Iron ore flotation anion/cation collector and preparation method thereof

A technology of anion collector and cation collector, which is applied in flotation, solid separation, etc., can solve the problems of low re-election rate of iron-containing tailings, unstable mineral processing index, low average raw ore grade, etc., and achieve energy saving and environmental protection The effect is obvious, the effect of removing impurities is remarkable, and the effect of increasing iron is outstanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

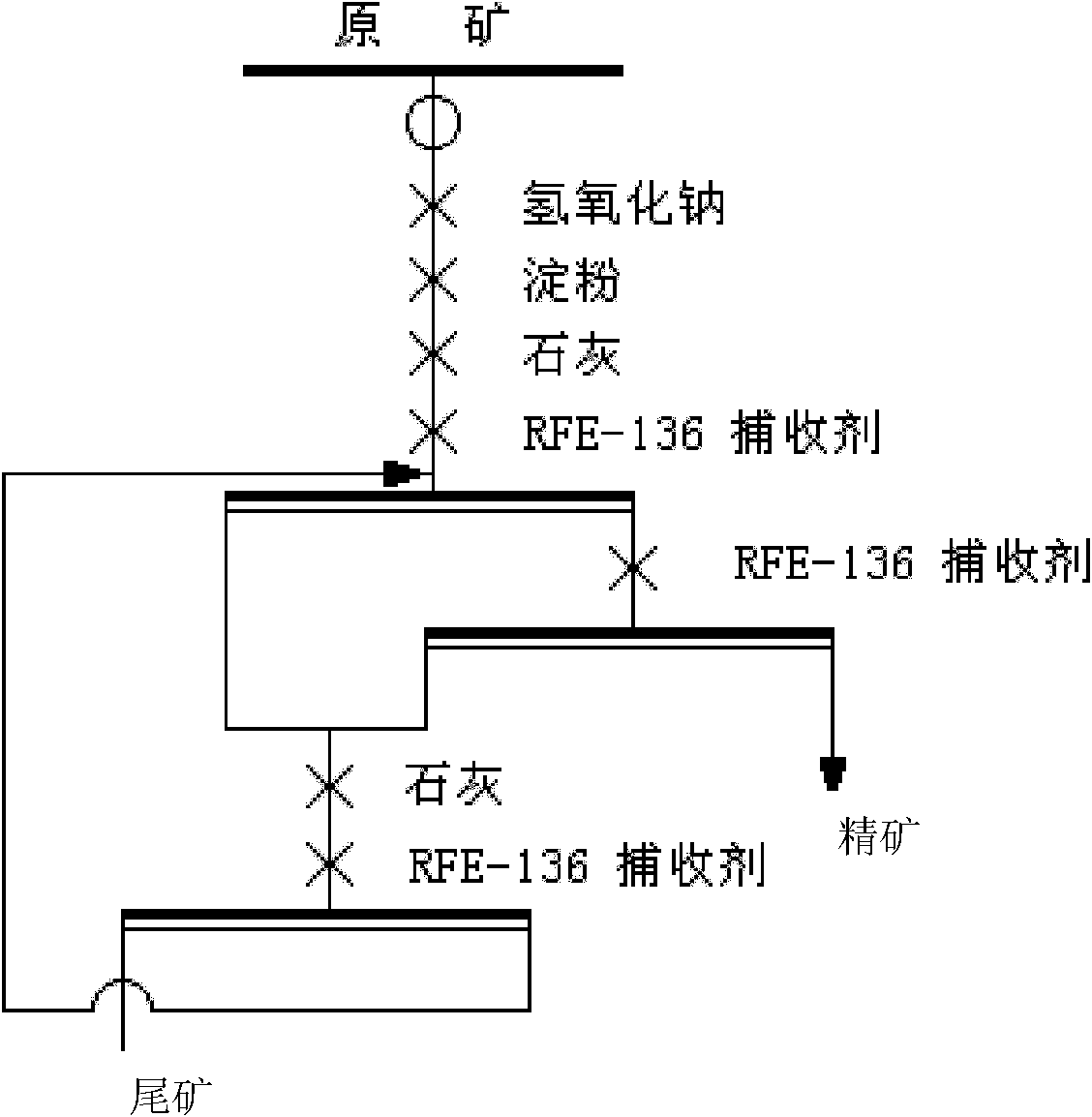

Method used

Image

Examples

Embodiment 1

[0031] A kind of iron ore flotation anion collector of the present invention, this collector is formulated by the component of following quality: dimethyl silicon dichloride 6g, silicon tetrachloride 4g, sulfonated oleic acid 35g , chlorinated nonane 10g, octanol 15g, kerosene 5g, emulsifier OP-102g and water 23g.

