A quick-change tooling for end-face processing of multi-standard steel pipes

A technology of end face processing and multiple specifications, which is applied in the direction of metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve the problems of low processing efficiency, time-consuming and laborious, and increase production costs, so as to improve processing efficiency and reduce production costs , The effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

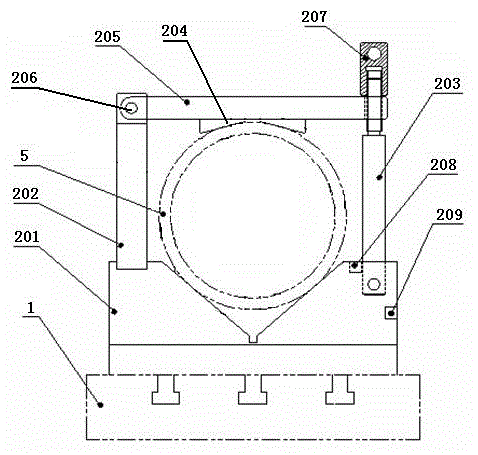

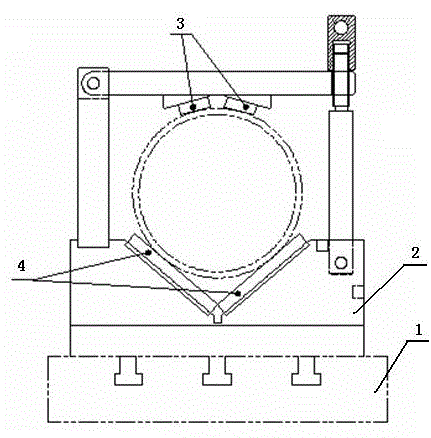

[0025] Such as figure 1 The shown multi-standard steel pipe end face processing quick-change tooling 2 is installed on a workbench 1 with a T-shaped groove, and the quick-change tooling 2 is welded by Q345 steel plates. The quick-change tooling 2 includes a V-shaped supporting base 201 installed on the T-shaped groove, and a pressing plate column 202 and a pressing rod 203 installed on the left and right ends of the V-shaped supporting base 201 . Wherein, the pressing plate column 202 is fixed on the V-shaped supporting base 201, and the pressing rod 203 is connected with the V-shaped supporting base 201 through the pin shaft 206, so the pressing rod 203 can freely rotate and open with the pin shaft 206 as the base point. The outer circle of the lower part of the V-shaped support base 201, the upper pressing plate 205 is arranged transversely on the upper part of the pressing plate column 202 and the pressing rod 203, and the V-shaped pressing block 204 is arranged under the u...

Embodiment 2

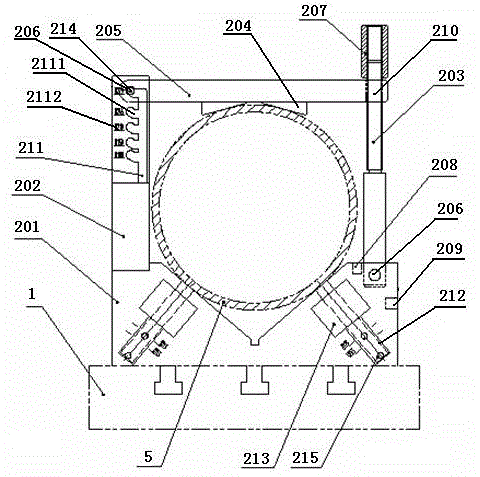

[0030] When processing steel pipes with different pipe diameters, in addition to using the method of adding pads in the first embodiment, an adjustment mechanism can be added on the basis of the quick-change tooling 2 provided in the first embodiment. The specific structure is as follows: Figure 3 ~ Figure 5 As shown, the top of the pressure plate column 202 of the quick-change tool is provided with an upper pressure plate chute 211. According to the steel pipe size of various specifications to be processed, a plurality of card slots 2111 are arranged in the upper pressure plate chute 211, and each side of the card slot 2111 is preferably The engraved line 2112 of the steel pipe size of each specification is set, so that the operator can quickly adjust the quick-change tooling according to the steel pipe size to be processed. When the upper pressing plate 205 is opened, the pin shaft 206 can slide in the upper pressing plate chute 211 of the pressing plate column 202; further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com