rectangular, and the top surface The area is greater than the area of the bottom surface. Such as figure 2 As shown, the top length of the cone-shaped scintillation crystal module is defined as Top_length5, the width is Top_width6, the bottom surface length is Bottom_length11, the width is Bottom_width12, the distance between the top surface and the bottom surface is height13, and Top_length, Top_width, Bottom_length, Bottom_width, and height are all greater than zero. as attached Figure 5 As shown, the tapered scintillation crystal module is composed of an array of 12×6 crystal strips, wherei...

Embodiment 3

[0035] Embodiment 3: A conical scintillation crystal module

[0036] as attached figure 1 (a), (b) and appended Figure 6 As shown, a conical scintillation crystal module, the three-dimensional appearance of the conical scintillation crystal module is a conical frustum, the top surface and the bottom surface of the conical frustum are parallel to each other, both the top surface and the bottom surface are rectangular, and the area of the top surface is larger than that of the bottom surface area. Such as figure 2 As shown, the four vertices on the top surface of the cone-shaped scintillation crystal module are defined clockwise as Top_A1, Top_B2, Top_C3, and Top_D4, and the four vertices corresponding to the bottom surface are Bottom_A7, Bottom_B8, Bottom_C9, and Bottom_D10. Among them, the vertices Top_X and Bottom_X form a cone-shaped scintillation A side edge of the crystal module, X=A, B, C, D, the direction of the straight line where the vertices Top_A and Top_B are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com