Method of manufacturing panel switch and panel switch

A panel switch and manufacturing method technology, applied to the panel switch manufacturing, panel switch manufacturing method and the field of panel switches, can solve the problems of waste of mold correction costs and production time, increased man-hours, decreased operability, etc., to achieve finished products The effect of increasing the efficiency, reducing the area and eliminating the position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

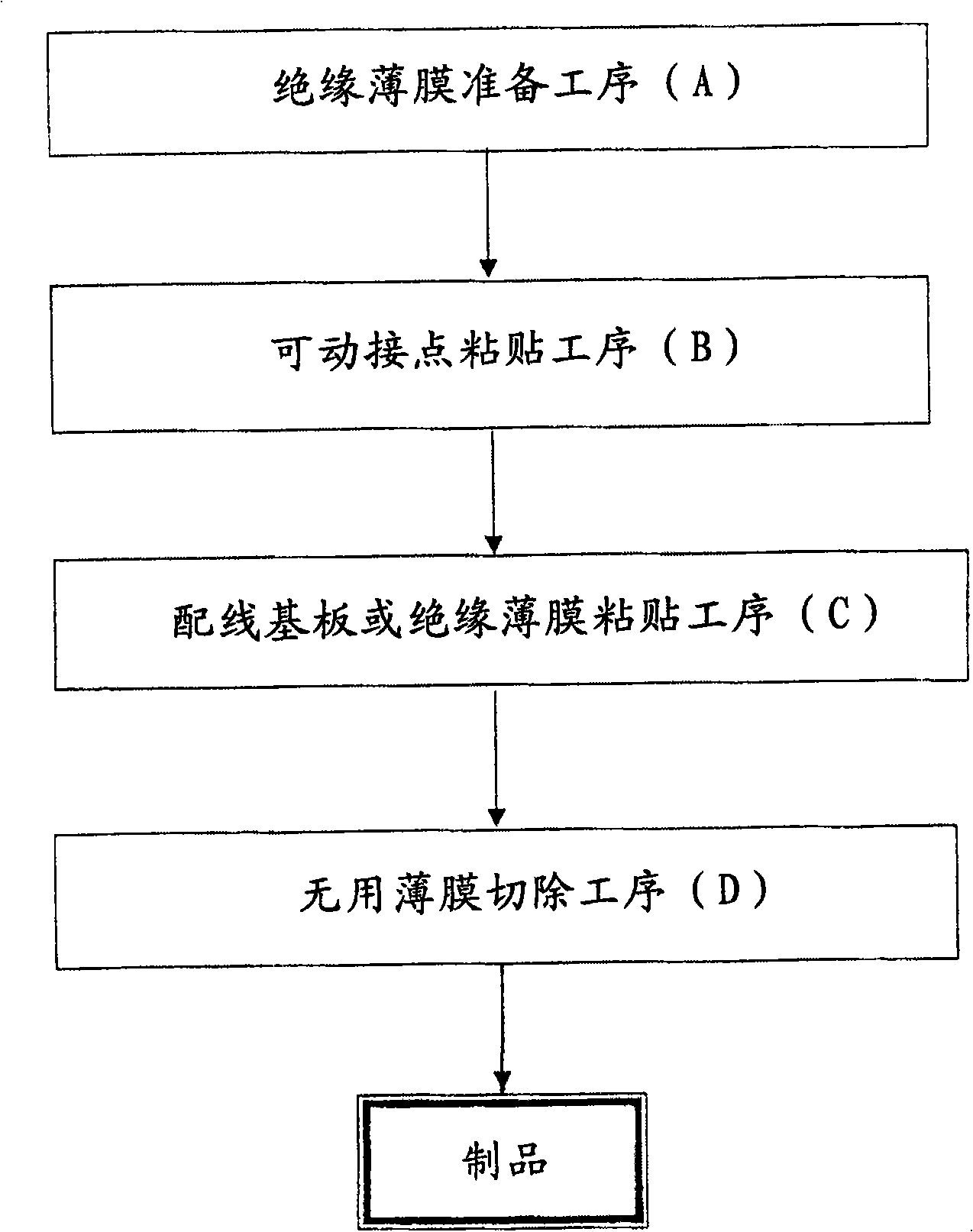

[0073] Hereinafter, the structure of the panel switch manufactured by the manufacturing method of this invention is given and demonstrated with preferable Example together with the manufacturing method. This embodiment is suitable for a panel switch shipped as a product in a state where a plurality of insulating film sheets are mounted on a wiring board or a spacer as a base member.

