Automatic filmcutting and laminating device and filmcutting and laminating integrated packing method

A film covering and equipment technology, applied in the field of film automatic packaging devices, can solve the problems of affecting the surface quality of products, low efficiency, easy scratches and surface defects of products, etc., to achieve the protection of appearance and surface state, good film covering effect, Applicability and site suitability for a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

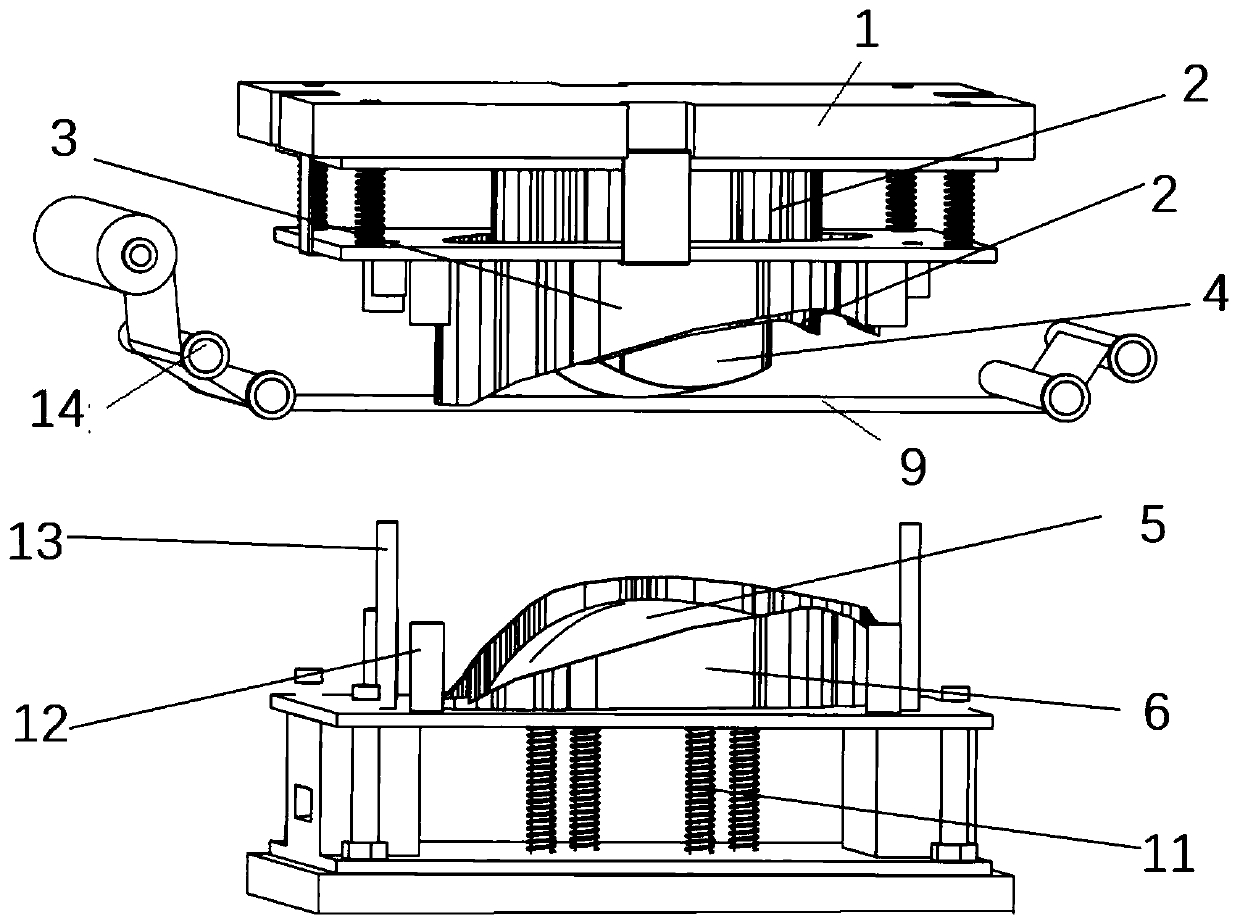

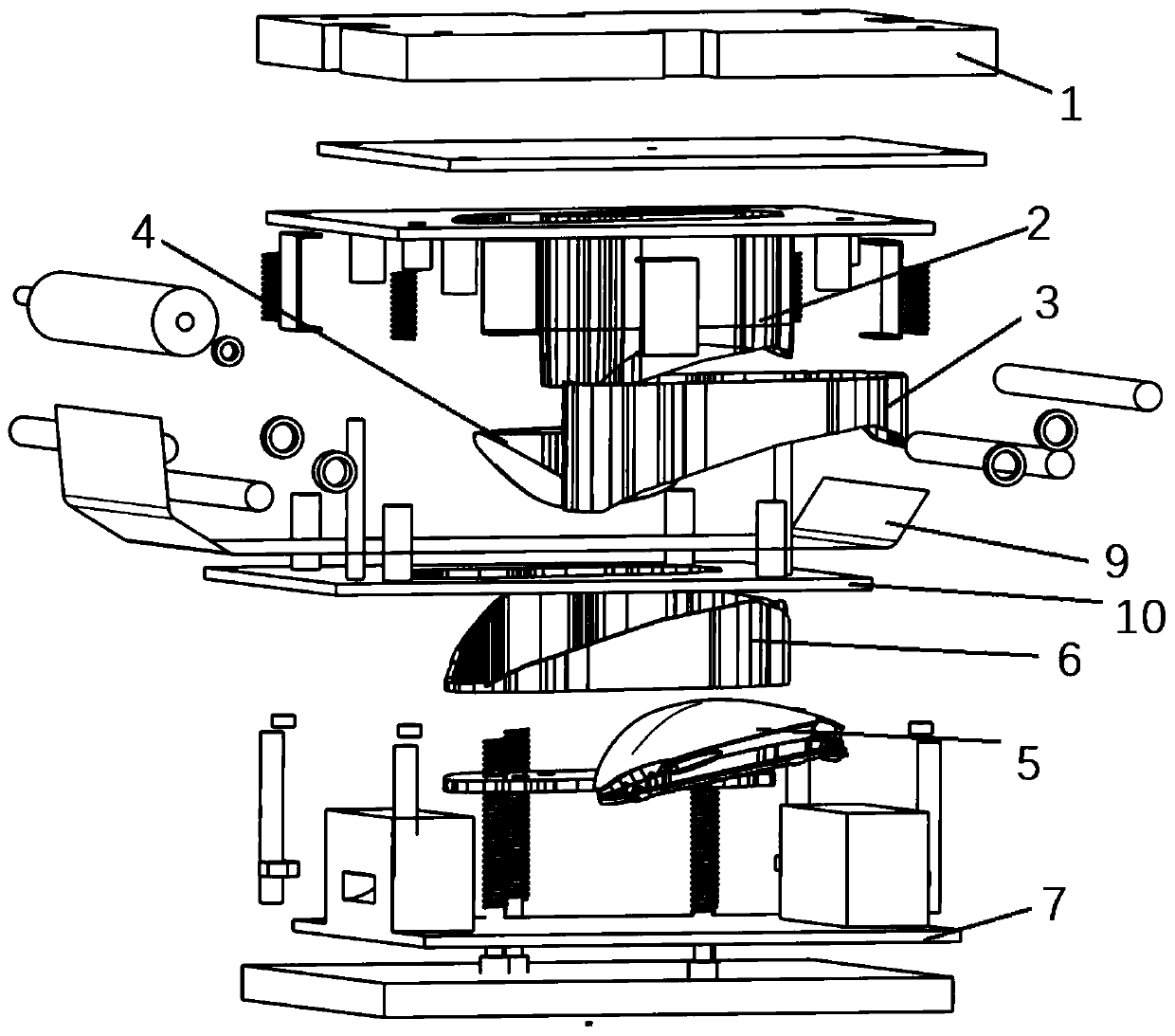

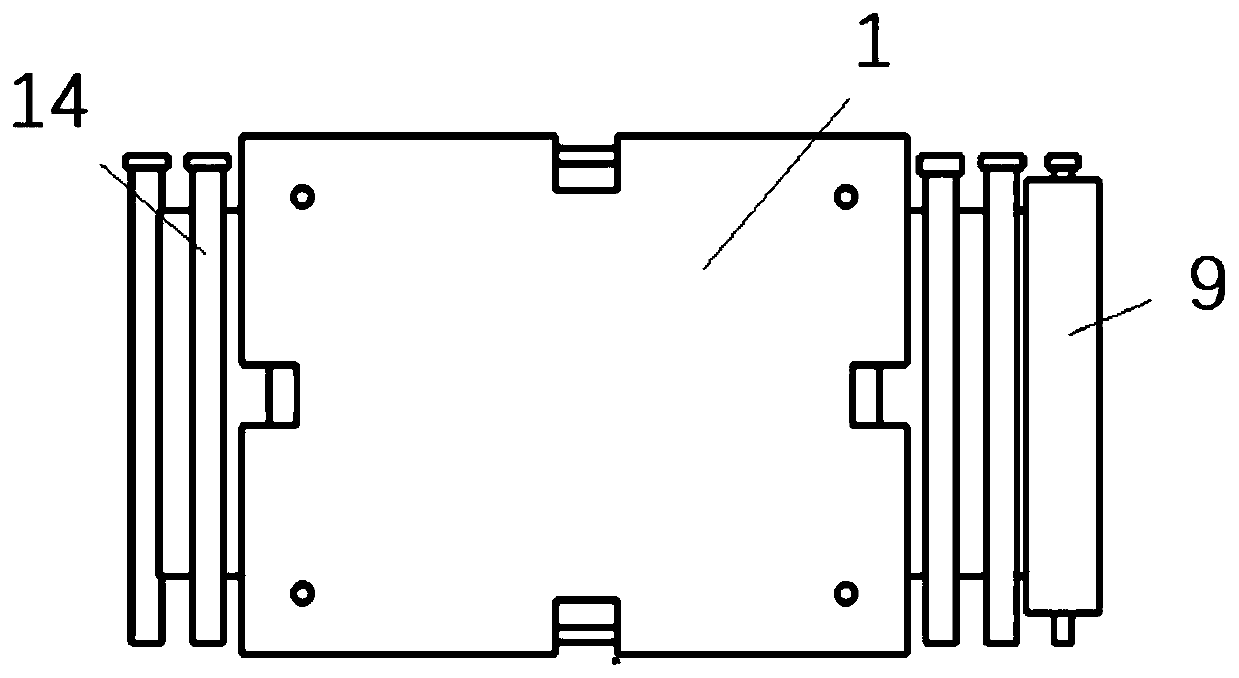

[0041] According to the automatic film cutting equipment implemented in the present invention, such as Figure 1-5 As shown, for complex surface products 5 (complex irregular shapes and structures, polyhedral products, curved surface products, are not