Optical fiber Fabry-Perot sensor and manufacture method therefore

A technology of Fap sensor and manufacturing method, which is applied in the direction of converting sensor output, using optical devices to transmit sensing components, instruments, etc., which can solve the problems of small contrast of sensor reflection stripes, low temperature resistance, and difficulty in large-scale manufacturing, etc., to achieve Save the manual packaging process, mechanical stability and high temperature resistance, and achieve the effect of large-scale manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Manufacture fiber optic Fabulous temperature, strain sensor

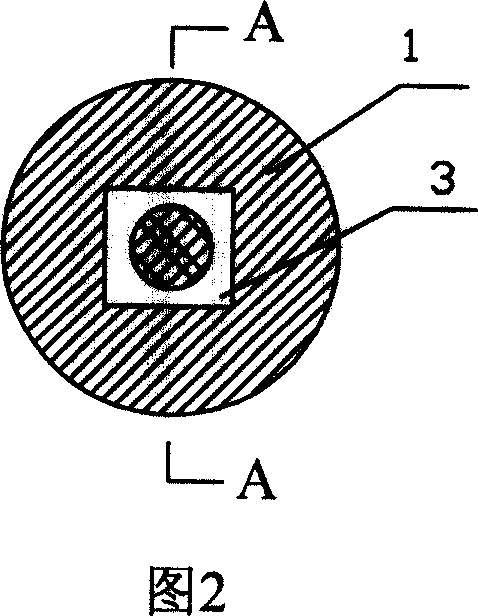

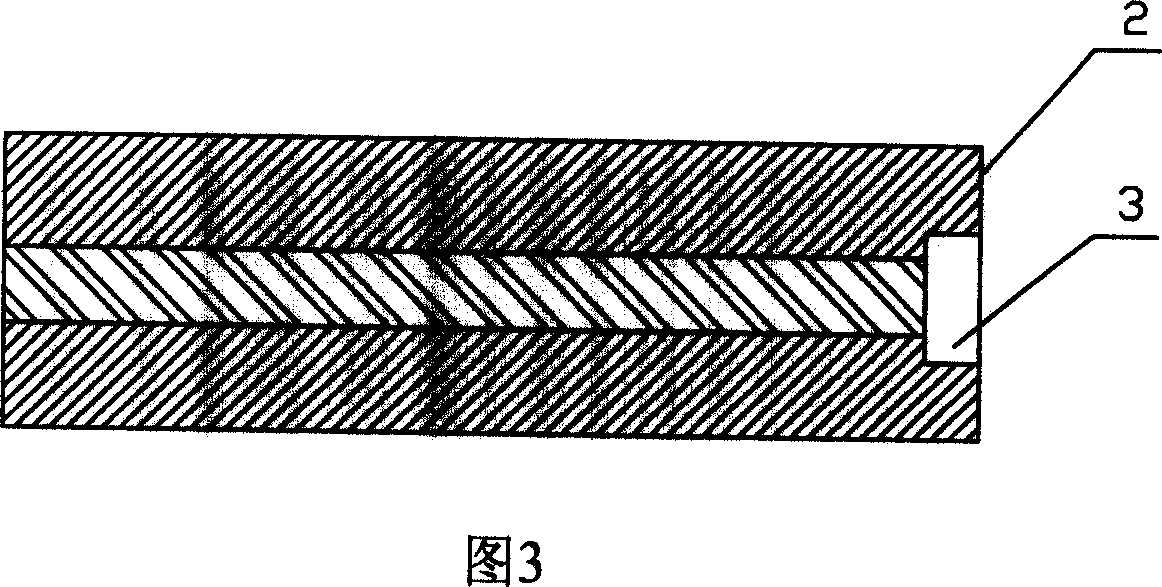

[0034] Step 1. Machining a cube-shaped microgroove 3 with a length of 10 microns and a width of 10 microns on the end face 2 of the single-mode silica fiber 1 with a depth of 30 microns, as shown in FIGS. 2 and 3 .

