Treatment method of antibiotic production wastewater

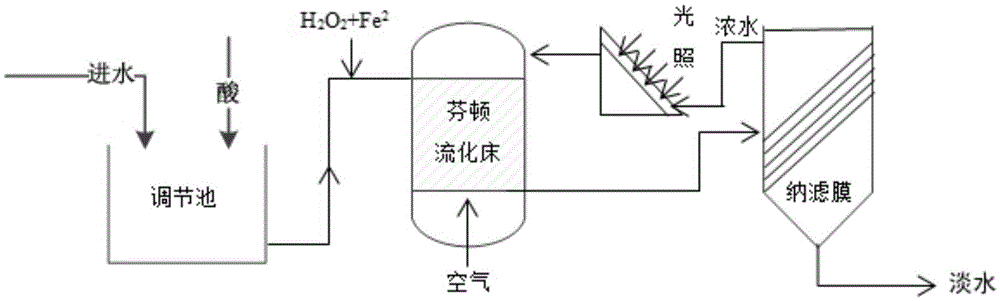

A technology for producing wastewater and a treatment method, which is applied in the field of water treatment, can solve problems such as iron-containing precipitated sludge, achieve the effect of reducing treatment costs and eliminating the generation of iron-containing precipitated sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

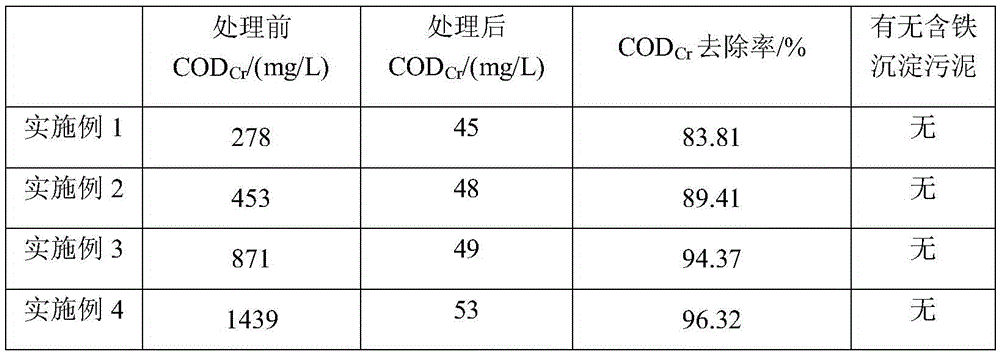

[0035] Get 1000ml rifampicin production wastewater, COD Cr to 278mg / L, adjust the pH value of the wastewater to 4.0, add 3.24ml of 30% hydrogen peroxide, 1.32g of ferrous sulfate heptahydrate, enter the Fenton fluidized bed, the aeration flow rate is 2.5L / h, and the Fenton oxidation reaction time is 100 Minutes, the wastewater after Fenton oxidation treatment enters the membrane separation reactor after passing through the security filter, the effluent can reach the standard for discharge or reuse, and the concentrated water passes through the catalyst to become 3 The photocatalytic reactor returned to the Fenton fluidized bed, mixed with the new rifampicin production wastewater, adjusted the pH value and added hydrogen peroxide, and the effluent COD Cr It is 45mg / L, which meets the discharge requirements of "Integrated Wastewater Discharge Standard" (GB8978-1996), and no iron-containing precipitated sludge is produced.

Embodiment 2

[0037] Take 1000ml rifampicin wastewater, COD Cr 453mg / L, adjust the pH value of the wastewater to 3.5, add 4.53ml of 30% hydrogen peroxide, 2.78g of ferrous sulfate heptahydrate, enter the Fenton fluidized bed, the aeration flow rate is 3L / h, and the Fenton oxidation reaction time is 90 minutes , the waste water after Fenton oxidation treatment enters the nanofiltration membrane separation reactor through the security filter, and the effluent can reach the standard for discharge or reuse. After Fuping production wastewater is mixed, adjust the pH value and add hydrogen peroxide, the effluent COD Cr It is 48mg / L, which meets the discharge requirements of the "Integrated Wastewater Discharge Standard" (GB8978-1996), and no iron-containing precipitated sludge is produced.

Embodiment 3

[0039] Take 1000ml rifampicin wastewater, COD Cr to 871mg / L, adjust the pH value of the wastewater to 3.0, add 5.81ml of 30% hydrogen peroxide, 1.78g of ferrous sulfate heptahydrate, enter the Fenton fluidized bed, the aeration flow rate is 3.6L / h, and the Fenton oxidation reaction time is 80 Minutes, the wastewater after Fenton oxidation treatment passes through the security filter and then enters the nanofiltration membrane separation reactor, the effluent can reach the standard for discharge or reuse, and the concentrated water passes through the catalyst to become SnO 2 The photocatalytic reactor returns to the Fenton fluidized bed, mixes with the new rifampicin wastewater, adjusts the pH value and adds hydrogen peroxide, and the effluent COD Cr It is 49mg / L, which meets the discharge requirements of "Integrated Wastewater Discharge Standard" (GB8978-1996), and no iron-containing precipitated sludge is produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com