Process for recovering sodium isooctoate from pharmaceutical waste liquor

A technology of sodium isooctanoate and isooctanoic acid, which is applied in the direction of carboxylate preparation, carboxylate preparation, carboxylate preparation, etc., can solve the problems of environmental pollution, production cost increase, consumption of sodium isooctanoate, etc., and achieve simple operation, Low cost, cost and time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

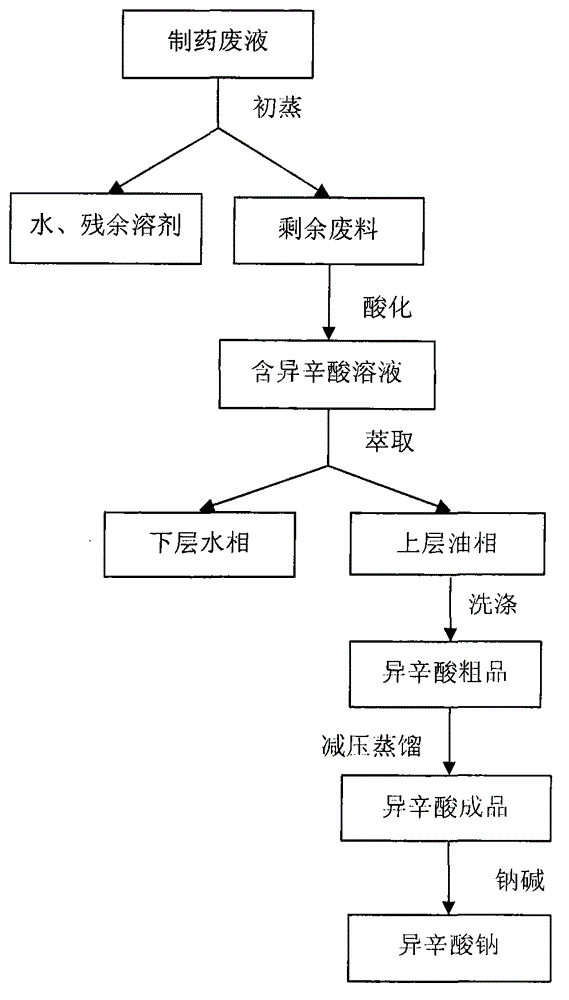

Method used

Image

Examples

Embodiment 1

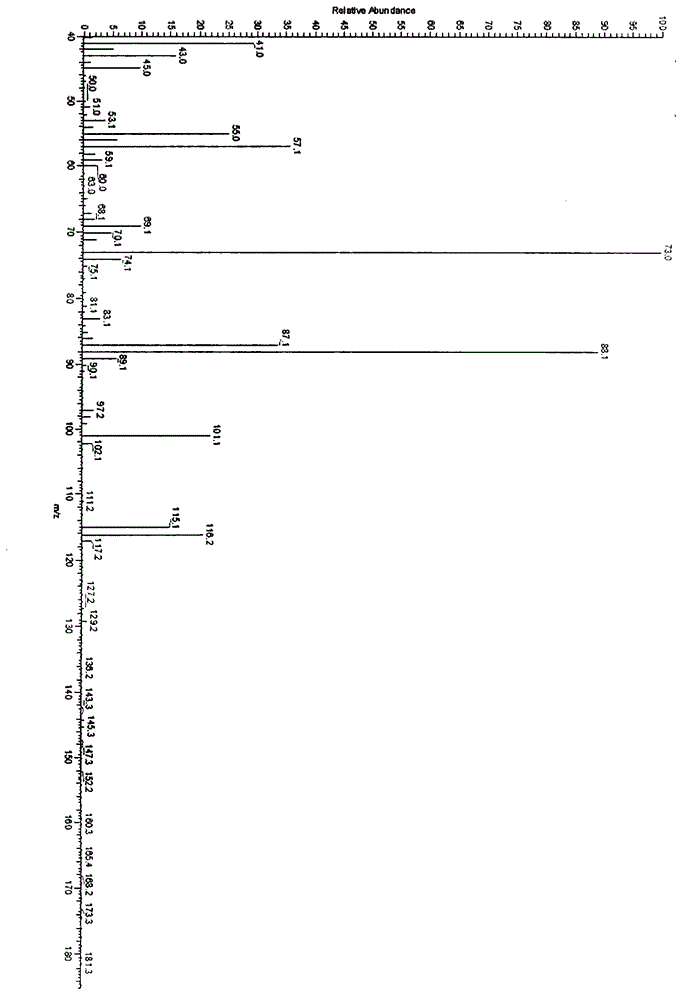

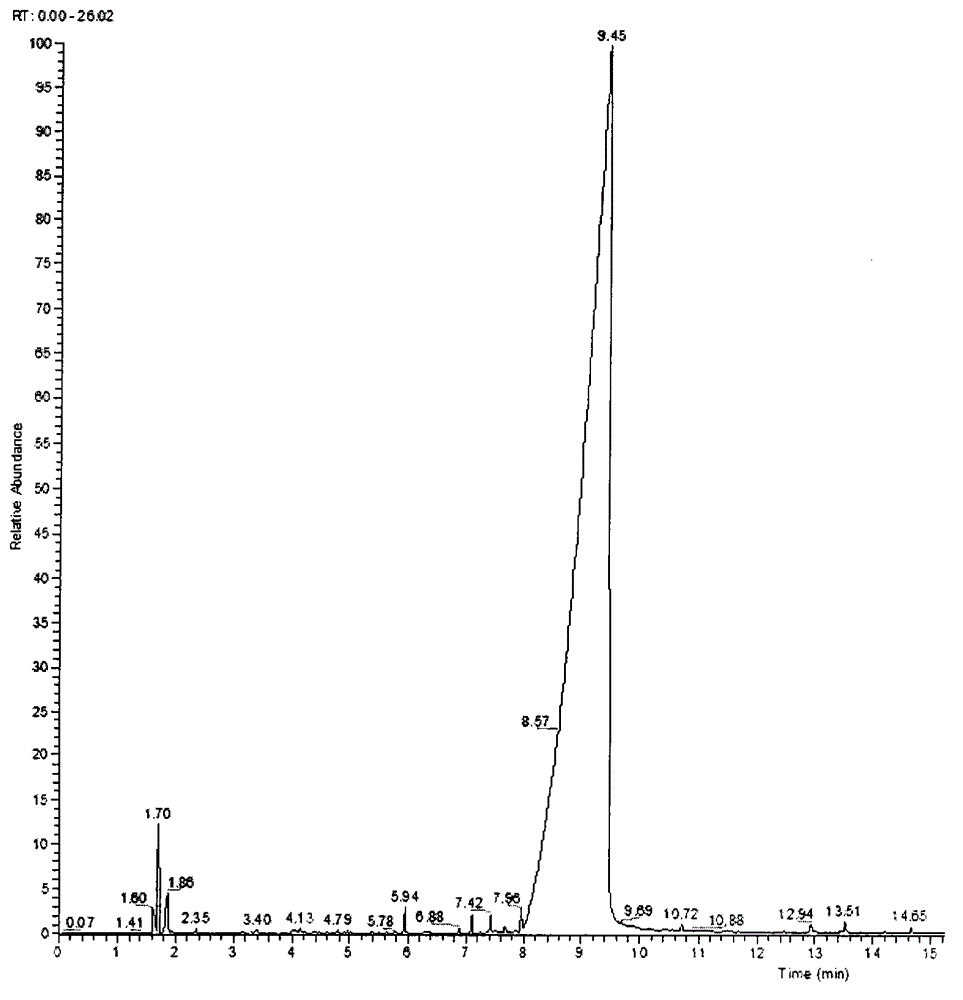

[0023] Take 200g of pharmaceutical waste liquid and place it in a 500ml three-necked flask, distill off the water and residual organic solvent in the waste liquid at 100°C to obtain 62.8g of semi-solid waste, put the semi-solid waste in a 500ml beaker, and add 10ml of concentration dropwise It is a 95% concentrated sulfuric acid solution, stirred for 10 minutes, after the isooctanoic acid salt and sulfuric acid are fully reacted, add 200ml of distilled water, stir for 10 minutes, after standing for stratification, take the upper oil phase, shake and wash twice with 200ml of distilled water, and obtain the crude product of isooctanoic acid 40.0ml, put it in a three-necked flask, distill under reduced pressure, the distillation pressure is 20kPa, and the distillate at a temperature of 170-180°C is collected to obtain 22.3g of isooctanoic acid product, and the purity of isooctanoic acid is detected by gas chromatography; Isooctanoic acid essence reacts with sodium carbonate to gen...

Embodiment 2

