Woodworking machine comprising a linear direct drive

A technology of woodworking machine tools and driving devices, which is applied in the direction of electromechanical devices, sawing devices, feeding devices, etc., and can solve the problems of high cost of magnets, mechanical wear of mechanical transmission units, and reduced processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Before describing in detail the woodworking machine tool with a linear direct drive device, the working mode and feasible implementation of the linear direct drive device (hereinafter also referred to as "motor" or "linear motor") related to the woodworking machine tool will be introduced.

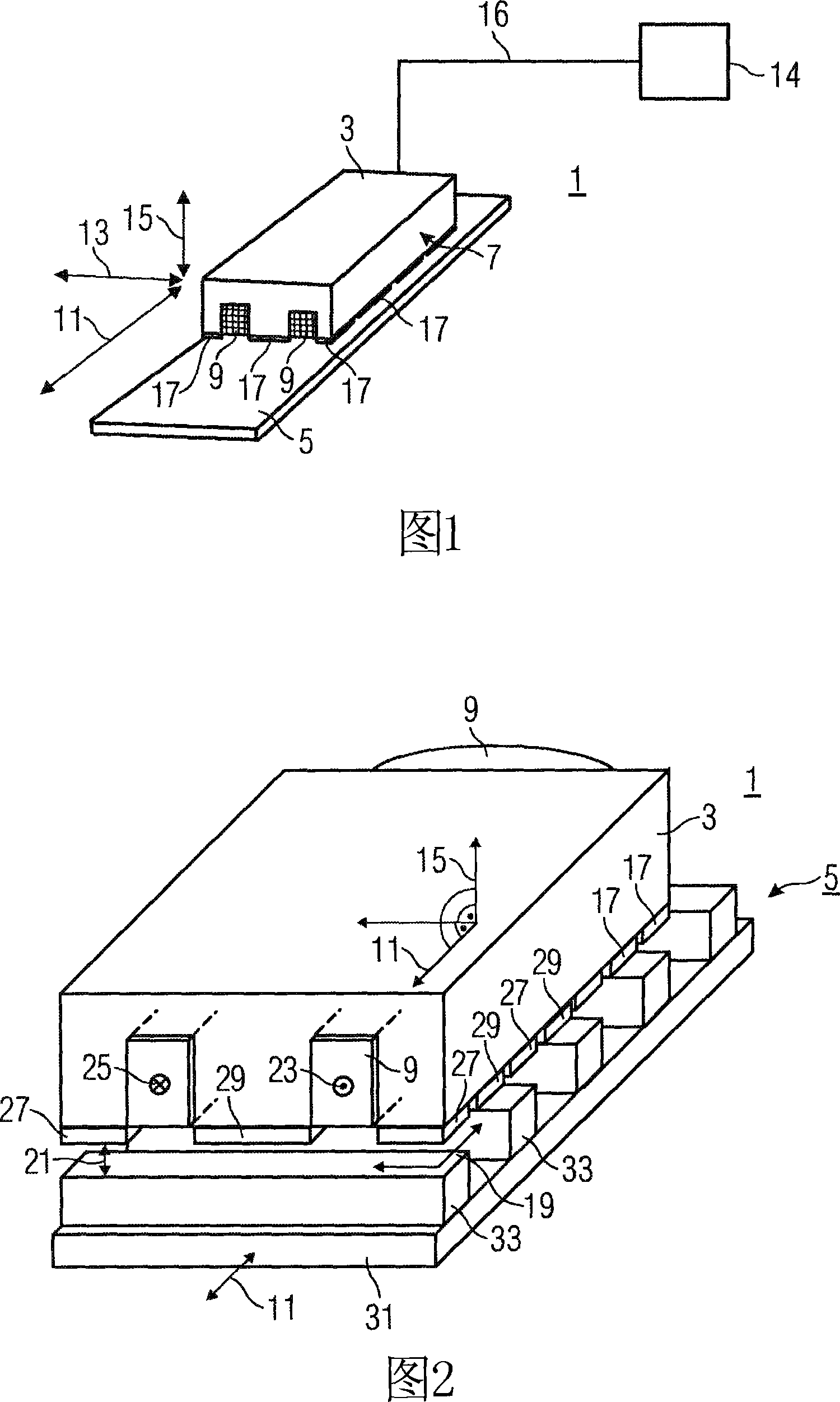

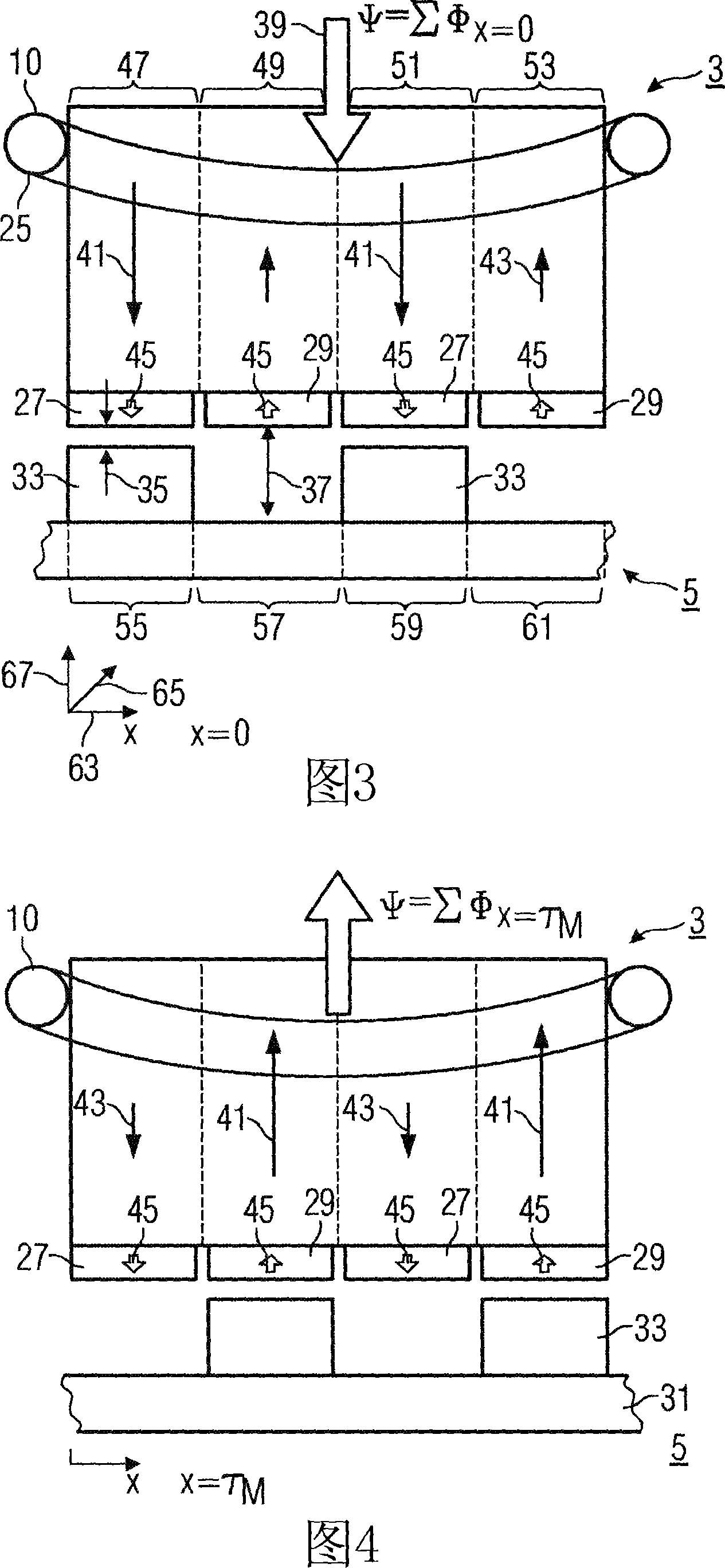

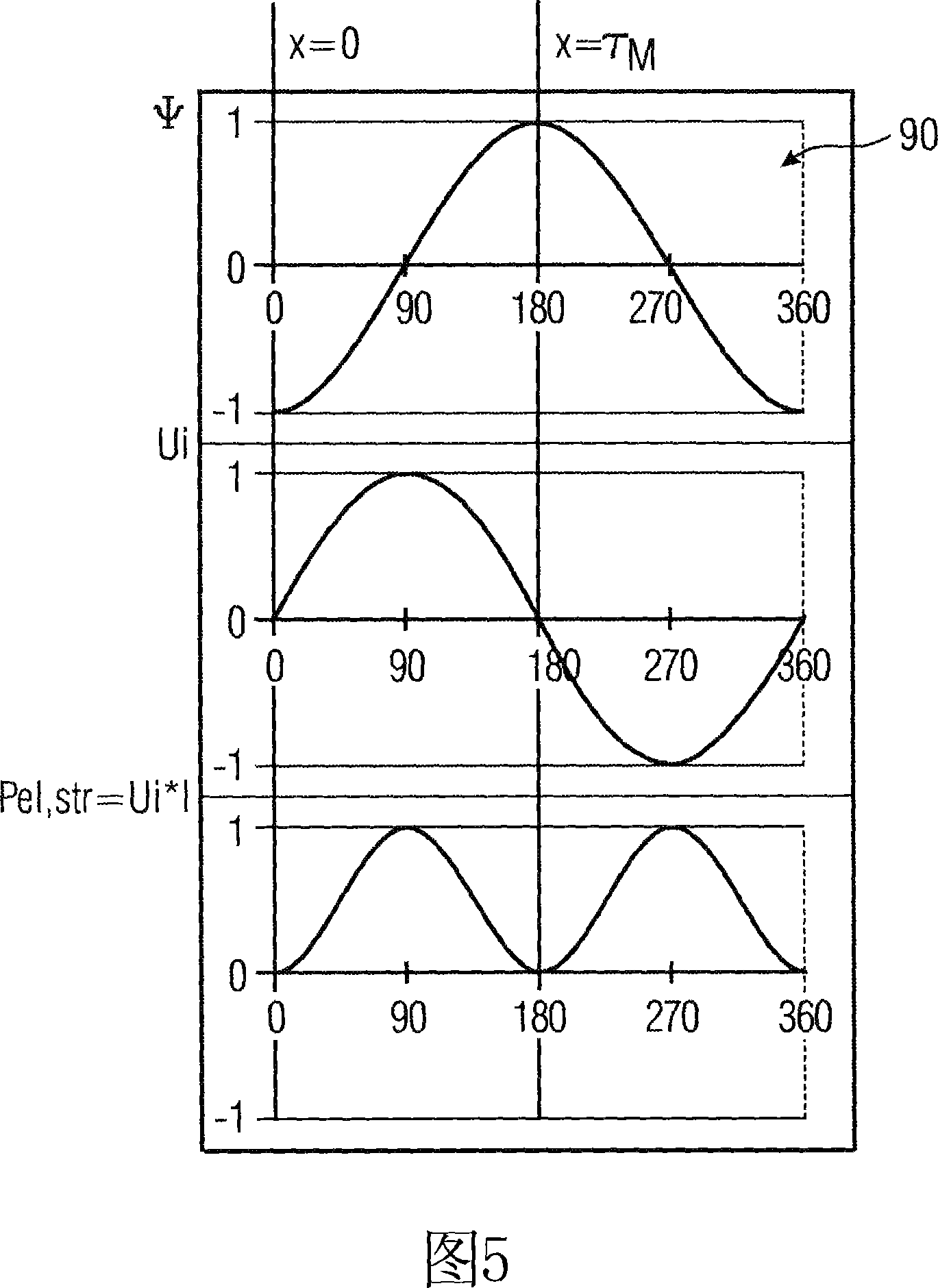

[0081] FIG. 1 shows an electric motor 1 . The electric machine 1 has a primary part 3 and a secondary part 5 . The primary part 3 has a winding 9 and a plurality of permanent magnets 17 . The direction of movement of the primary part 3 is indicated by a double-headed arrow extending in the longitudinal direction 11 . Another double-headed arrow indicates the lateral direction 13 . A third double-headed arrow indicates the normal 15 , wherein the normal relates to an air gap plane 19 not shown in FIG. 1 . However, the air gap plane 19 is shown in FIG. 2 . The arrows point to the side view 7 referring to what is shown in FIGS. 3 and 4 . The electric machine 1 is a linear motor th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com