Tiltable edge treatment woodworking machine tool

A woodworking machine tool and bed technology, which is applied in the field of edge banding processing with straight lines and faces, and can solve problems such as low efficiency and unstable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

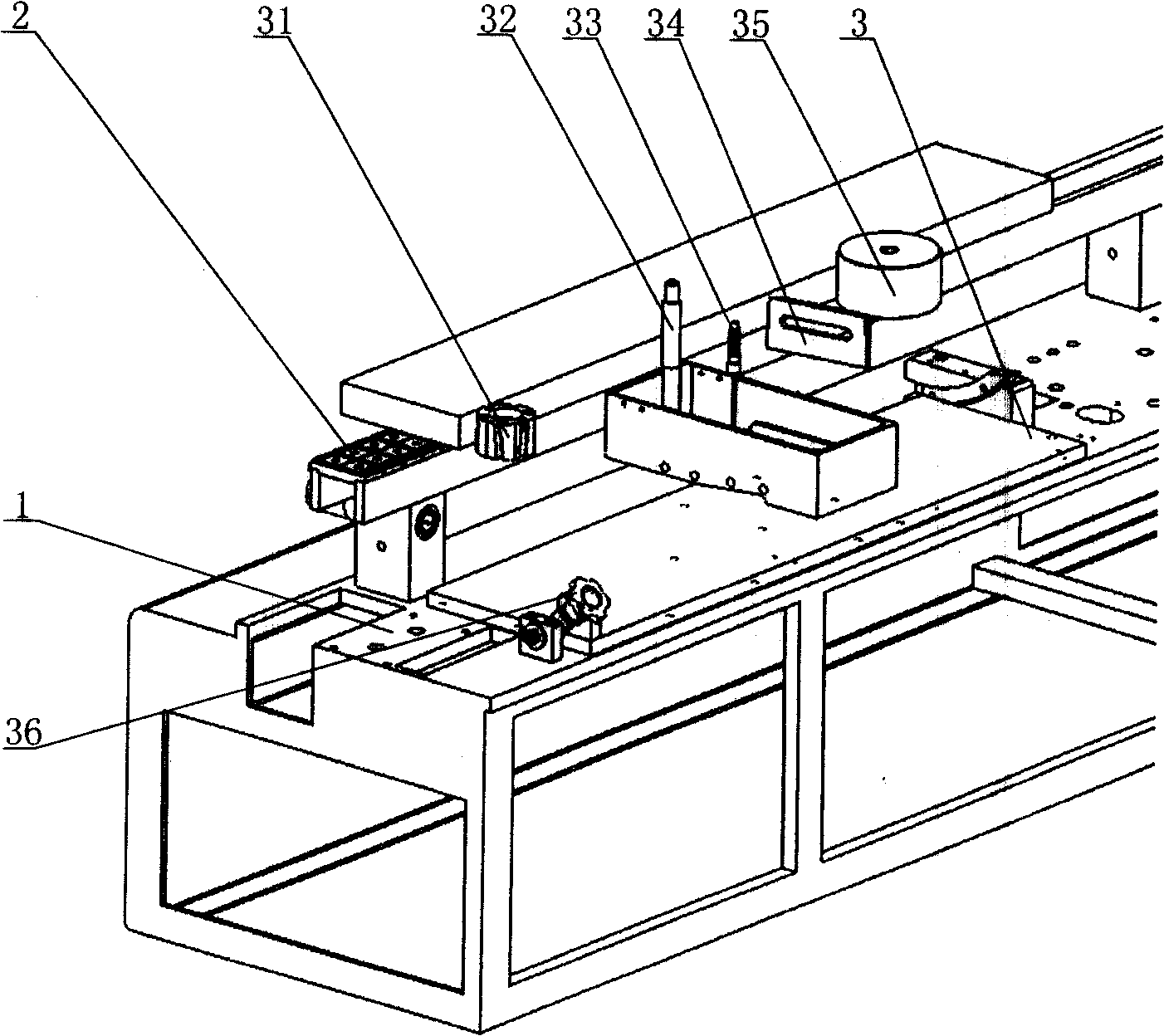

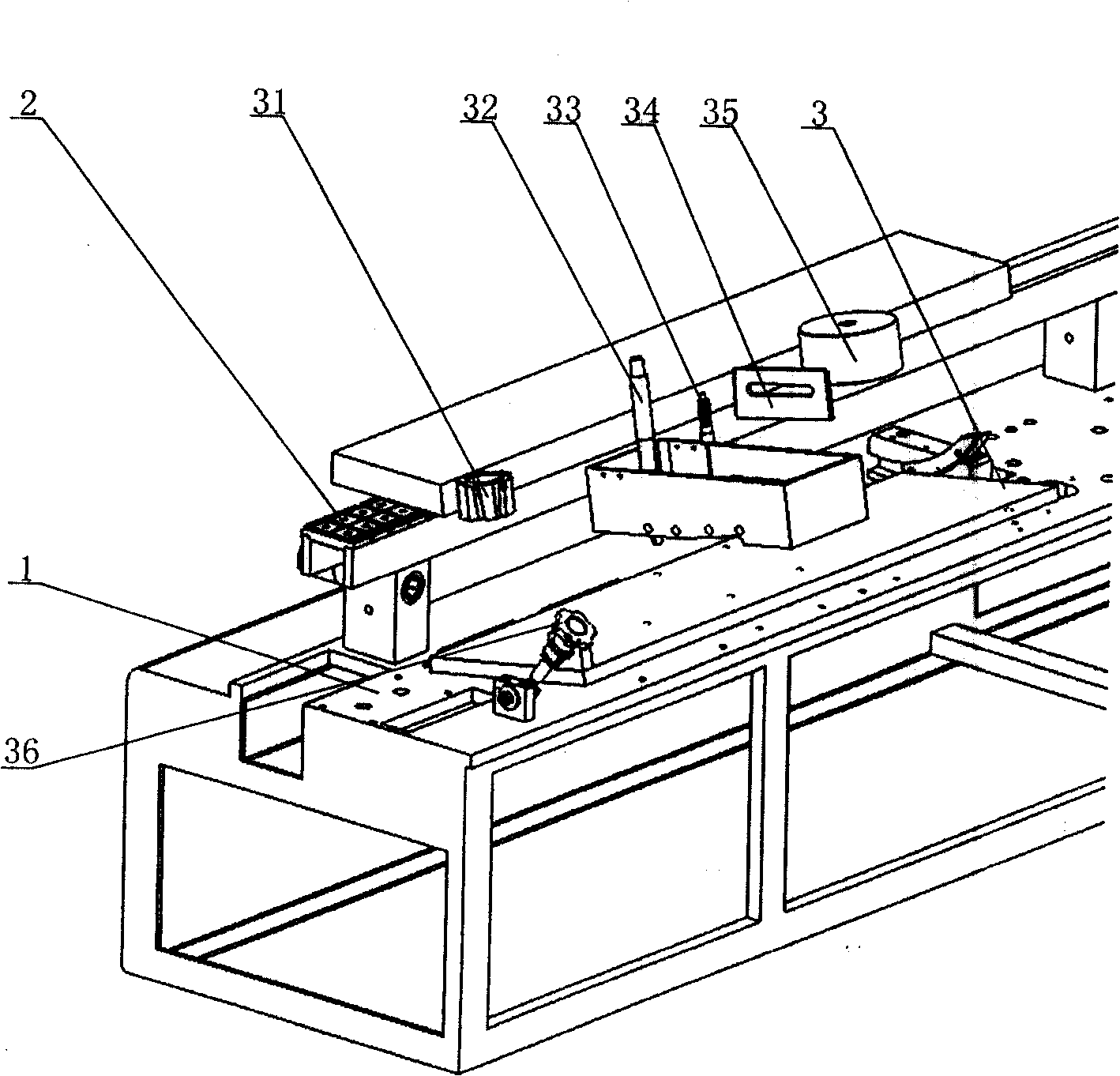

[0011] The tiltable edge banding woodworking machine of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 , figure 2 As shown, a tiltable edge banding woodworking machine tool includes a bed 1 and a workpiece conveying platform 2. Edge device 31, gluing device 32, tape feeding device 33, tape cutting device 34, edge holding device 35, and any combination of the above devices can also be configured as required.

[0013] During work, the workpiece to be edge-sealed is placed on the workpiece conveying platform 2, and according to the angle of the workpiece to be edge-sealed, the rotating adjustment mechanism 36 is rotated to adjust the angle of the tiltable workbench 3 so that the edge milling device 31, coating The glue device 32, the tape feeding device 33, the tape cutting device 34, and the edge pressing device 35 are respectively consistent with the angles of the workpiece to be edge-sealed, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com