Film cutting machine

A cutting machine and film technology, applied in thin material processing, metal processing, winding strips, etc., can solve problems such as inaccurate measurement, uneven stacking, and waste of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

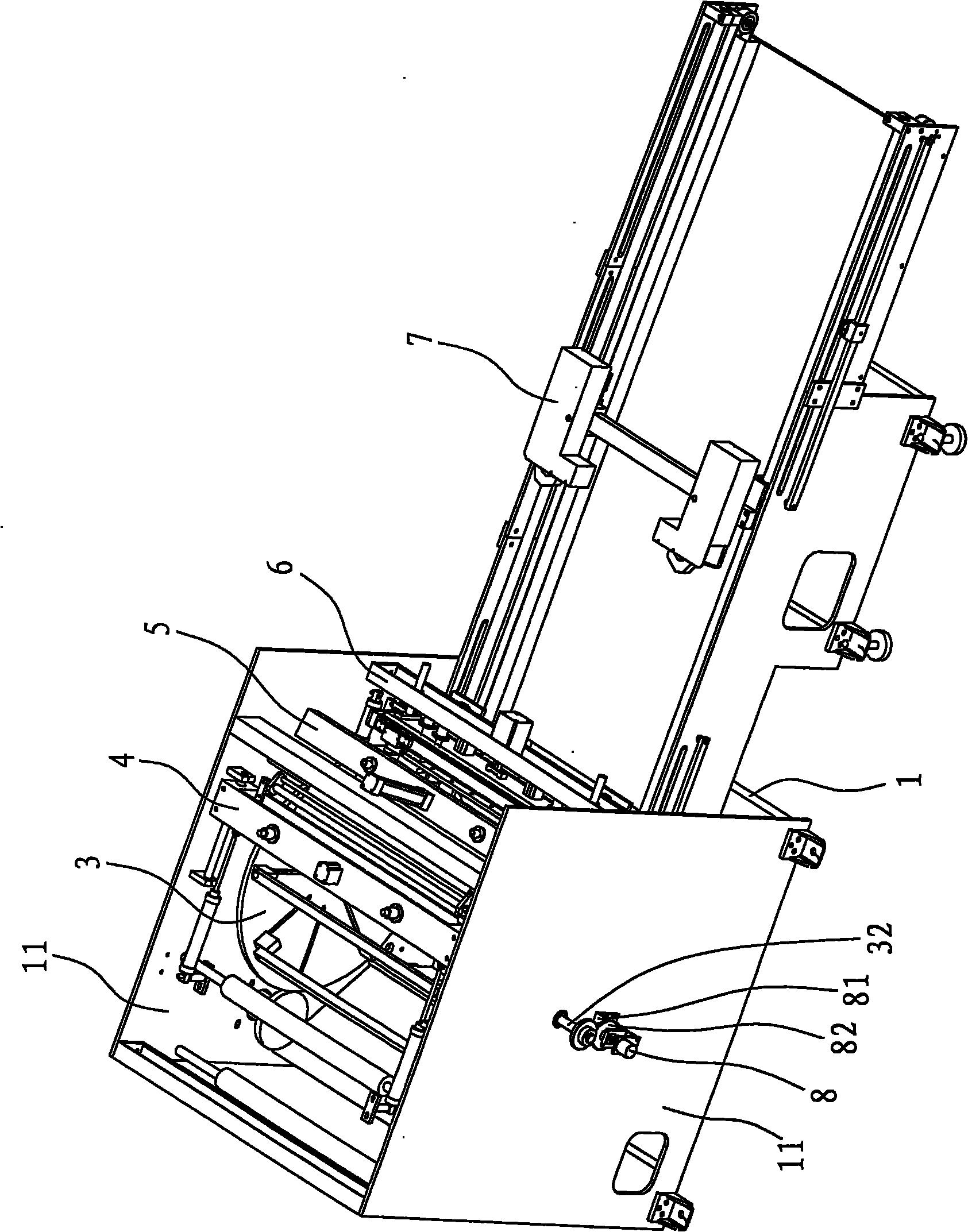

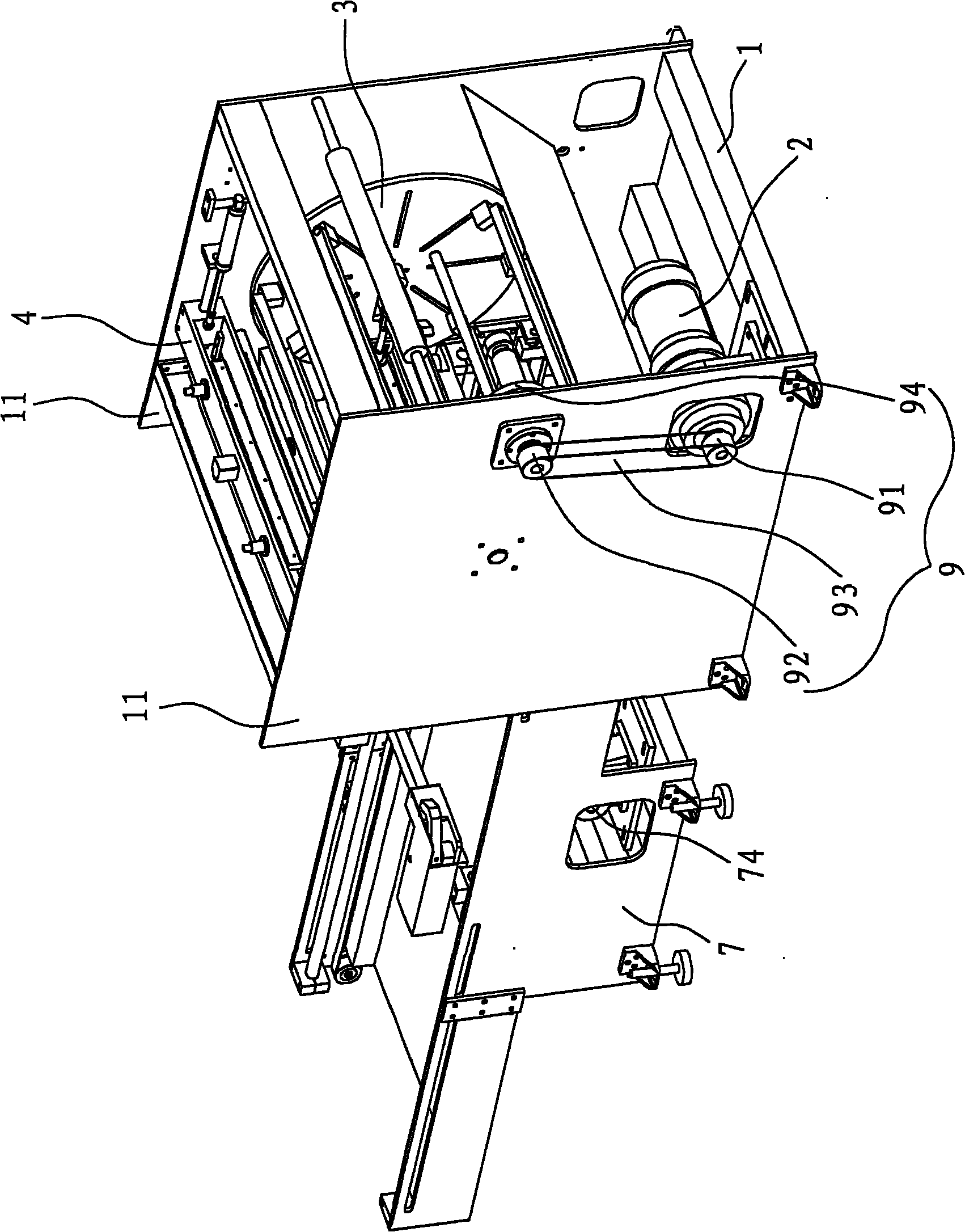

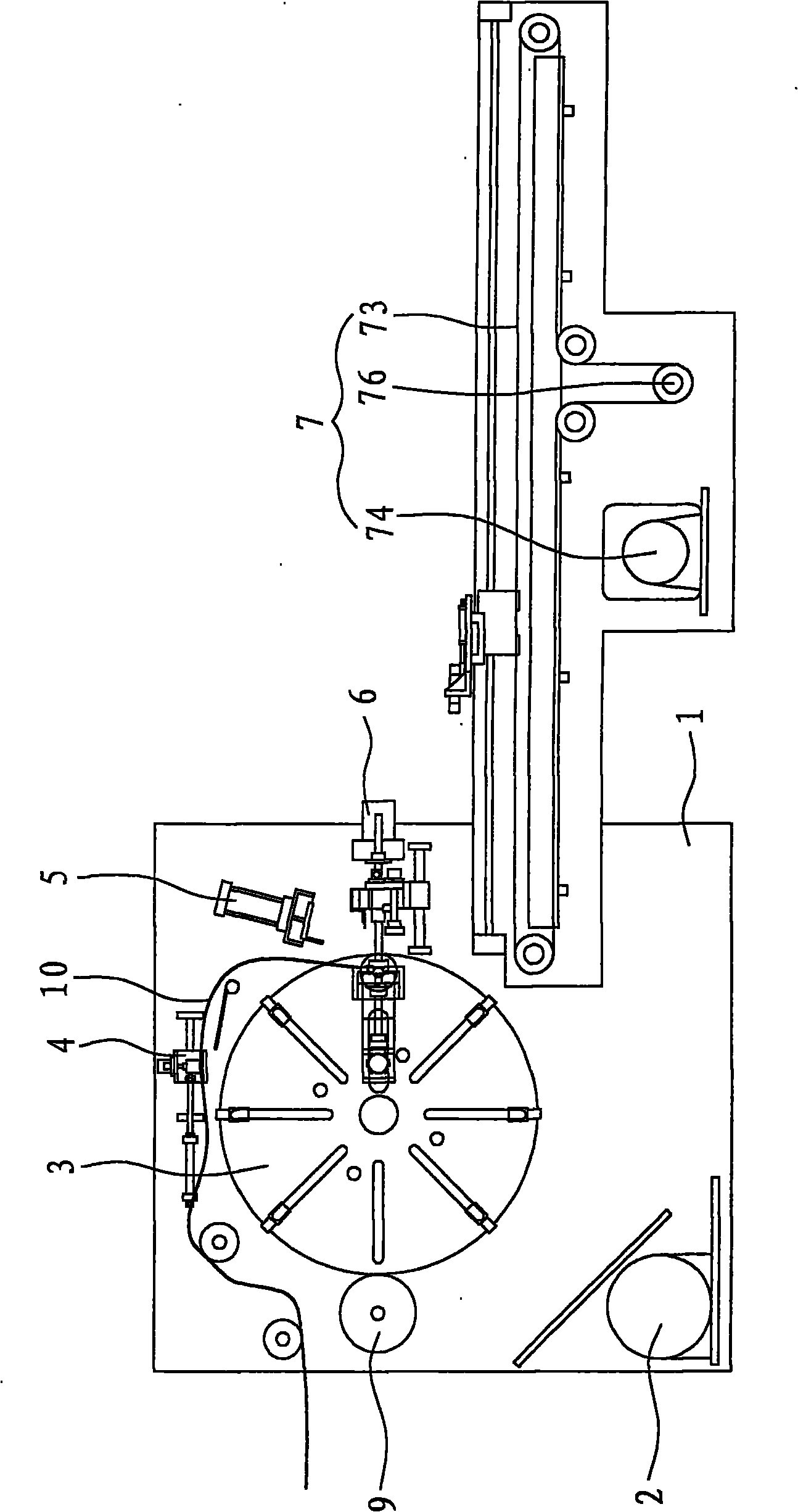

[0024] Such as figure 1 one image 3 Shown, the present invention is a kind of film cutting machine, and it mainly consists of frame 1, motor 2, winding device 3, feeding device 4, guiding device 5, slicing device 6, unloading device 7, detection device 8, transmission mechanism 9 composition.

[0025] The transmission mechanism 9 includes a master synchronous pulley 91 , a slave synchronous pulley 92 , a synchronous belt 93 and a synchronous gear 94 . Described motor 2 is installed on the bottom of frame 1, and motor 2 drives main synchronous pulley 91, drives slave synchronous pulley 92 by synchronous belt 93, from synchronous pulley 92 and synchronous gear 94 coaxial, synchronous gear 94 and receiving The turntable 311 (shown in FIG. 5 ) in the roll device 3 is engaged, thereby driving the turntable 311 to move. The rewinding device 3 is rotatably mounted on the side plate 11 of the frame 1, the feeding device 4 is mounted on the frame 1 and is located above the rewindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com