[0032] The specific preparation method of the collector in this example is as follows: first synthesize the main agent of sulfonated oleic acid through organic reaction, then mix 35 g of sulfonated oleic acid with the remaining components (i.e. auxiliary agents) of the above-mentioned quality, and stir evenly to prepare Obtain the collector (numbering RFE-136) of microemulsion formulation of the present invention.

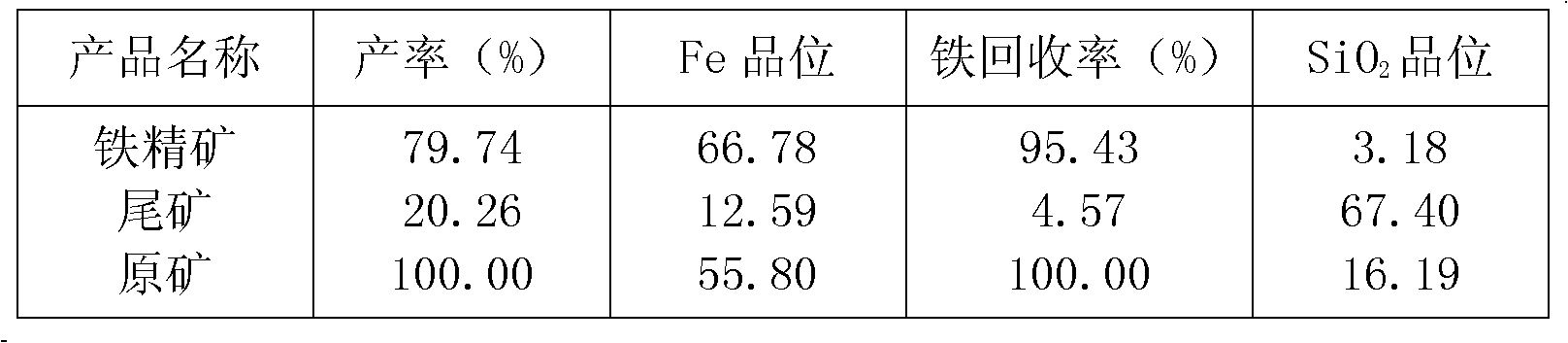

[0033] The application method of the collector in this embodiment is: first dilute the above-mentioned collector with water into a collector solution with a mass concentration of 2%, and then use the collector solution as an anion in a certain foreign i...

Embodiment 2

[0040] An anion collector for iron ore flotation of the present invention, the collector is mainly prepared from the following components: methyl silicon dichloride 5g, sulfated C3-C22 straight chain and / or branched chain mixed Fatty acid 32g, chlorododecane 20g, hydroxylated kerosene 13g, diesel oil 5g, emulsifier Tween-80 3g and water 22g.

[0041] The specific preparation method of the collector in this example is as follows: first synthesize the main agent of sulfated C3-C22 linear and / or branched-chain mixed fatty acids through organic reaction, and then make the sulfated C3-C22 straight-chain and / or branched-chain mixed fatty acids 32g is mixed with the remaining components of the above-mentioned quality (ie adjuvant), and stirred evenly to obtain the collector of the microemulsion type of the present invention. The preparation process produces no waste gas and waste residue, and only produces a small amount of waste water, which can be discharged up to standard through ...

Embodiment 3

[0047] An anion collector for iron ore flotation of the present invention, the collector is mainly prepared from the following components: 3g of dimethyl polysilicone, 30g of sulfonated soybean oil, 20g of tetradecane chloride , tetradecyl alcohol 15g, diesel oil 7g, emulsifier OP-105g and water 20g.

[0048] The specific preparation method of the collector in this example is as follows: first synthesize the main agent of sulfonated soy oil through organic reaction, then mix 30 g of sulfonated soy acid with the remaining components (i.e. adjuvant) of the above-mentioned quality, and stir evenly to prepare Obtain the collector of microemulsion formulation of the present invention.

