Woodworking four-edge cutting machine

A cutting machine and four-sided technology, which is applied to wood processing appliances, sawing equipment, manufacturing tools, etc., can solve the problems of affecting processing accuracy, reducing production efficiency, and large longitudinal beam stress, and achieving extended service life, high processing efficiency, The effect of easy position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

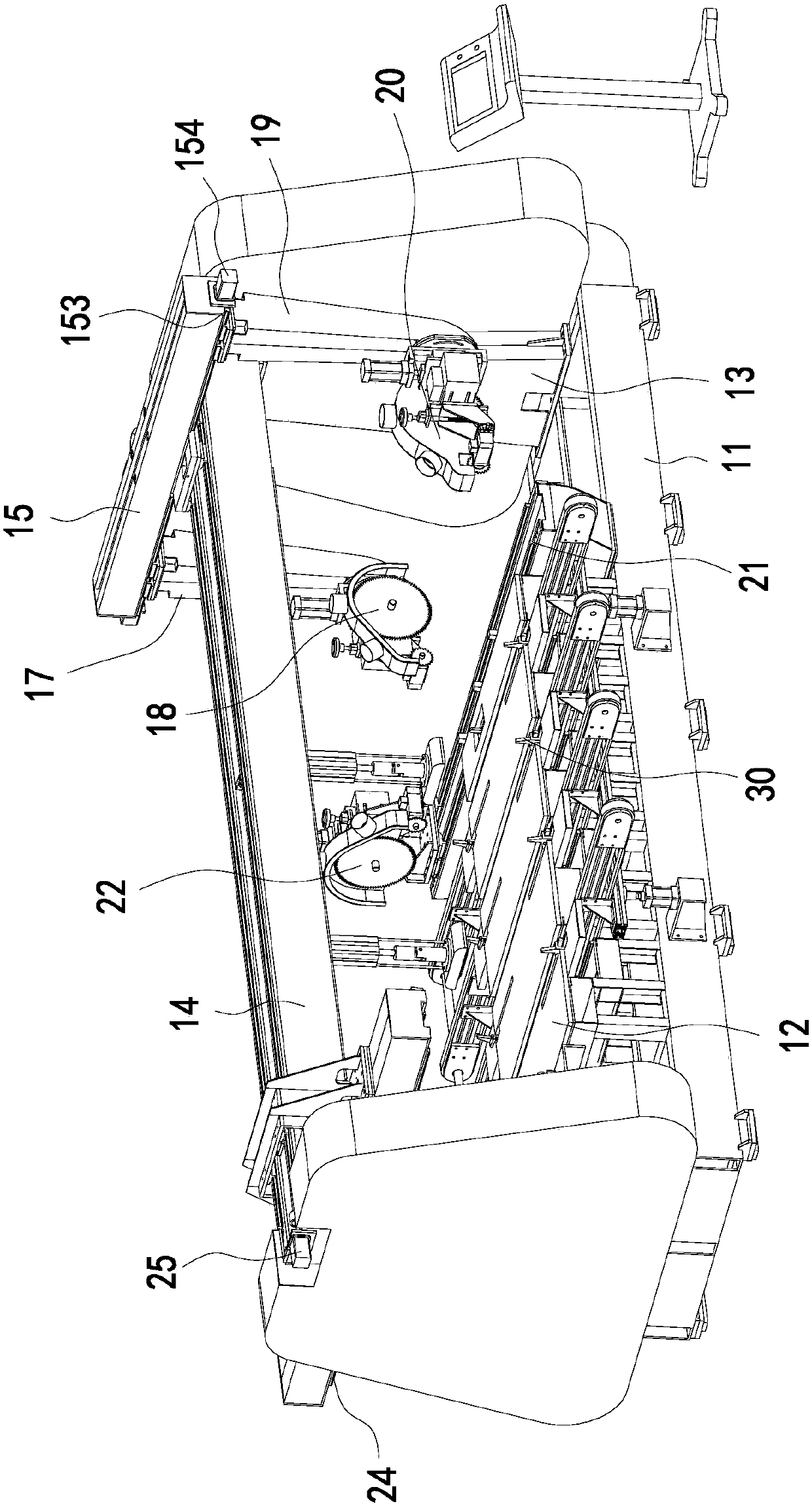

