Process for preparing fine algae cultivation coupling biological diesel oil refining

A technology for biodiesel and microalgae cultivation, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high raw material costs and high prices, and achieve the goals of reducing procurement costs, avoiding damage, and saving procurement costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

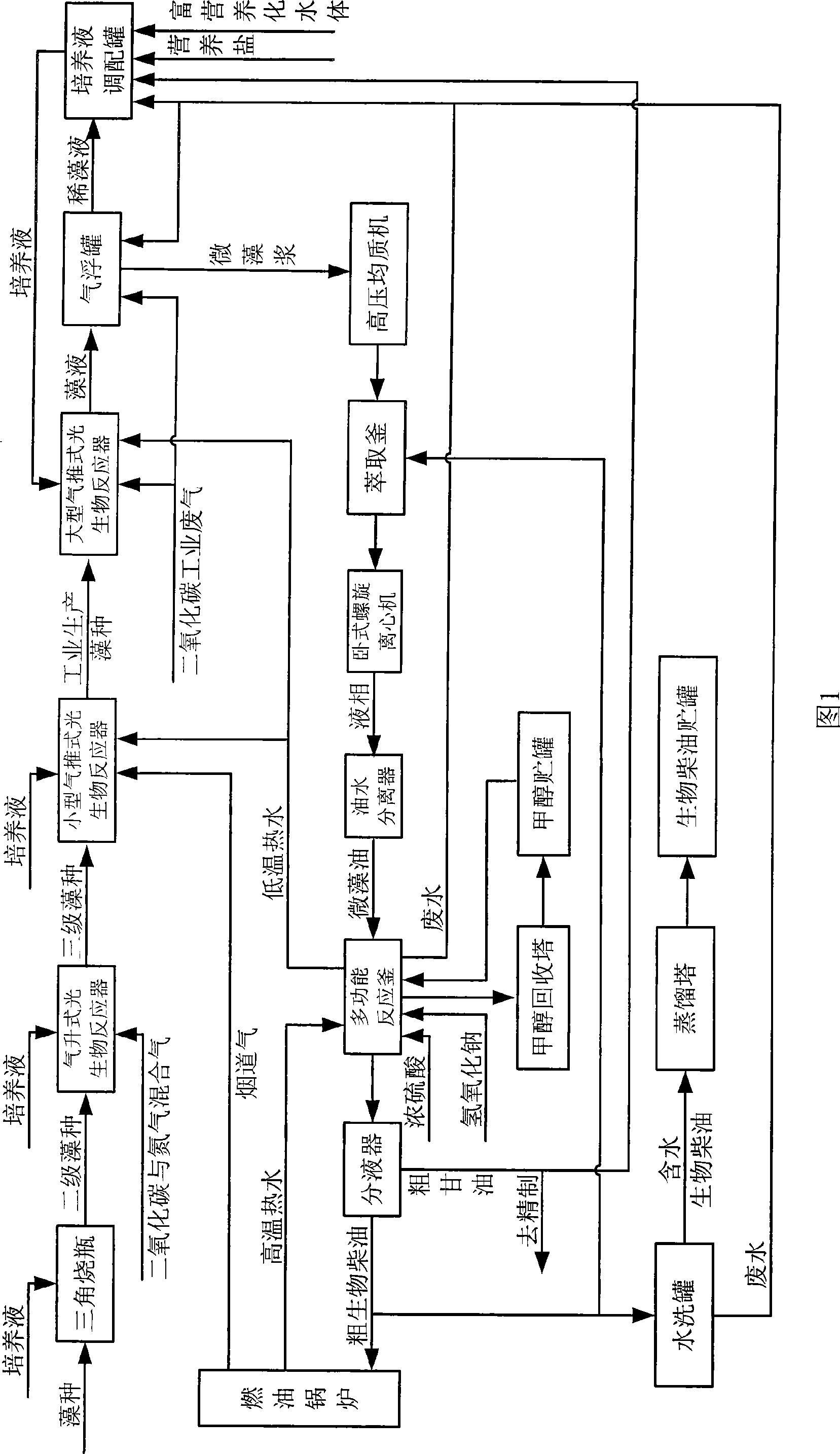

[0020] The present invention will be further described below in conjunction with the accompanying drawings and the embodiments given in the accompanying drawings. The manufacturing techniques of the present invention are easily implemented by those skilled in the art.

[0021]Referring to Fig. 1, the key equipment for microalgae cultivation coupled with biodiesel refining adopts the air-pushed photobioreactor (air-pushed photobioreactor. Chinese invention patent, application number: 200810039168.8; Microalgae industrial production device and method for producing microalgae. Chinese invention patent, application number: 200810038075.3), biodiesel refining equipment (multifunctional reactor for biodiesel production and its operation method. Chinese invention patent, application number: 200810039167.3), wherein, the manufacturing method of the small-scale air-push photobioreactor is "Air-push photobioreactor. Chinese invention patent, application number: 200810039168.8" previousl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com