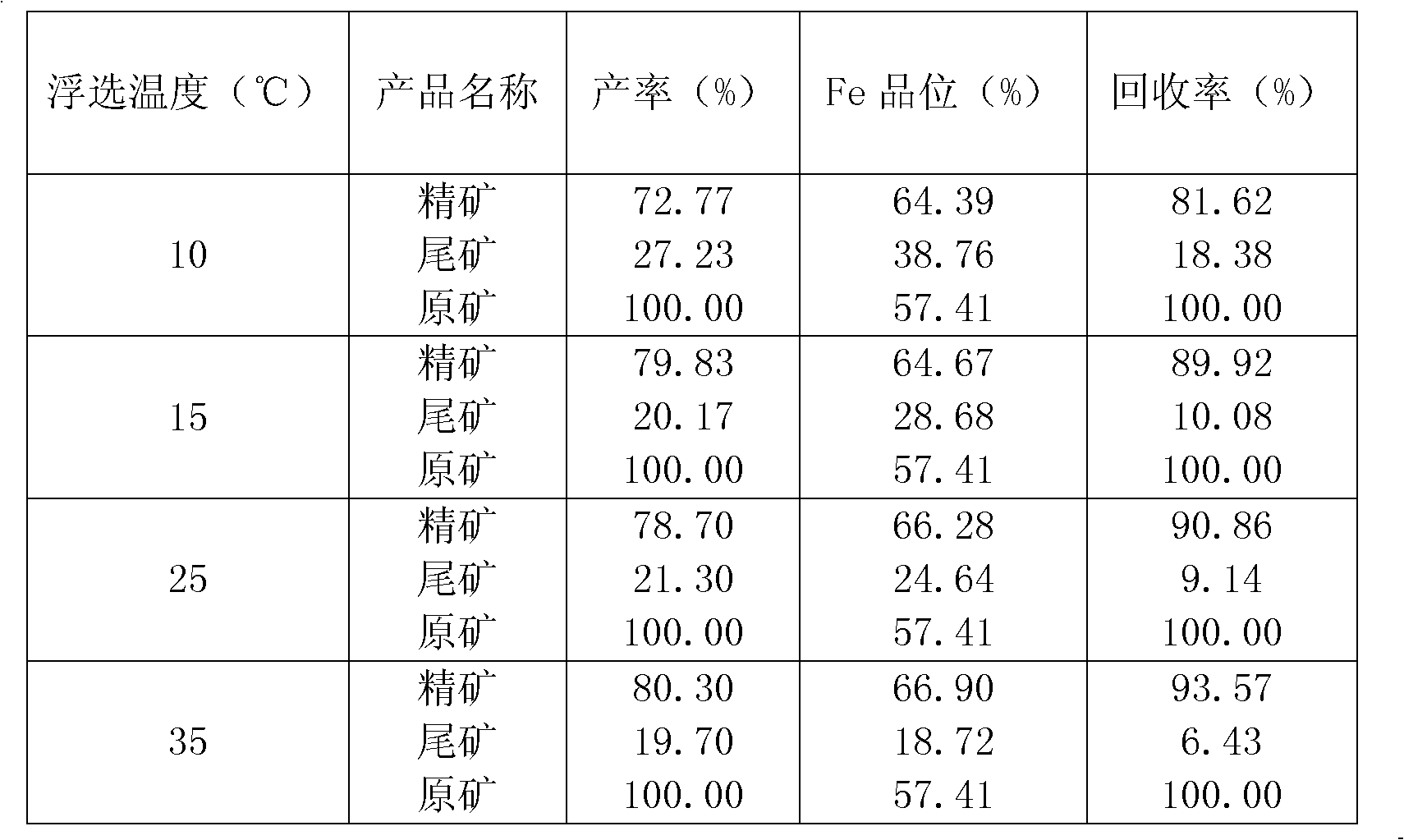

[0049] The application method of the collector in this example is as follows: first dilute the above-mentioned collector with water into a collector solution with a mass concentration of 2%, and then use the collector solution as tailings after a domestic copper smelting In the anion reverse flotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com