Automatic sizing device of aluminum bar sawing machine

A sawing machine and cutting-to-length technology, which is applied to the attachment of sawing machines, metal sawing equipment, metal processing machinery parts, etc., can solve the problems of heavy workload, easy to hurt fingers, and potential safety hazards for operators, and avoid Potential safety hazards, improving sawing precision, and reducing labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

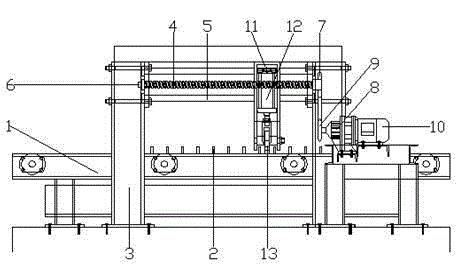

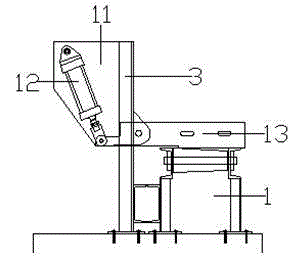

[0013] Such as figure 1 , figure 2 As shown, it includes a transmission track 1, a scale mark 2, a frame 3, an adjustment screw 4, a polished rod 5, a reducer 8, a stepping motor 10, a cylinder 12 and a scale baffle 13. The upper part of both sides of the transmission track 1 is respectively provided with a scale mark 2, the side of the transmission track 1 is provided with a frame 3; Polishing rods 5 are respectively provided.

[0014] An encoder 6 is installed at one end of the adjusting screw mandrel 4, and a driven sprocket 7 is installed at the other end; the driven sprocket 7 is connected to the driving sprocket 9 arranged on the reducer 8 through a chain, and the reducer 8 is connected to the stepping motor 10; The polished rod 5 and the adjusting screw rod 4 are sleeved with a cavity sizing device bracket 11; the sizing device bracket 11 is internally provided with a cylinder 12 with a plunger downward, and the bottom end of the cylinder 12 is connected with a frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com