Antibiotic tablet mixing and forming device

A hybrid molding and antibiotic technology, which is used in devices, mixers, material molding presses, etc. to make medicines into special physical or taking forms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

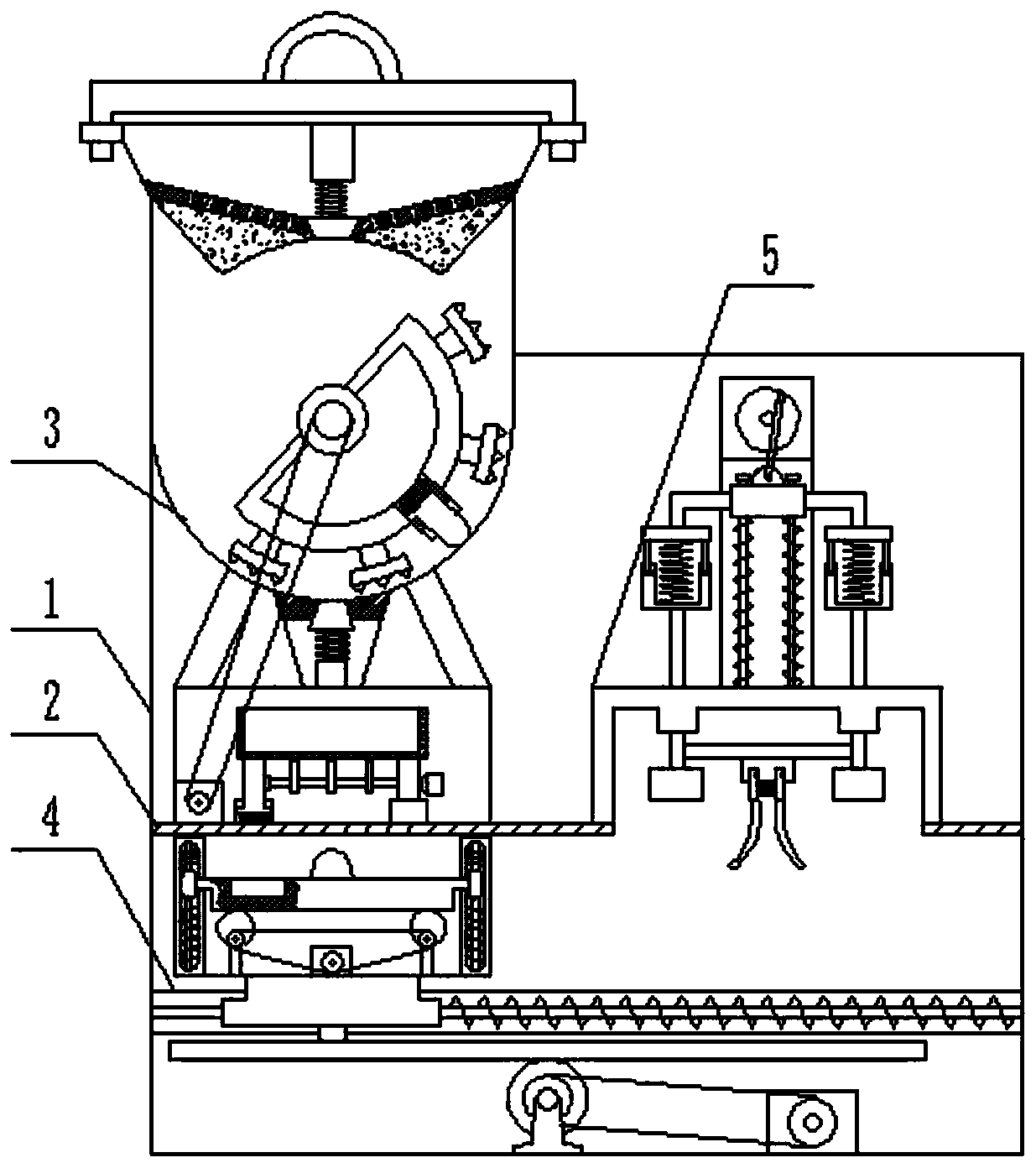

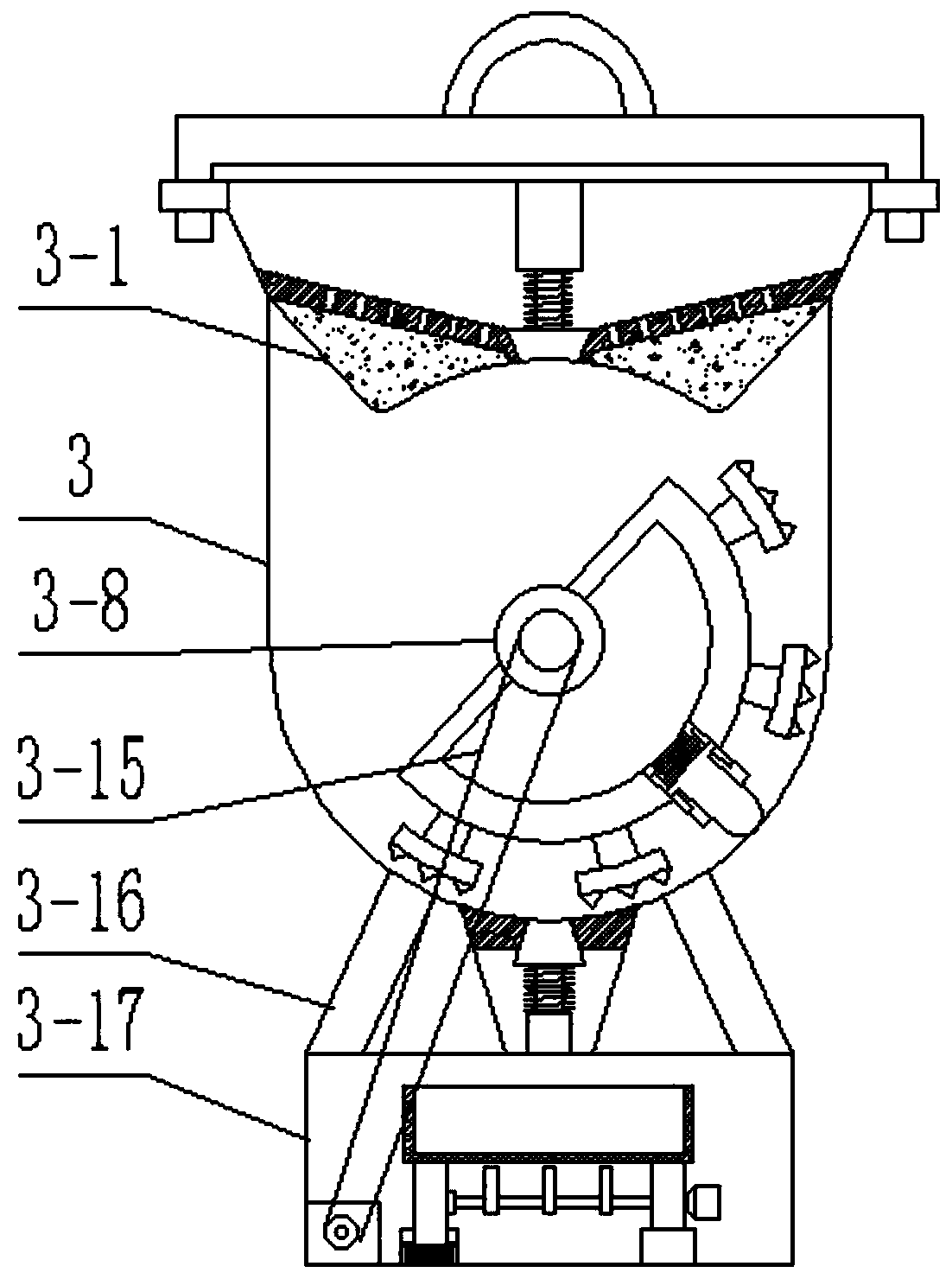

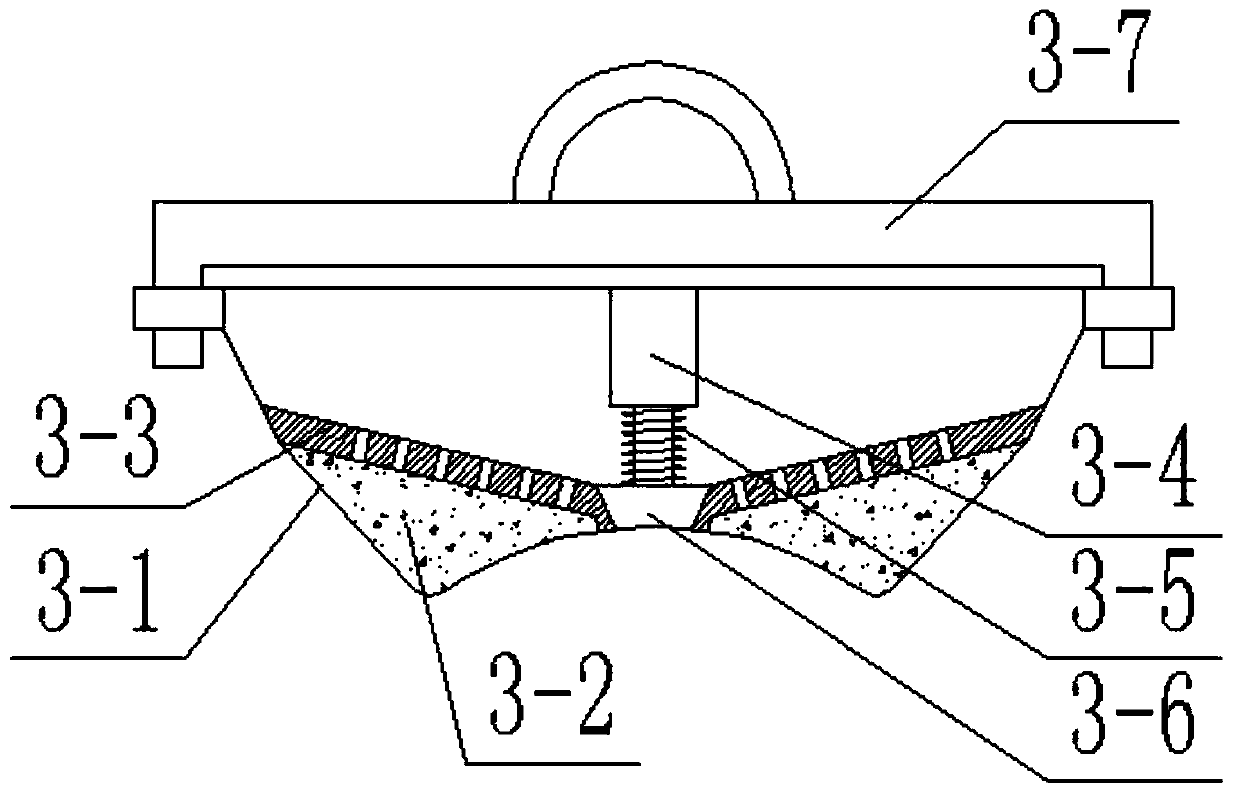

[0035] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17 illustrate this embodiment, the present invention relates to an antibiotic-related device, more specifically a An antibiotic tablet mixing and molding device. It includes shell 1, partition 2, mixing box 3, forming control box 4, and stamping box 5, which can solve the needs of antibiotic production and production by mixing and then packaging and forming, and ensure that the raw materials are dry during processing. The existing antibiotic production uses Manual mixing, subpackaging and molding, direct contact with antibiotic raw materials by manual operation will lead to the problem of contamination of raw materials, and the problem that the drying of raw materials cannot be guaranteed, and it can also solve the problem that operators are directly exposed to antibiotic raw materials for a long time and will cause harm to the body. .

