Tea Static Cleaner

An electrostatic and tea technology, applied in the field of tea electrostatic impurity removal machine, can solve the problems of high production cost of impurity removal equipment, difficult to remove tea sundries, and lower tea quality, etc., and achieves a simple structure, saves production costs, and improves work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

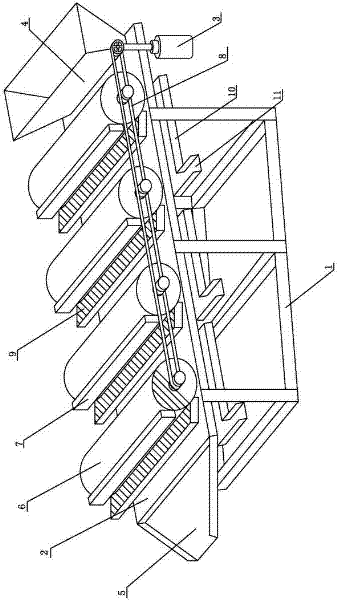

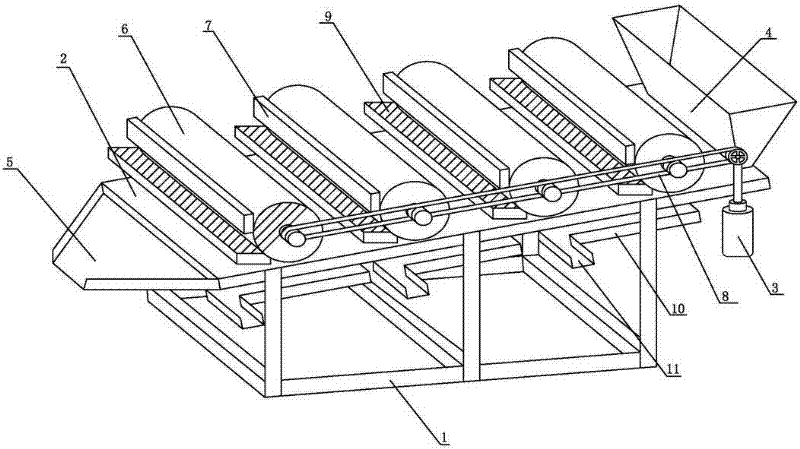

[0018] Embodiment 1: A kind of tea electrostatic impurity remover, comprises frame 1, feeding plate, motor 3 and the feed inlet 4 and discharge port 5 that are installed on the two ends of feed plate, and feed plate is installed on the frame 1, and motor 3 Installed on one end of the frame 1, four pairs of felt strips 7 and horizontally placed engineering plastic rollers 6 are arranged above the feeding plate. The distance between the engineering plastic rollers 6 and the feeding plate is 38 mm. The two contacts, the motor 3 is connected with the engineering plastic roller 6 through the transmission belt 8, and drives the engineering plastic roller 6 to rotate. When the engineering plastic roller 6 rotates, it rubs against the felt strip 7, and static electricity is generated on the surface of the engineering plastic roller 6. The light and small sundries mixed in the tea are adsorbed on the surface of the engineering plastic roller 6 . A slant plate 9 is installed below each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com