Synergic extraction agent and method for selectively extracting nickel in acidic nickeliferous solution through synergic extraction agent

An extraction agent and extraction technology, applied in the field of chemical extraction, can solve problems such as complex process, high cost, and incomplete separation of impurities, and achieve the effects of short process, low cost, and low consumption of chemical reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Water phase material liquid: sulfuric acid leaching liquid of waste petroleum hydrogenation catalyst, which contains Ni 2+ 1.836g / L, Fe 3+ 0.179g / L, Al 3+ 33.22g / L, the pH value of the feed liquid is 3.02;

[0034] Organic phase: Prepare three organic phases with different compositions numbered 1, 2, and 3. The diluent in the organic phase is sulfonated kerosene, and the organic phase No. 1 is sulfonated with 0.20mol / L dinonylnaphthalenesulfonic acid Kerosene solution, No. 2 organic phase is sulfonated kerosene solution of 1.0mol / L 4-octyl picolinate, No. 3 organic phase is dinonyl naphthalene sulfonic acid (0.20mol / L) + 4-octyl picolinate (1.0mol / L) of sulfonated kerosene solution.

[0035] Extraction and separation: the above three organic phases are subjected to single-stage extraction under the condition that the ratio of the above three organic phases to the feed liquid (volume ratio of the organic phase to the water phase) is 1 / 1, the extraction equilibrium ti...

Embodiment 2

[0041] The aqueous phase material liquid is laterite nickel ore sulfuric acid heap leaching liquid, which contains Ni 2+ 2.45g / L, Fe 3+ 8.99g / L, Al 3+ 3.03g / L, Mn 2+ 0.41g / L, Mg 2+ 8.20g / L, Ca 2+ 0.23g / L, Cr 3+ 3.87g / L, and the pH value of the feed liquid is 2.03.

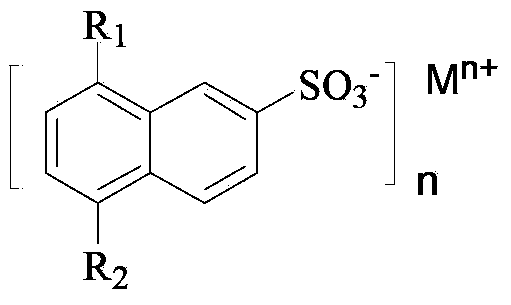

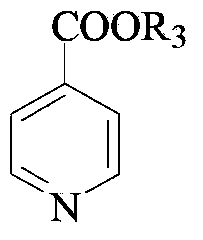

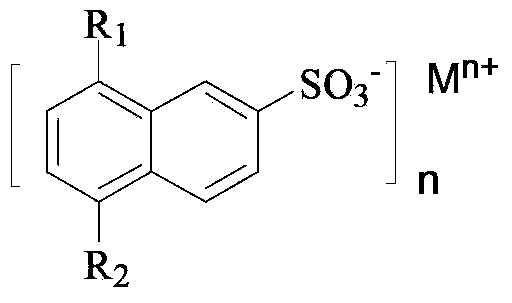

[0042] The organic phase is an aviation kerosene solution of sodium naphthalenesulfonate (0.25mol / L) + pyridine carboxylate (1.0mol / L); wherein the alkyl group R in the pyridine carboxylate 3 is 12 alkyl, R in naphthalenesulfonic acid 1 Alkyl and R 2 The alkyl groups are hexyl and 12-alkyl, respectively.

[0043] The organic phase and the feed liquid are subjected to single-stage extraction, the extraction ratio is 1 / 1, the extraction time is 10 min, and the temperature is 25°C. The experimental results are shown in Table 2.

[0044] Table 2 Extraction experiment results

[0045]

[0046]

[0047] It can be seen from Table 2 that after single-stage extraction, the extraction rate of nickel reaches ...

Embodiment 3

[0049] The aqueous phase feed solution is the same as in Example 1. The organic phase is a solution of No. 260 solvent oil of dinonylnaphthalenesulfonic acid (0.1mol / L) + decyl 4-pyridinecarboxylate (0.6mol / L).

[0050] The organic phase and the aqueous phase feed liquid are subjected to single-stage extraction, the extraction ratio is 3 / 1, the extraction time is 10 min, and the temperature is 5°C. The experimental results are shown in Table 3.

[0051] Table 3 Extraction test results

[0052]

[0053] The results show that during the extraction process, the single-stage extraction rate of nickel can reach more than 96%, iron and aluminum are basically not extracted, and the separation coefficients of Ni / Al and Ni / Fe reach 3500 and 1000 respectively, and the separation effect is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com