no. 1 approach

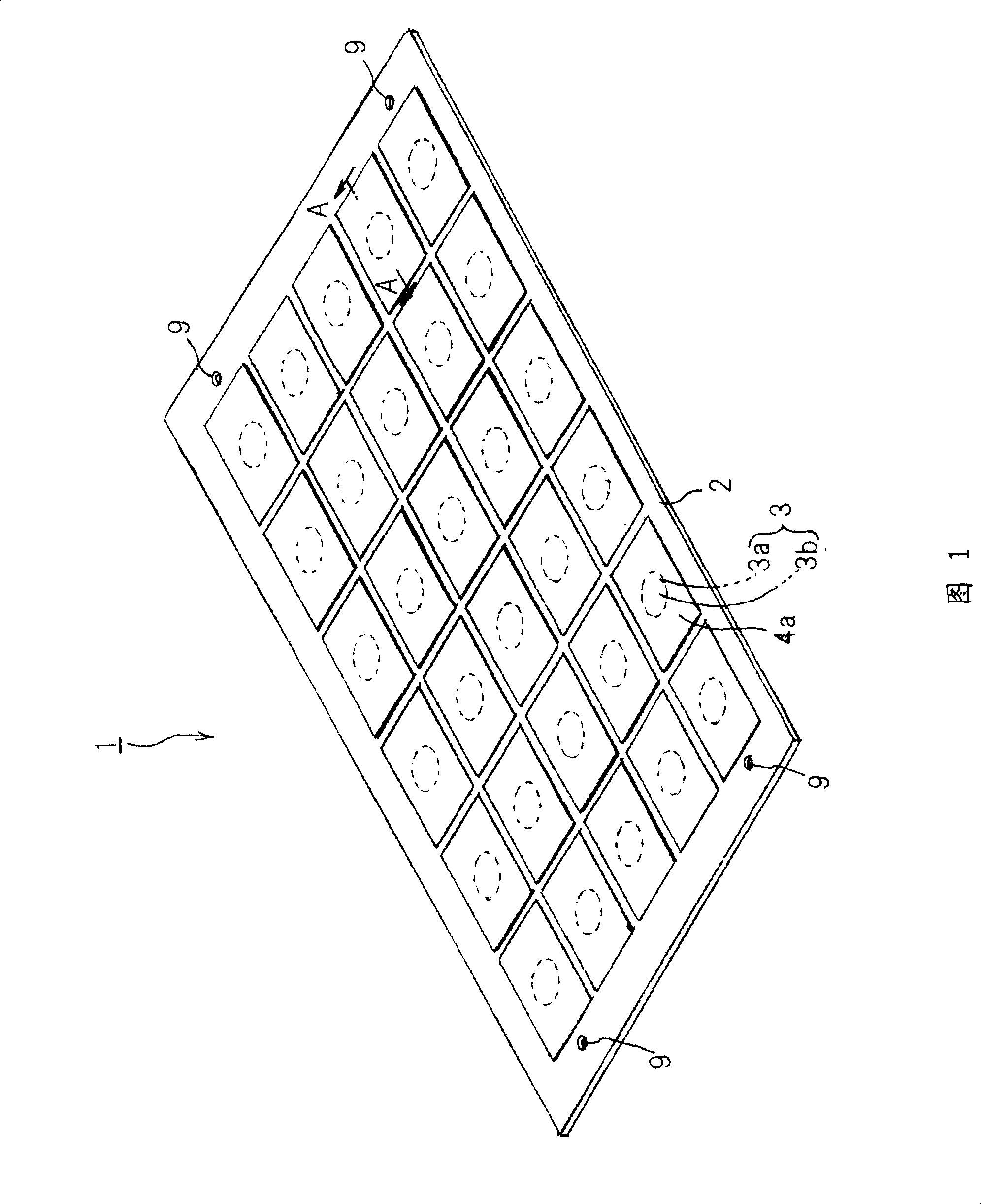

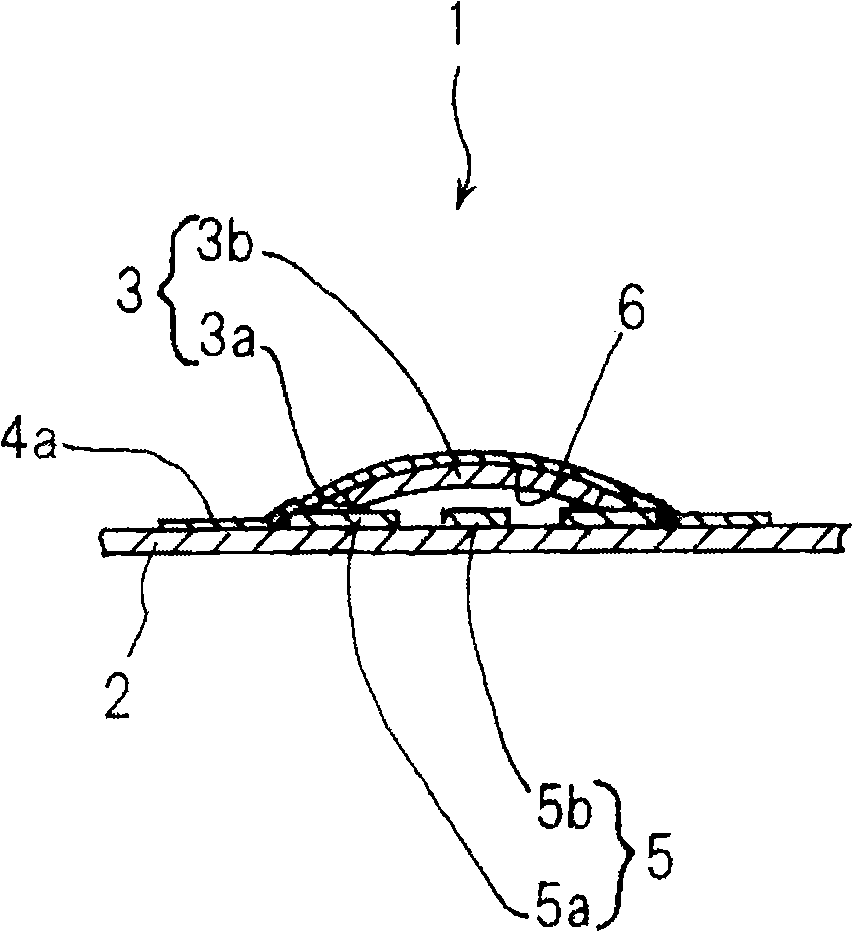

[0075] 1 is a perspective view of a panel switch manufactured by the manufacturing method of the first embodiment, figure 2 It is an enlarged cross-sectional view taken along line A-A of FIG. 1 . Figure 1 and figure 2 The panel switch 1 shown uses a wiring board 2 as a base member.

[0076] In Figure 1 and figure 2 Among them, the panel switch 1 includes: a wiring board (base member) 2 having a plurality of fixed contacts 5; a plurality of, for example, 30 movable contacts 3, 3... disposed on the wiring board 2; and A plurality of insulating film sheets 4a, 4a... are mounted on the wiring board 2 to cover the movable contacts 3, 3..., respectively.

[0077] Such as figure 2 As shown, on the above-mentioned wiring board 2, fixed contacts 5 are respectively provided by printing or the like on the surface of the sheet-shaped insulating film and at a plurality of places where the switch section is formed. Each fixed contact 5 includes: an outer electrode 5a formed in a su...

no. 2 approach

[0100] Figure 9 It is a manufacturing process drawing showing the second embodiment of the present invention, Fig. 10 and Figure 11 It is a structural diagram and a sectional view of the panel switch 21 manufactured by the manufacturing method of 2nd Embodiment. In the manufacturing method of the second embodiment, the movable contact superposition step (E) is added to the manufacturing steps (A) to (D) of the first embodiment, and the other steps are substantially the same as the manufacturing steps of the first embodiment.

[0101] Moreover, the panel switch 21 manufactured through the manufacturing process of the second embodiment is also the same as the first embodiment. The movable contacts 3, 3... are mounted on the adhesive layer 6 of the above-mentioned insulating film 4. The insulating films 4 of the movable contacts 3, 3... are different in that they are laminated in two layers, and the other structures are the same. Therefore, the same symbols are assigned to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com