Feeding device

A technology of feeding device and drying device, applied in non-progressive dryer, solid separation, dryer and other directions, can solve problems such as unsatisfactory effect, inability to meet drying, no impurities, and reduce the quality of finished products, etc. Achieve good drying and impurity removal effect, shorten production cycle and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

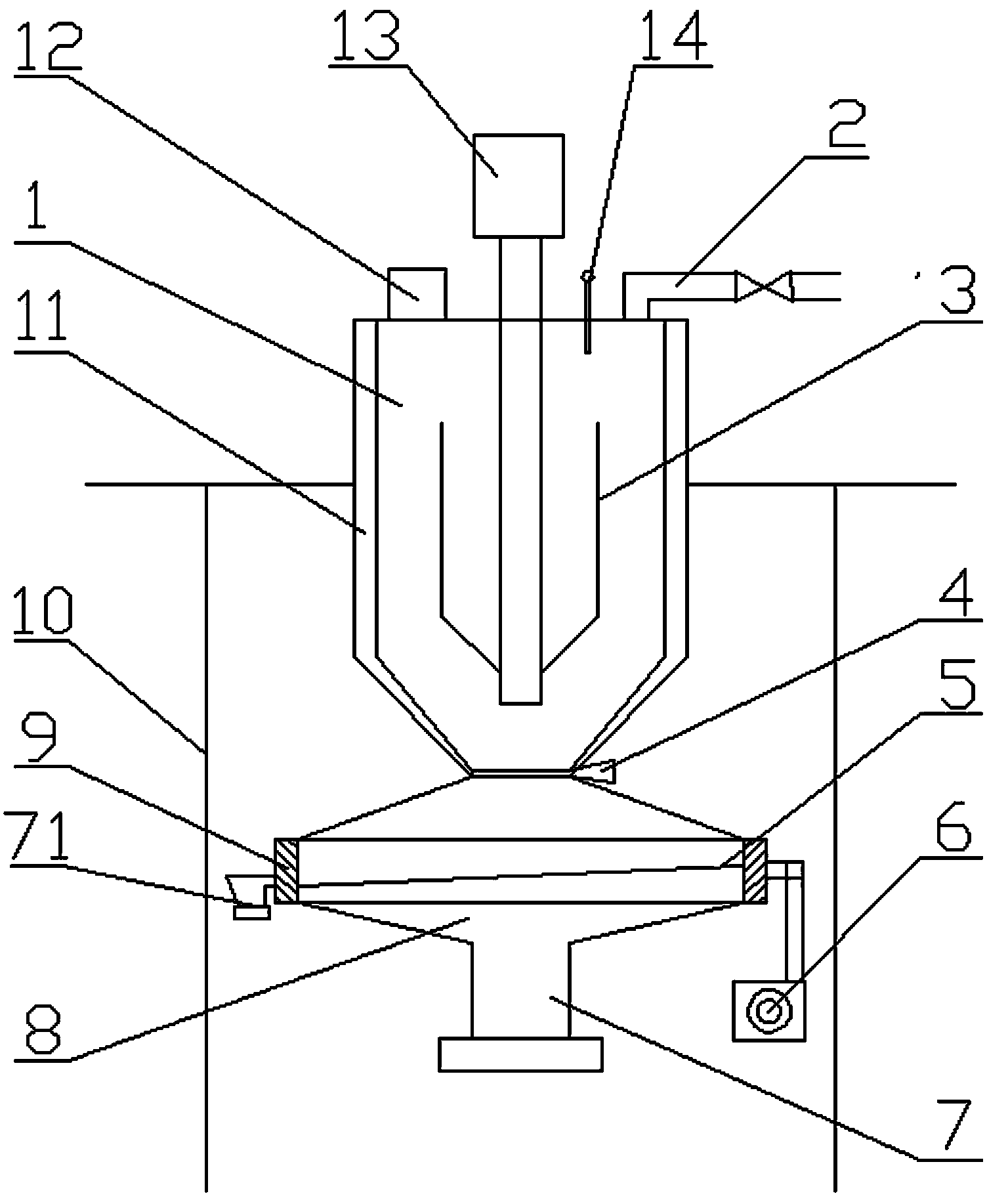

[0015] Such as figure 1 Shown, a kind of feeding device comprises support 10, drying device and screening device, and drying device is fixed on the support 10, and drying device and screening device are movably connected through material control valve 4, and drying device comprises cylinder body 1, and deceleration motor Connected stirring shaft 13 and heating chamber 11, the stirring shaft 13 extends into the interior of the cylinder 1, and is fixed with the stirring paddle 3, the heating chamber 11 is set outside the cylinder 1, and the upper cover of the cylinder 1 is provided with a feeding port 12, humidity Meter 14 and liquid outlet 2; Screening device comprises screening cavity 8, inclined screen cloth 5, vibrating motor 6, flow material port 7 and impurity outlet 71, and screen cloth 5 is fixed on the screening chamber 8 by spring 9, and vibrating The motor 6 is connected, the material flow port 7 is arranged at the bottom of the screening chamber 8, and the impurity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com