[0036] The inside of the casing 1 is welded with a pa...

specific Embodiment approach 3

[0039] Combine below figure 1 , 2 . The upper end of box 4 is provided with control box gear base 4-1, control box gear 4-2, control box belt 4-3, control box motor 4-4, rack 4-5, control box limit post 4-6 , control box spring 4-7, loading plate base 4-8, loading plate limit column 4-9, loading plate spring 4-10, loading plate 4-11, diversion limiting block 4-12 , Loading tank 4-13, loading plate slider 4-14, eccentric wheel support column 4-15, eccentric wheel 4-16, loading plate base motor 4-17, loading plate belt 4-18, loading Material plate base slide table 4-19, the inside of forming control box 4 is welded with control box gear base 4-1, the upper end of control box gear base 4-1 rotates with control box gear 4-2, control box gear 4 The upper end of -2 is provided with a control box belt 4-3, and the inside of the forming control box 4 is fixed with a control box motor 4-4, and the upper end of the control box motor 4-4 is provided with a control box belt 4-3, and th...

specific Embodiment approach 4

[0041] Combine below figure 1 , 2 . The upper end of 5 is provided with punching post 5-1, punching block 5-2, secondary punching sliding base 5-3, secondary punching sliding block 5-4, secondary punching spring 5-5, power box 5-6, Power box limit column 5-7, power box spring 5-8, power box slider 5-9, slider support arm 5-10, power box motor 5-11, power box articulated arm 5-12, linkage rod 5 -13, rubber scraper base 5-14, rubber scraper 5-15, rubber scraper spring 5-16, the upper end of stamping box 5 slides with stamping column 5-1, and the lower end of stamping column 5-1 is welded with stamping Block 5-2, the upper end of the stamping column 5-1 is welded with a secondary punching and sliding base 5-3, and the internal sliding of the secondary punching and sliding base 5-3 has a secondary punching and sliding block 5-4, and the secondary punching and sliding The upper end of the base 5-3 is fixed with a secondary stamping spring 5-5, the upper end of the stamping box 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com