Cutter head components mechanism for lining and cutting

A technology of cutter head assembly and cutting mechanism, which is applied in glass cutting device, glass manufacturing equipment, metal processing, etc., can solve the problems of complex structure, low scribing and cutting precision, different process requirements, etc., and achieve simple and reasonable structure, solve Scribing cutting accuracy is not high, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

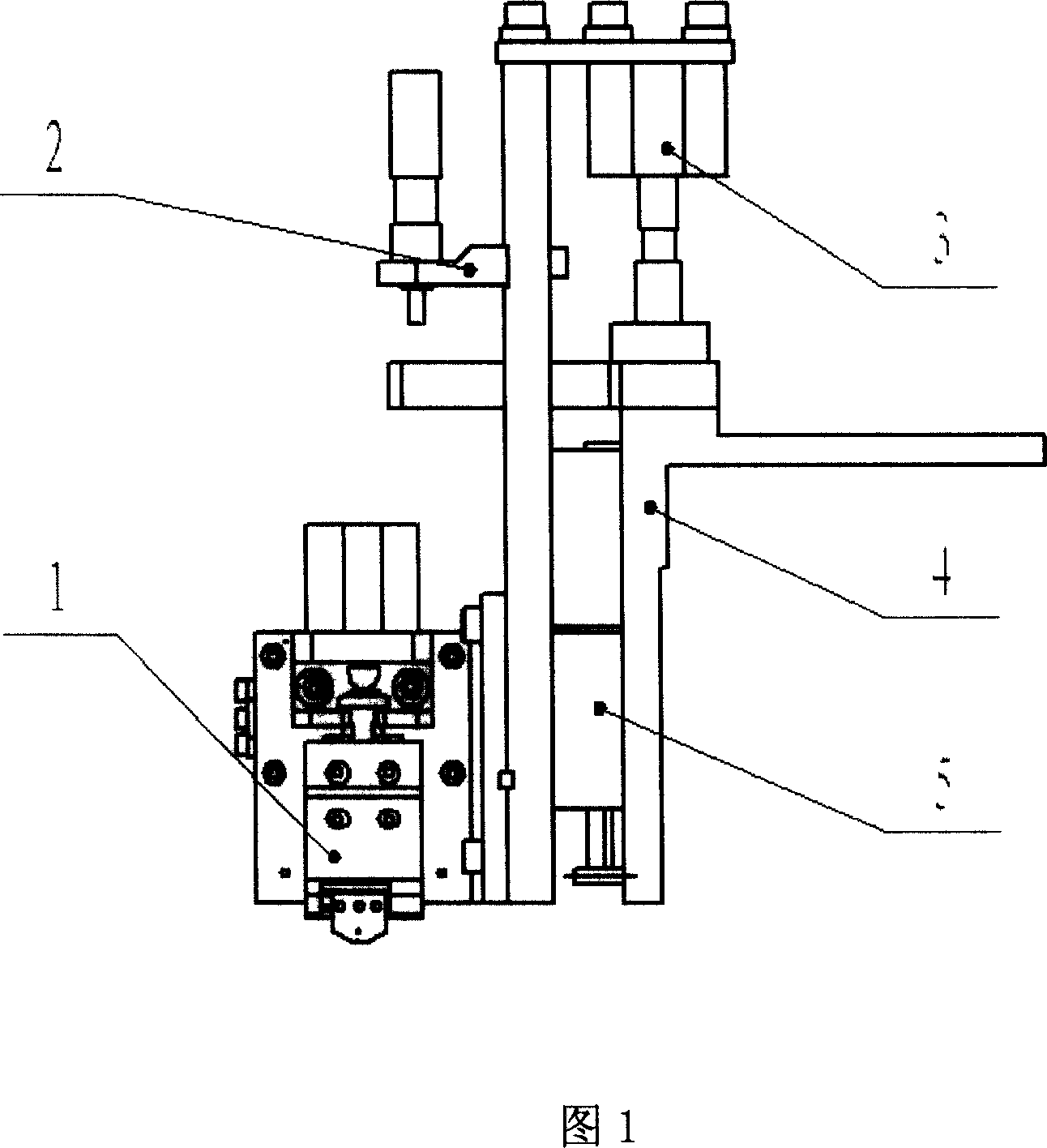

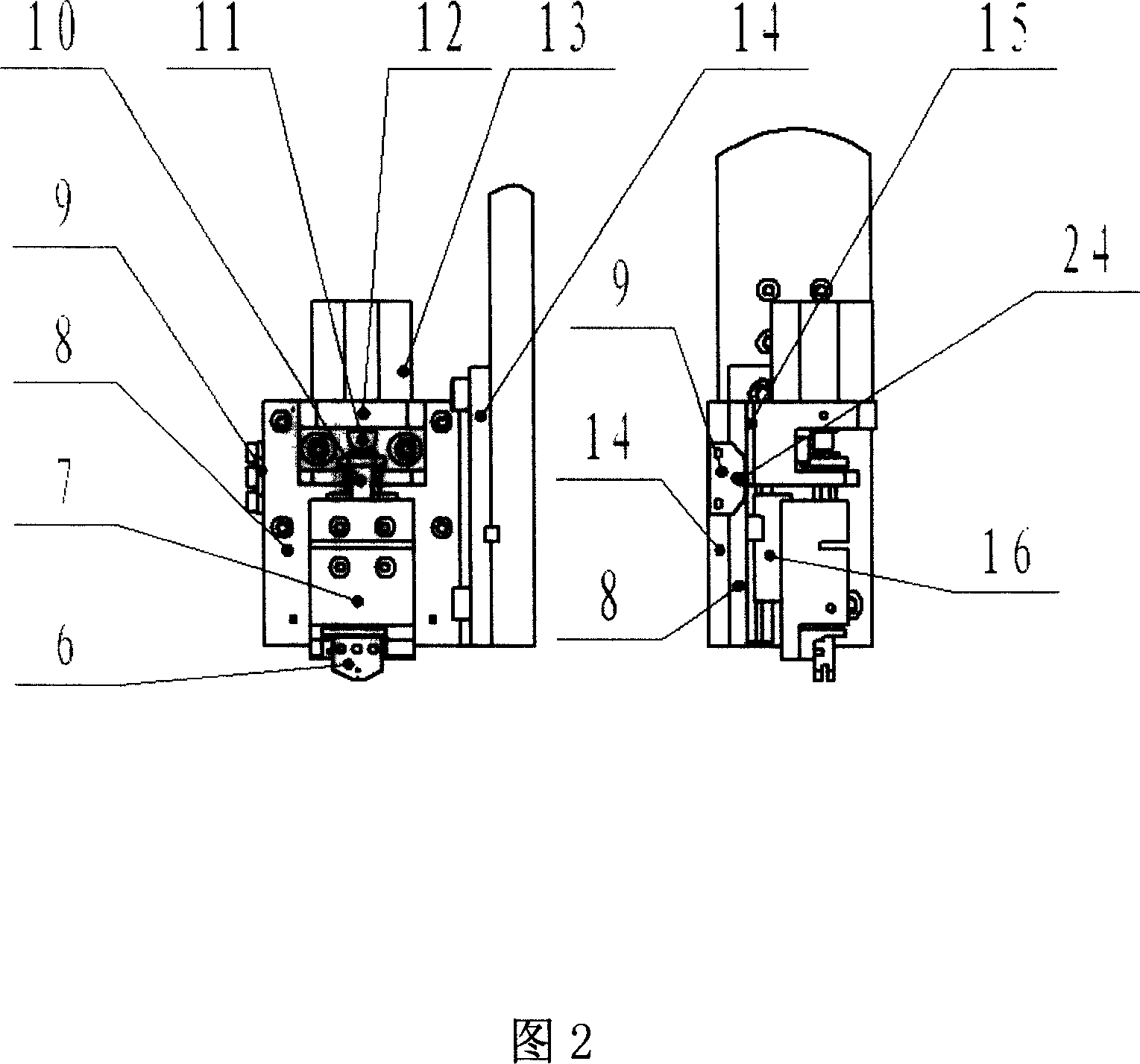

[0013] The cutter head assembly is composed of a cutting mechanism 1, a limit mechanism 2, an up and down moving mechanism 3, a fixed reference member 4, a guide assembly 5 and other components.