[0036] Get 200g pharmaceutical waste liquid and place in the 500ml there-necked flask, distill off water and residual organic solvent in the waste liquid, obtain 60g semi-solid waste material, waste material is placed in the 500ml beaker, dropwise the formic acid solution that 20ml concentration is 88%, Stir for 10 minutes, add 200ml of distilled water after fully reacting isooctanoic acid with formic acid, stir for 10 minutes, after standing for stratification, take the upper oil phase, wash twice with 200ml of distilled water to obtain 41.8ml of crude isooctanoic acid, put it in a 100ml three-port In the flask, distill under reduced pressure, the distillation pressure is 20kPa, and the distillate collected at a temperature of 170 to 180° C. is obtained to obtain 23.4 g of isooctanoic acid refined product, and the purity of isooctanoic acid is detected by gas chromatography; Sodium octanoate, calculate the yield.

[0037] The method for detecting the purity of isooctanoic aci...

Embodiment 3

[0040] Get 200g of pharmaceutical waste liquid and place it in a 500ml three-necked flask, distill off the water and residual organic solvent contained in the waste liquid to obtain 65.1g of semi-solid waste, place the waste in a 500ml beaker, and add 25ml of 38% hydrochloric acid dropwise solution, stirred for 10 minutes, after fully reacting isooctanoate with hydrochloric acid, add 100ml of distilled water and 100ml of ether, stir for 10min, after standing for stratification, take the upper oil phase and shake and wash twice with 200ml of distilled water to obtain 140ml of crude isooctanoic acid. Put the caprylic acid crude product in a three-necked flask, distill under reduced pressure, the distillation pressure is 20kPa, and collect the distillate at a temperature of 170-180°C to obtain 23.0g of iso-octanoic acid fine product. The purity of iso-octanoic acid is detected by gas chromatography; Sodium carbonate reacts to generate sodium isooctanoate, and the yield is calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com