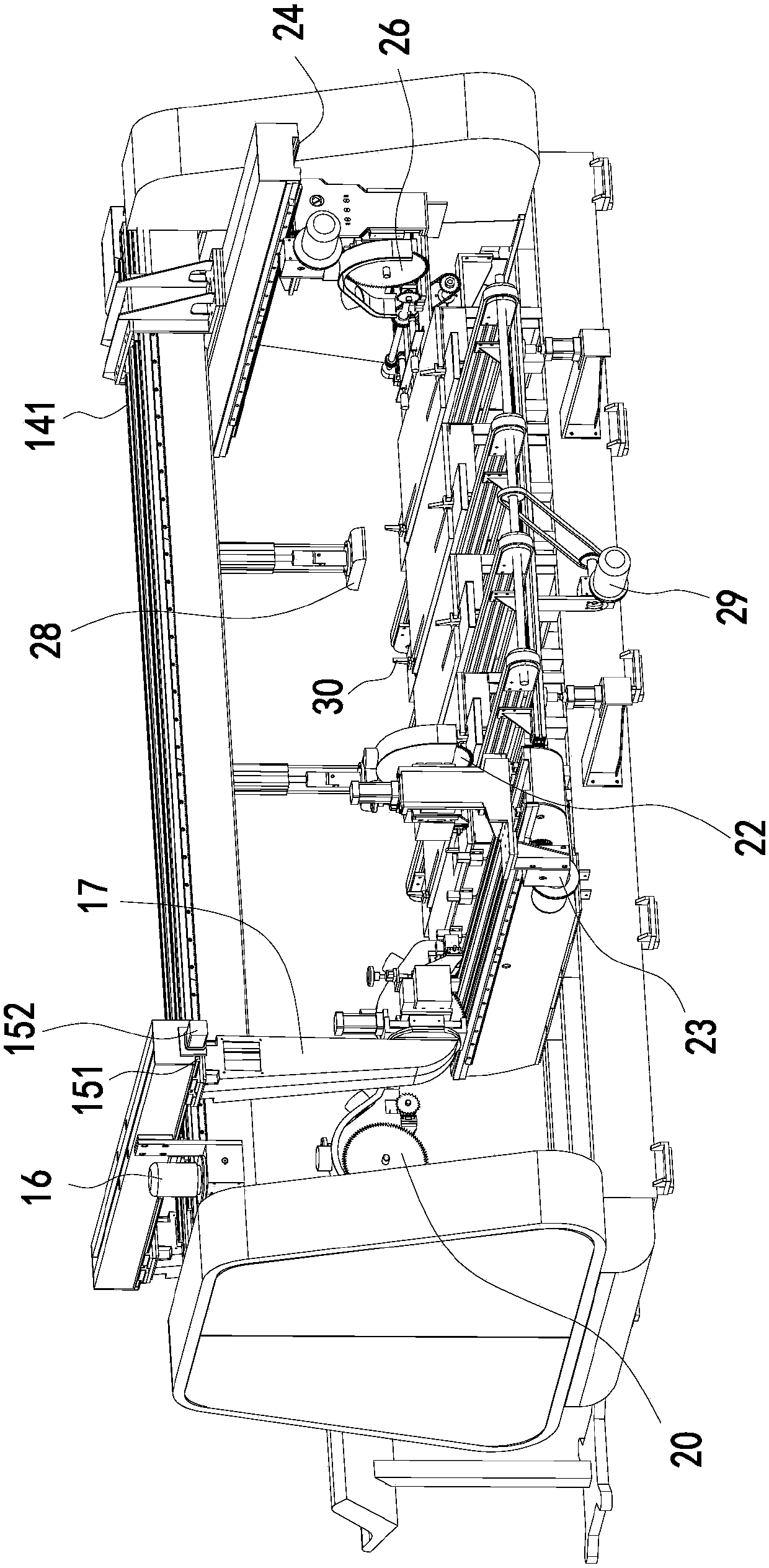

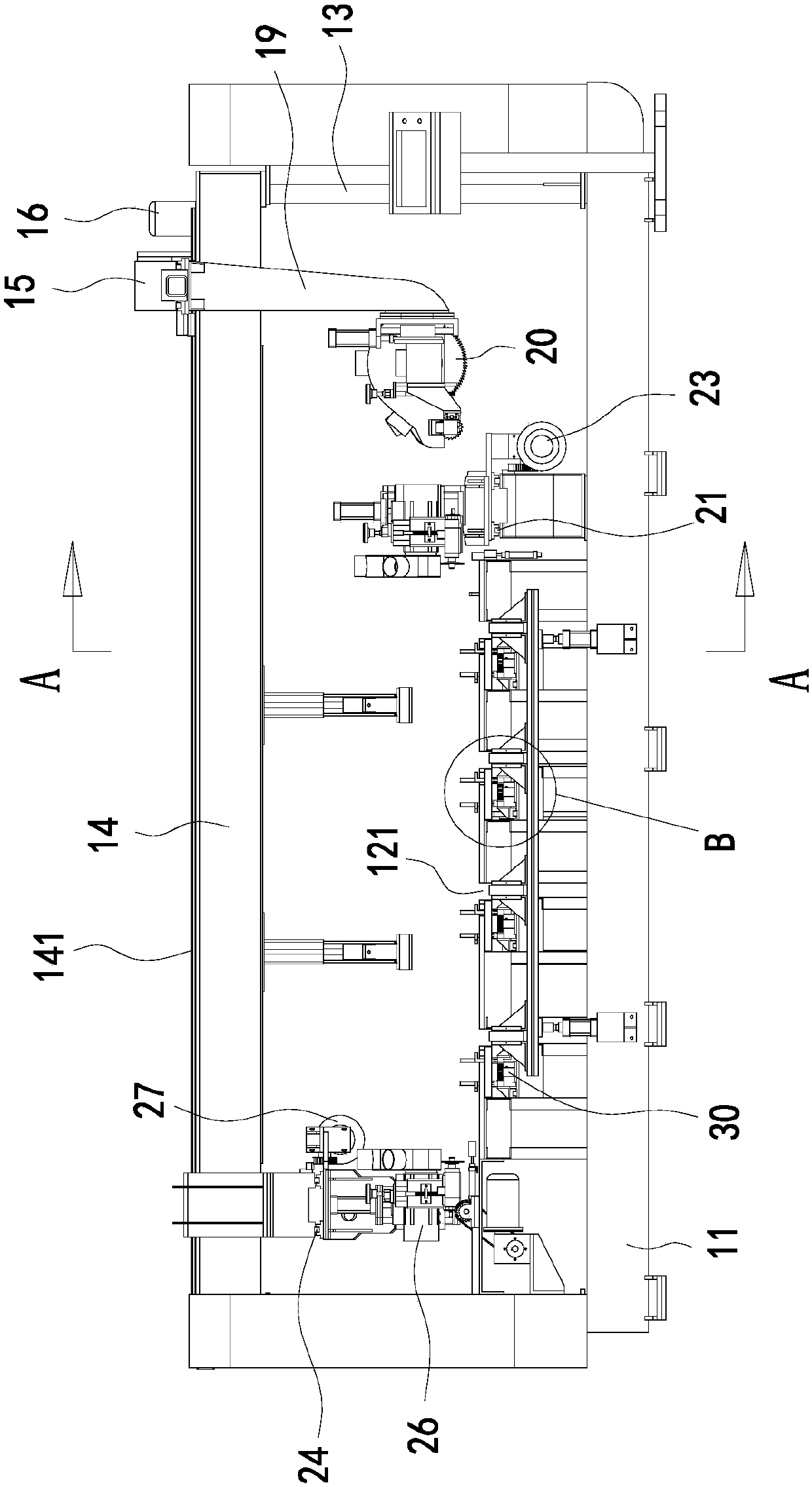

[0038] A woodworking four-sided cutting machine as shown in the figure includes a bed 11, a worktable 12 with a longitudinal groove 121, a column 13, a beam 14 with a transverse guide rail 141, and a longitudinal arrangement that can be moved along the transverse feed of the beam. Longitudinal beam 15, infeed mechanism 16 (it comprises rack 161, motor 162 and speed reducer 163, as Figure 4 ), the first boom 17, the first longitudinal adjustment mechanism (it includes the first longitudinal adjustment guide rail 151, motor 152 and lead screw nut pair, as Figure 6 ), the first horizontal cutting saw 18, the second boom 19, the second longitudinal adjustment mechanism (which includes the second longitudinal adjustment guide rail 153, motor 154 and lead screw nut pair, which are located at the lower end of the first boom 17, such as F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com