Building hoist stand column port cutting fixture and machining method of stand column port

A construction lift and cutting technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem of low cutting precision of column ports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

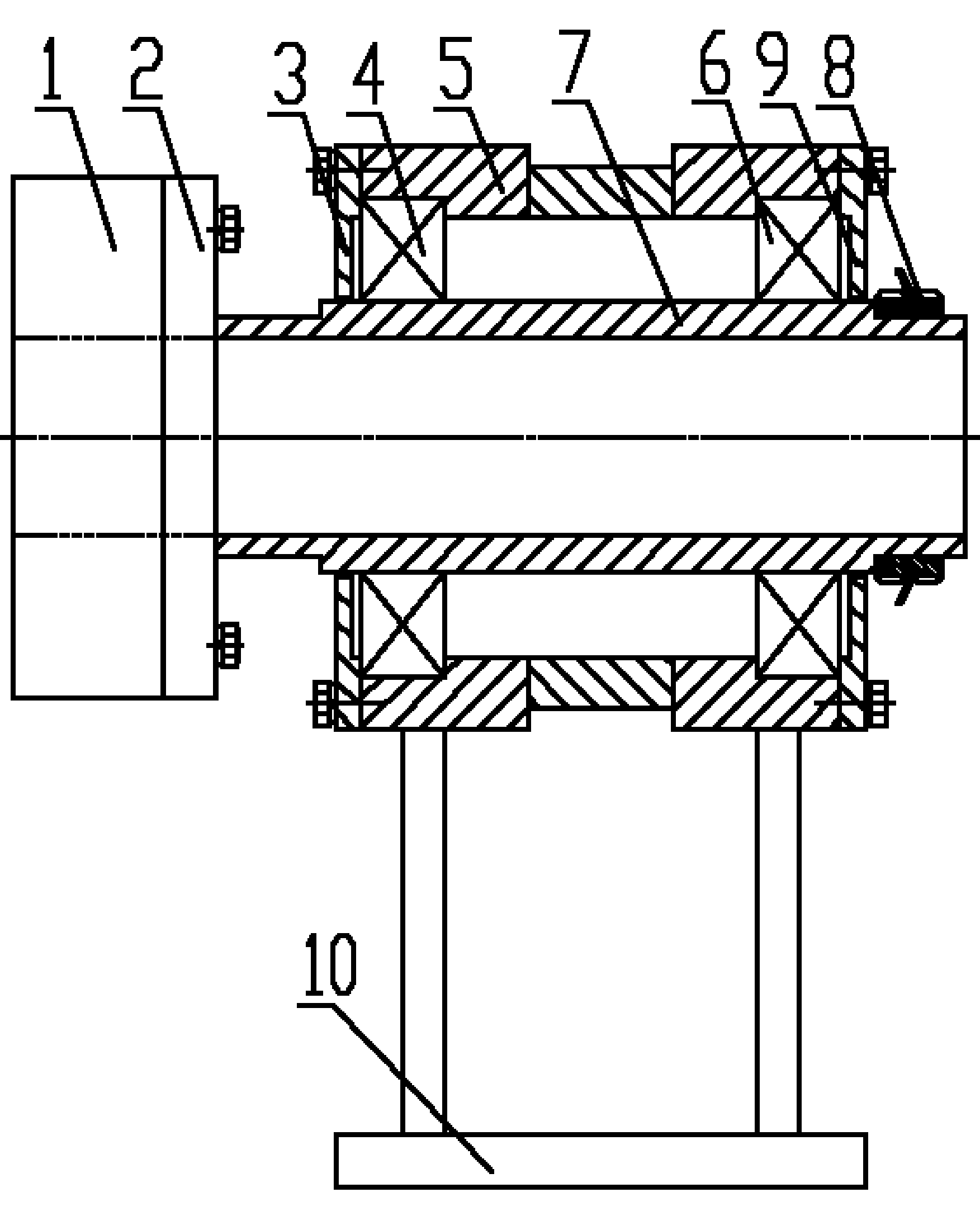

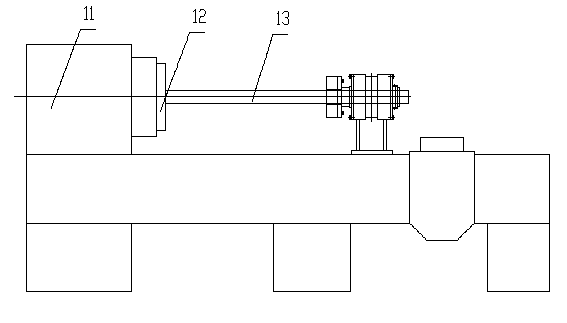

[0016] Such as figure 1 The shown construction lift column port cutting fixture has a fixture seat 10 that is installed on the guide rail of the lathe bed, and the bottom is matched with the lathe bed guide rail. The bottom of the fixture seat 10 is provided with a groove, and the V-shaped guide rail and Rectangular guide rails cooperate to facilitate accurate positioning during installation. The shaft sleeve 5 is fixedly connected to the upper part of the fixture seat 10. The two ends of the shaft sleeve 5 have bearing seats, and the outer rings of the first bearing 4 and the second bearing 6 Fitted and installed in the bearing housings at both ends of the shaft sleeve 5 respectively, the hollow rotating shaft 7 is fitted in the inner rings of the first bearing 4 and the second bearing 6, and the flange 2 rotates with the hollow The first end of the shaft 7 is fixedly connected, the first end cover 3 and the second end cover 9 are detachably connected to the two ends of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com