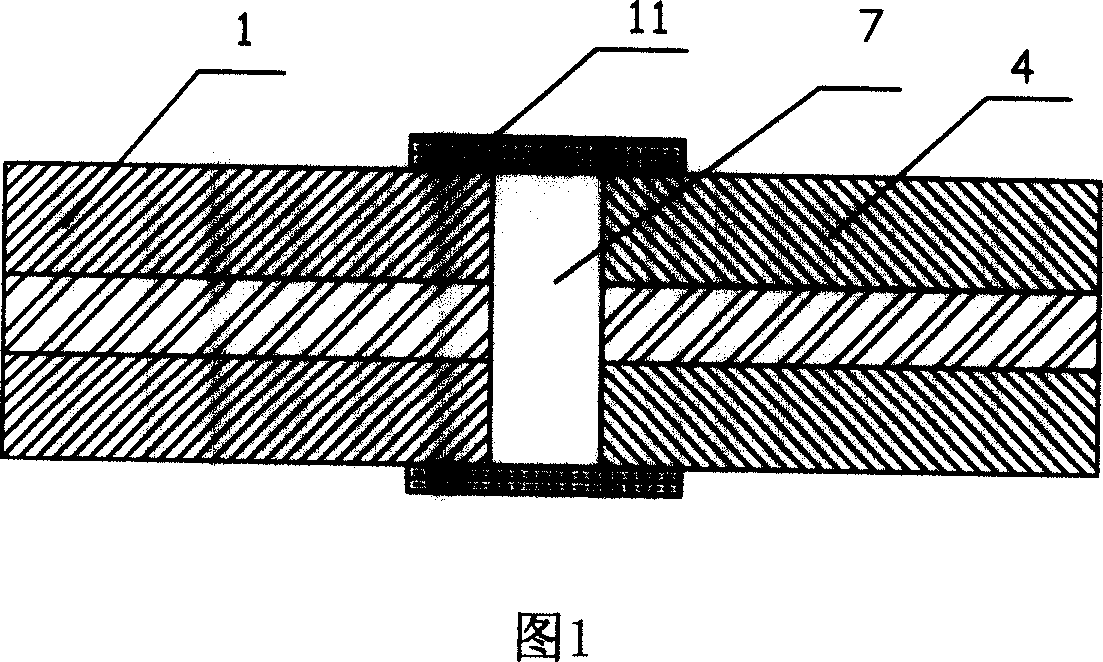

[0035] Step 2, outside the microgroove 3 of the quartz optical fiber 1 processed in step 1, a section of single-mode quartz optical fiber 4 is welded by an arc of an ordinary fusion splicer to form an optical fiber temperature and strain sensor, as shown in Figure 4, the optical fiber method The reflectance spectra of the temperature and strain sensors are shown in Figure 9, and the contrast of the reflective stripes is above 10dB.

[0036] When in use, the fabricated optical fiber Fab temperature and strain sensor can be packaged on the base material or used directly.

Embodiment 2

[0037] Embodiment 2: Manufacture fiber optic Fabulous temperature, strain sensor

[0038] Step 1. Process a cylindrical microgroove 3 on the end face 2 of the multimode gem fiber 1 with an ultraviolet laser, as shown in FIG. 5 .

[0039] Step 2. Connect a section of multimode gem fiber 4 outside the microgroove 3 of the multimode gem fiber 1 processed in step 1. A cylindrical microgroove 5 is processed on the end surface of the multimode gem fiber 4 . The micro-groove 3 and the micro-groove 5 are oppositely connected to each other to form an optical fiber Fappau temperature and strain sensor, as shown in FIG. 6 .

Embodiment 3

[0040] Embodiment 3: Manufacture fiber optic Fabulous temperature, strain sensor

[0041] Step 1. Process a cylindrical microgroove 3 on the end face 2 of the single-mode quartz optical fiber 1 with an ultraviolet laser.

[0042] Step 2, a section of single-mode quartz fiber 4 is fused outside the microgroove 3 of the silica fiber 1 processed in step 1 to form an optical fiber Fab temperature and strain sensor. The reflection spectrum of the optical fiber Fab temperature and strain sensor is shown in Figure 10 It shows that the contrast of reflection fringes is over 25dB.

[0043] When in use, the fabricated optical fiber Fab temperature and strain sensor can be packaged on the base material or used directly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com