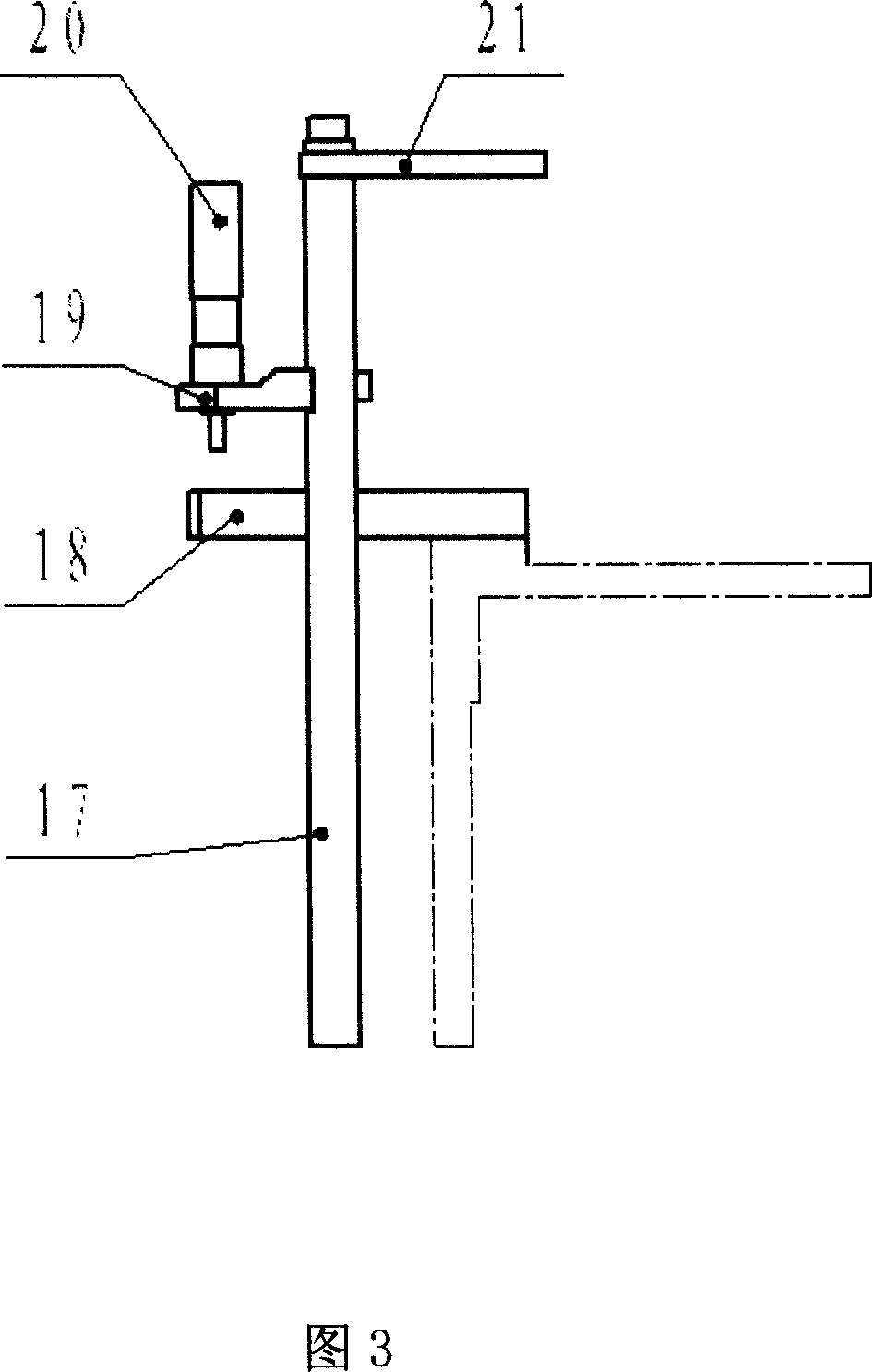

[0014] In the cutting mechanism 1, the adjusting fixed plate 14 is fixedly connected on the mounting plate 17, the front and rear adjusting plates 8 are fixedly connected with the adjusting fixed plate 14, and the adjusting fixed plate 9 is installed on the adjusting fixed plate 14 of the front and rear adjustment, and is installed on the adjusting fixed plate. The top wire on the 9 pushes and pulls the front and rear adjusting plate 8 by rotating in both forward and reverse directions, so the front and rear adjustment of the cutter head is realized in the cutting mechanism 1. The pressure cylinder 13 is fixedly connected on the cylinder block 12, and the cylinder block 12 is designed with a via hole, which facilitates the extension and retraction of the cylinder joint 11 connected on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com