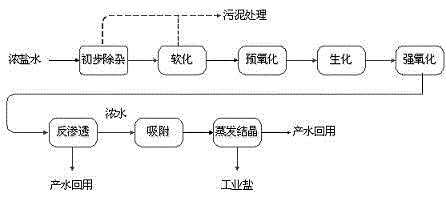

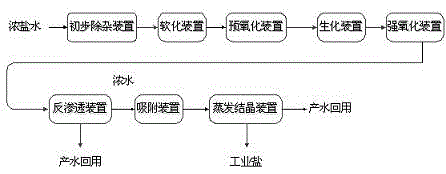

Method and device for realizing zero emission of strong brine

A technology of concentrated brine and zero discharge, applied in water softening, chemical instruments and methods, water pollutants, etc., can solve the problems of high cost and great harm of crystalline miscellaneous salts, and achieve convenient source of medicament, high concentration multiple, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Example 1: Concentrated water discharged from a reclaimed water reuse device in a coal-to-gas plant, treated water volume: 82m 3 / h, COD content in raw water is 500-800mg / L, TOC is 140-200mg / L, TDS is 9000-11000mg / L, total hardness is 400-600mg / L, and total alkalinity is 1800-2000mg / L. The specific processing method is as follows:

[0096] Adjust the pH of the concentrated brine to 9.5, add magnesium oxide 100mg / L, choose PFS as the coagulant, and the dosage is 20mg / L, and use cationic PAM as the coagulant aid, and the dosage is 2mg / L, and carry out chemical precipitation treatment. COD removal rate is 20%, SiO 2 The removal rate is 75%, and the removal rate of heavy metals is 90% on average; the lime-soda ash softening method is used to soften the impurity-removed effluent, and the total hardness removal rate is 90%; the softened effluent is pre-oxidized, and the refractory organic matter is treated with ozone oxidation. Pre-oxidation treatment is carried out, and B / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| working pressure | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com