Production method for extracting sweet tea glucoside from sweet tea leaves

A production method and rubusoside technology are applied in the field of rubusoside extraction, which can solve the problems that the market promotion level of industrialized large-scale production machines cannot be really reached, that the industrial production of rubusoside has not been reported, and that the application of rubusoside is limited. Separation, reduce solvent consumption, control foaming and run-off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

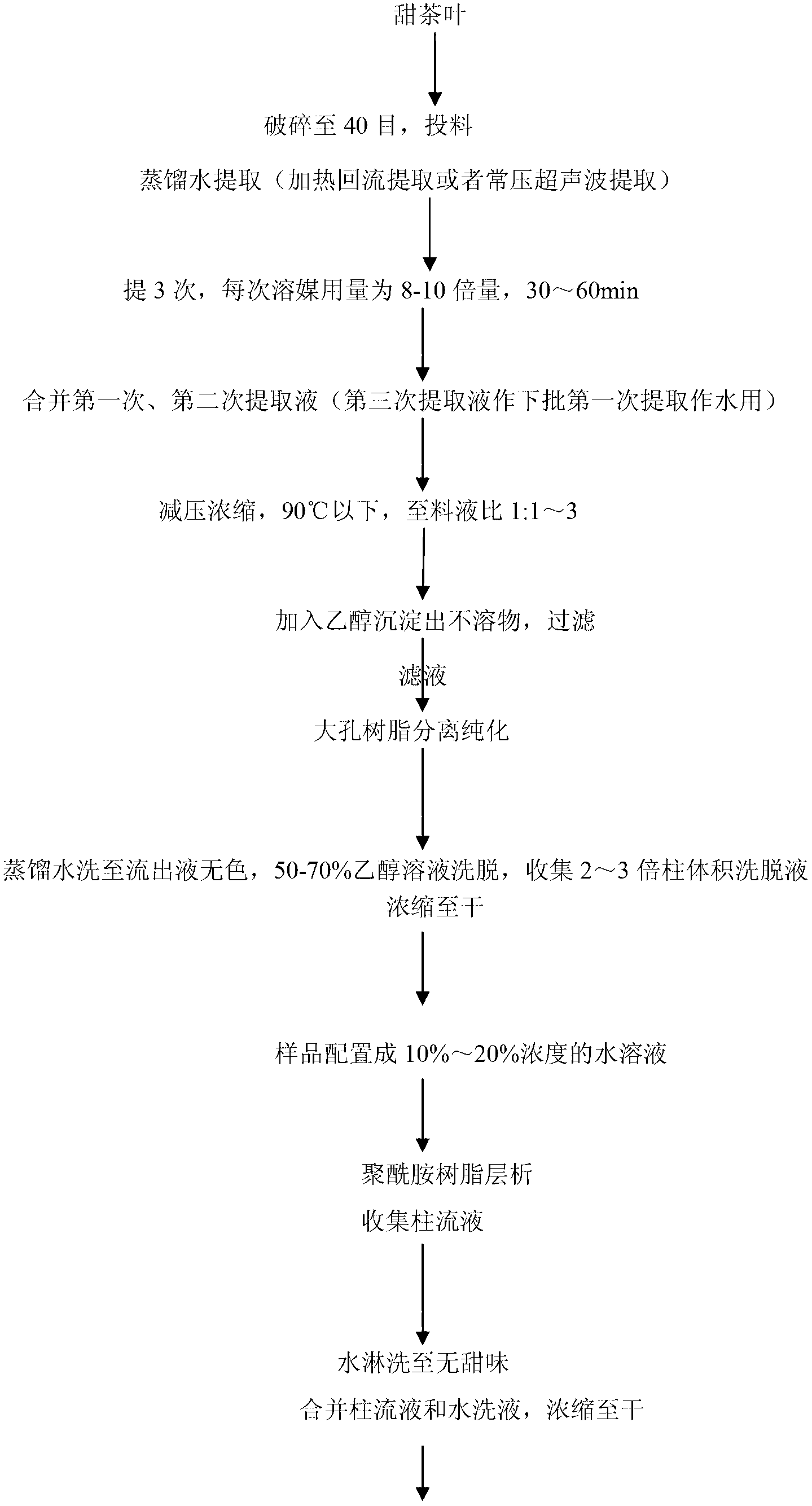

Method used

Image

Examples

Embodiment 1

[0033] Take 500Kg of sweet tea leaves (the detected content is 5.2%), crush them and pass through a 40-mesh sieve, put them into the extraction tank, add 5000L of distilled water, heat to 80°C, reflux for 60min, suction filter while hot, add 4000L to the medicinal residues The distilled water is used for the second and third extractions, refluxed for 30 min / time under the same conditions, the first and second extractions are combined and concentrated to 500L, and the third extraction is used as water for the first extraction of the next batch. Add 350L ethanol to the concentrated solution to precipitate insoluble matter, filter, add the filtrate to the pretreated 50KgD101 resin column, the flow rate is 5BV / h, after the column is loaded, wash with purified water until the effluent is colorless, and finally elute with 70% ethanol , flow rate 1BV / h, collect 150L of the eluate, and concentrate to dryness. The sample was configured into an aqueous solution with a concentration of 2...

Embodiment 2

[0035]Take 500Kg of sweet tea leaves (the detected content is 5.4%), crush them to 40 mesh, put them into an ultrasonic extraction tank, add 5000L distilled water, ultrasonic output power 800W, ultrasonically extract at 80°C for 6min, filter, add 4000L distilled water to the medicinal residues again for extraction For the second and third extractions, after 6 minutes of extraction under the same conditions, the first and second extractions were combined and concentrated to 500L, and the third extraction was used as the next batch for the first water treatment. Add 350L ethanol to the concentrated solution to precipitate insoluble matter, filter, add the filtrate to the pretreated 50KgD101 resin column, the flow rate is 5BV / h, after the column is loaded, wash with purified water until the effluent is colorless, and finally elute with 70% ethanol , flow rate 1BV / h, collect 150L of the eluate, and concentrate to dryness. The sample was configured into an aqueous solution with a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com