limited to the products listed in the two embodiments of the present invention, in this embodiment it is as Figure 4 The car lamps with complex curved and non-curved structures shown are not limited to the products listed in the embodiments of the present invention) are packaged with protective film and cut film. Features include:

[0042]A pair of cutting and laminating profiling molds (3, 6) that are set up and down opposite each other, and whose inner wall contours are basically consistent with the shape of the junction of the product to be packaged; the cutting and laminating profiling molds (3, 6) are all closed at one end The hollow cover with the other end open is cylindrical; the product fixing device (such as figure 1...

Embodiment 2

[0065] like Figure 6-8 As shown, the difference from Example 1 is that the automatic film cutting equipment is aimed at another kind of irregular complex surface product 5-1 (such as Figure 8 Shown has complex curved surface and non-curved surface structure), and according to product size and row shape considerations, in this embodiment, the undercut film profiling mold can be optionally omitted (of course, the undercut film can also be set as in Example 1 profiling mold), only the top-cut film-coated profiling mold 3-1 whose inner wall profile is basically consistent with the shape of the product 5-1.

[0066] Same as Embodiment 1, in this implementation, a cylinder-shaped profiling tool 2-1 whose inner cavity is consistent with the shape of the product 5-1 is also provided. The cavity of the mold 3-1 is set, and can cut the protective film 9 by going down with the pressing force when the upper cutting film profiling mold 3-1 is pressed down.

[0067] A profiling flexible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com