Silicon rubber with high refractive index and high transparency for optical encapsulation and preparation method thereof

A technology of high refractive index and silicone rubber, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as unusable, no silicone rubber for packaging, no adhesiveness of LED packaging materials, storage stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

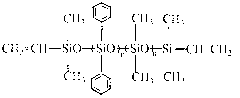

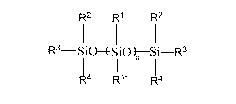

[0050] (1) Preparation of component A phenyl vinyl silicone resin (PhSiO 3 / 2 ) 0.55 (Ph 2 SiO 2 / 2 ) 0.02 (Me 3 SiO 1 / 2 ) 0.22 (ViMe 2 SiO 1 / 2 ) 0.21 , its vinyl content is 5wt%, and the refractive index is 1.518, and method is as follows: Accurately weigh hexamethyldisiloxane 81.8, diphenyldiethoxysilane 25g, phenyltriethoxysilane 606g, toluene 500g Add the mixture of trifluoromethanesulfonic acid and 0.6g into a 2L flask, stir at 25°C, slowly add distilled water dropwise, the amount of water added dropwise is 45.5g, after the dropwise addition, slowly raise the temperature to 50°C, and continue the reaction for 3 Hour. Then, 89.7 g of 1,3-divinyl-1,1,3,3-tetramethyldisiloxane was added. The temperature was raised to 60° C. for 3 hours. Then the heterogeneous system obtained by the reaction is layered with a separatory funnel, the solvent and the resin part are taken, and anhydrous calcium chloride is added. The reaction was continued at 100°C for 2 hours. After ...

Embodiment 2

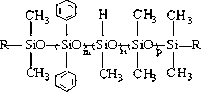

[0054] (1) Preparation of component A phenyl vinyl silicone resin (PhSiO 3 / 2 ) 0.55 (Ph 2 SiO 2 / 2 ) 0.02 (Me 3 SiO 1 / 2 ) 0.33 (ViMe 2 SiO 1 / 2 ) 0.1 , its vinyl content is 2.5wt%, and its refractive index is 1.512. The method is as follows: accurately weigh hexamethyldisiloxane 122.7, diphenyldiethoxysilane 25g, phenyltriethoxysilane 606g, toluene Add the mixture of 500g and 0.6g of trifluoromethanesulfonic acid into a 2L flask, stir at 25°C, slowly add distilled water dropwise, the amount of water added is 45.5g, after the dropwise addition, slowly raise the temperature to 50°C, and continue the reaction 3 hours. Then, 42.7 g of 1,3-divinyl-1,1,3,3-tetramethyldisiloxane was added. The temperature was raised to 60° C. for 3 hours. Then the heterogeneous system obtained by the reaction is layered with a separatory funnel, the solvent and the resin part are taken, and anhydrous calcium chloride is added. The reaction was continued at 100°C for 2 hours. After the rea...

Embodiment 3

[0058] Get A component (PhSiO2) gained in embodiment 1 3 / 2 ) 0.55 (Ph 2 SiO 2 / 2 ) 0.02 (Me 3 SiO 1 / 2 ) 0.22 (ViMe 2 SiO 1 / 2 ) 0.21 14.16g, gained A component (PhSiO 3 / 2 ) 0.55 (Ph 2 SiO 2 / 2 ) 0.02 (Me 3 SiO 1 / 2 ) 0.33 (ViMe 2 SiO 1 / 2 ) 0.1 9.44g, gained B component Vi(Me) in embodiment 2 2 SiO(Ph 2 SiO 2 / 2 ) 38 (Me 2 SiO 2 / 2 ) 84 Si(Me) 2 Vi 9.44g, D component platinum complex catalyst 0.03g, blend to get the first part; Get A group (PhSiO 3 / 2 ) 0.55 (Ph 2 SiO 2 / 2 ) 0.02 (Me 3 SiO 1 / 2 ) 0.22 (ViMe 2 SiO 1 / 2 ) 0.21 6.84g, gained A component (PhSiO 3 / 2 ) 0.55 (Ph 2 SiO 2 / 2 ) 0.02 (Me 3 SiO 1 / 2 ) 0.33 (ViMe 2 SiO 1 / 2 ) 0.1 4.56g, gained B component Vi(Me) in embodiment 2 2 SiO(Ph 2 SiO 2 / 2 ) 38 (Me 2 SiO 2 / 2 ) 84 Si(Me) 2 Vi 4.56g, gained C component H(Me) in embodiment 1 2 SiO(Ph 2 SiO 2 / 2 ) 11 (Me 2 SiO 2 / 2 ) 22 (MeHSiO 2 / 2 ) 21 Si(Me) 2 H 16.1g, E component 1-acetylene-1-cyclohexanol 0.02g, F component epox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com