Assembly device and method for welded ball net frame unit

An assembly device, welding ball technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of prolonging the assembly cycle and cost of the grid frame, the large number of supporting measures, and the slow speed of multiple parts. Assembly efficiency and precision, light weight, fast conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

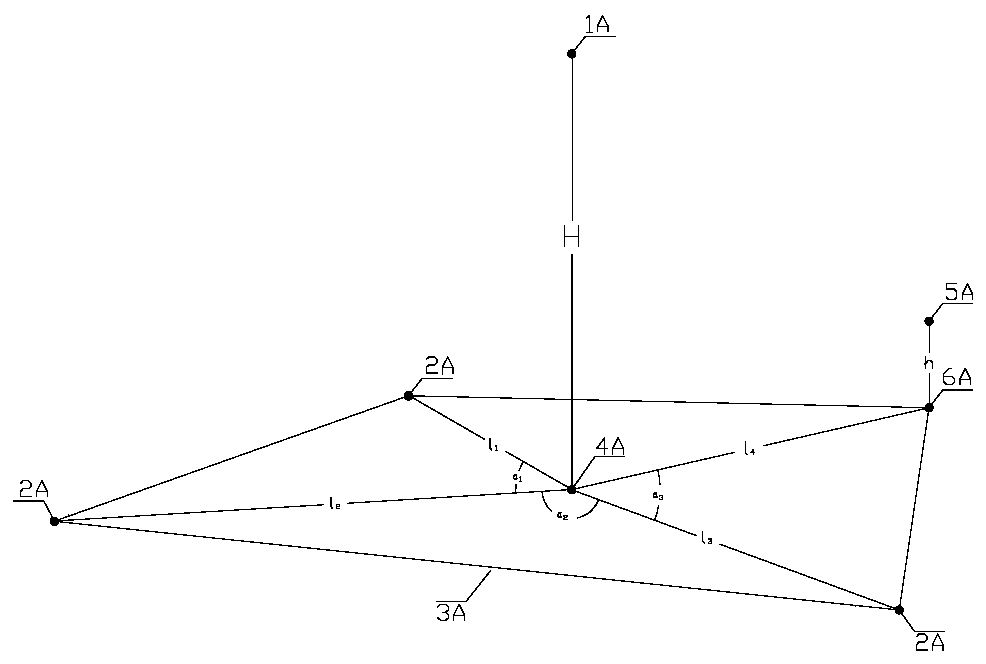

[0037] like figure 1 As shown, firstly, the surface formed by connecting the three lower string ball center points 2A in the grid assembly unit model is used as the reference plane 3A, and the distance H from the upper string ball center point 1A to the reference plane 3A is measured. Then the upper string center point 1A and the fourth lower string center point 5A are projected onto the datum plane 3A to obtain the projection point 4A and the projection point 6A, and the distance 1 between the lower string center point 2A and the projection point 6A to the projection point 4A is measured 1 , l 2 , l 3 , l 4 and angle α 1 、α 2 and alpha 3 , and the distance h from the center point 5A of the bottom string to the projection point 6A. Adjust the assembly device through the above positioning parameters, and carry out the assembly operation of the grid unit.

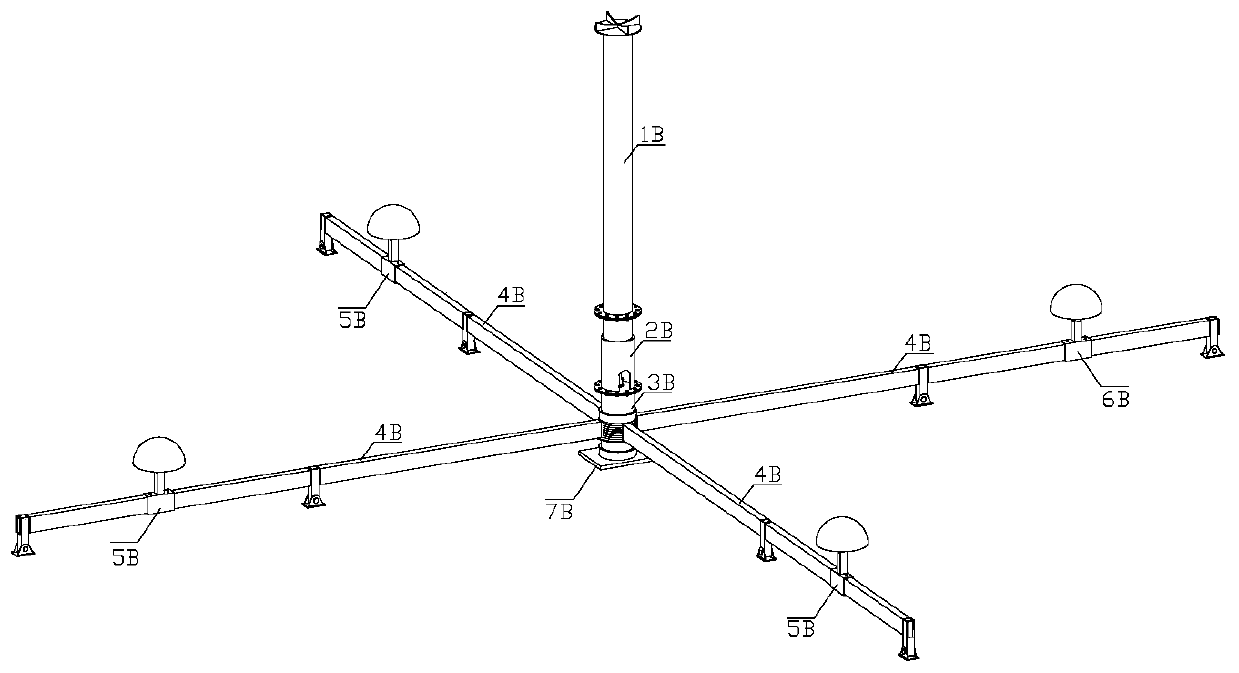

[0038] like figure 2 As shown, the device mainly includes: standard pole section 1B, pole height adjustment sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com