Catalyst for catalytic oxidation of ozone, and preparation method and application thereof

An ozone catalytic oxidation and catalyst technology, applied in the field of water treatment, can solve the problems of poor stability, complex catalyst process, low treatment efficiency, etc., and achieve the effects of stable catalytic performance, easy large-scale industrial production, and stable catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention discloses a preparation method of an ozone catalytic oxidation catalyst, comprising the following steps:

[0029] a. γ-Al with a diameter of dmm 2 o 3 Wash with deionized water, dry in an oven at 105°C for 1 hour, and then 1 ℃ in a muffle furnace for 5 hours, take it out and cool to room temperature to obtain pretreated γ-Al 2 o 3 ;

[0030] b. Pretreat γ-Al 2 o 3 Immerse in 1mol / L NaOH aqueous solution for 4 hours, take it out by filtration, wash with distilled water until the pH does not change, dry in an oven at 105°C, and then immerse in a mixed solution of ferric nitrate and copper nitrate. The amount ratio of substances is n 1 , the concentration of the mixed solution of ferric nitrate and copper nitrate is C 1 mol / L, pretreatment γ-Al 2 o 3 The ratio to the mixed solution is n 2 , the immersion time is T, and the catalyst precursor is obtained;

[0031] c. After drying the catalyst precursor in an oven at 105°C for 1 hour, at t 2 Roast ...

Embodiment 1-5

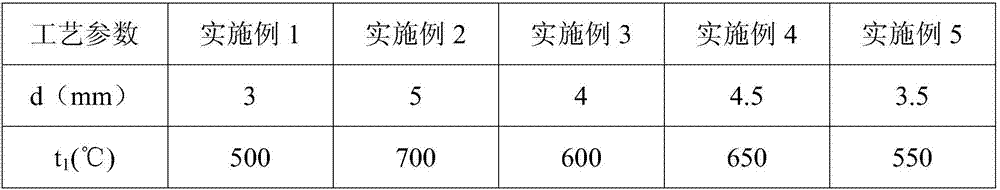

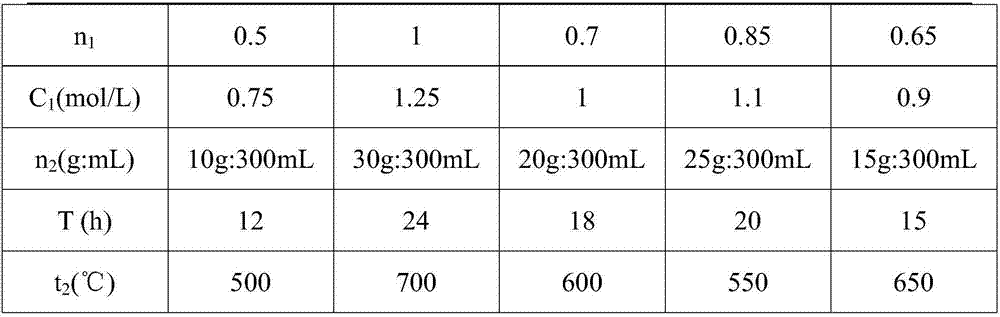

[0033] According to the preparation method of the above-mentioned ozone catalytic oxidation catalyst, each step process parameter of embodiment 1-5 is as shown in table 1 below:

[0034] Table 1 process parameter list

[0035]

[0036]

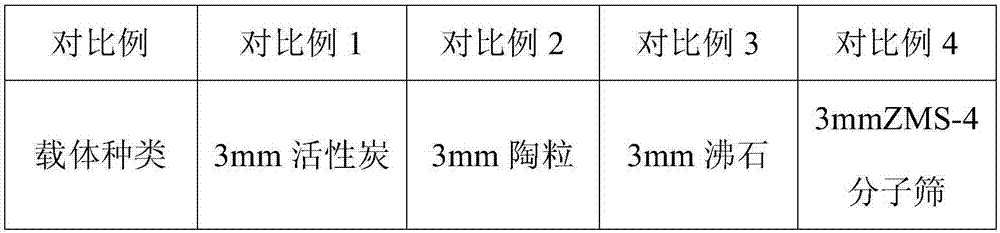

[0037] In Comparative Examples 1-14, the effects of carrier type, mixed solution type and concentration, and calcination temperature were studied. The process parameter values of various variables are shown in Table 2-4 below. The preparation method and other process parameters are the same as in Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com