Pretreatment method of ferment antibiotic fungi residues

A technology of antibiotic bacteria residue and pretreatment, applied in fermentation, waste fuel, etc., can solve the problems of difficult release of intracellular organic matter, difficult to fully utilize, low efficiency of methane production steps, etc., to improve efficiency, promote metabolic activity, and high-efficiency metabolism Effects of Activity and Resource Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

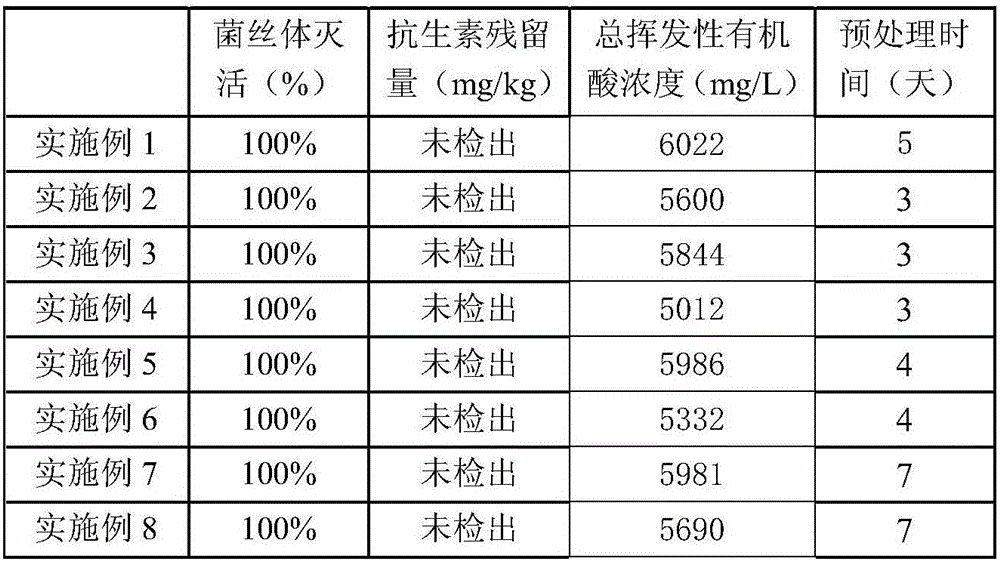

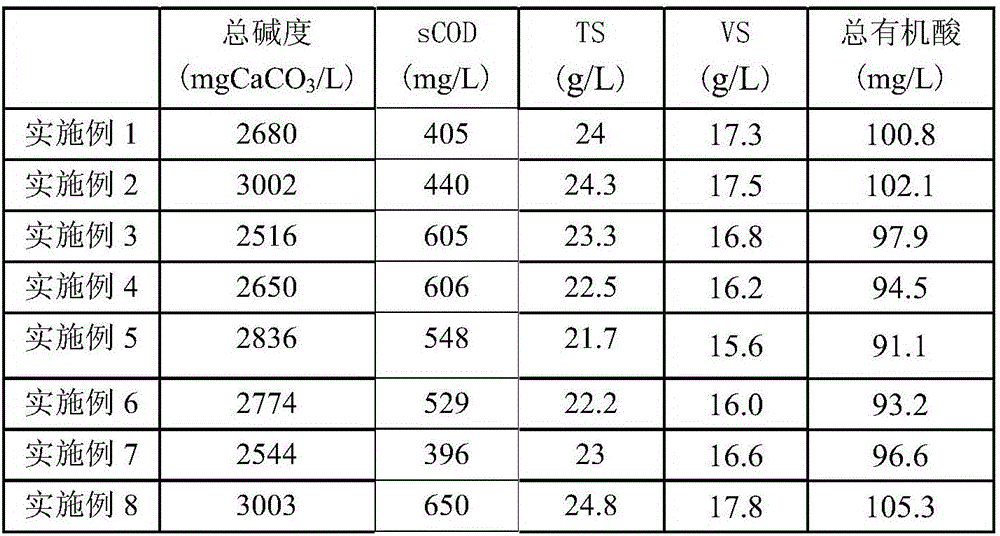

Embodiment 1

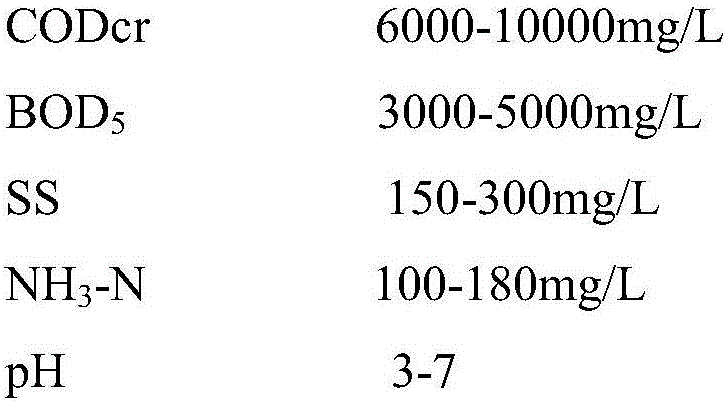

[0069] The harmless treatment of embodiment 1 oxytetracycline bacterium slag

[0070] 1. Preparation of strains and sludge

[0071] 1-1) Preparation of thermophilic acid-producing bacteria

[0072] The thermophilic strains in Table 2 were inoculated on LB agar culture (tryptone 10g / L, yeast extract 5g / L, sodium chloride 10g / L, agar 15-20g / L, pH7), respectively, at 55°C Under anaerobic culture; then select the colonies with good growth status (big colonies) and inoculate them in fresh LB liquid medium (tryptone 10g / L, yeast extract 5g / L, sodium chloride 10g / L, pH7 ), anaerobic enrichment culture at 55°C until the biomass of the strains in the liquid medium increased to (1-2)×10 8Bacteria / ml; then the culture solution of 7 strains of thermophilic bacteria was mixed in proportion to obtain thermolytic acid-producing bacteria, which were inoculated in the reactor to start the ultra-high temperature anaerobic fermentation treatment, among which 7 strains of thermophilic bacteria ...

Embodiment 2

[0118] The harmless treatment of embodiment 2 penicillin scum

[0119] 1. Preparation of strains and sludge

[0120] 1-1) Preparation of thermophilic acid-producing bacteria

[0121] Except that the inoculation ratio of the 7 strains of thermolytic acid-producing bacteria is 0.8:1:1.2:1:1.2:0.8:1, the rest are the same as step 1-1) in Example 1.

[0122] In the present invention, Sarcina, Clostridium, Anaerobaculum, Coprothermobacter, Fervidobacterium, Caloranerobacter, the proportioning of Thermus in the thermophilic acid-producing bacteria except 0.8:1:1.2:1:1.2:0.8:1, the dosage proportioning is (0.8 -1.2):(0.8-1.2):(0.8-1.2):(0.8-1.2):(0.8-1.2):(0.8-1.2):(0.8-1.2) are applicable to the present invention.

[0123] 1-2) Preparation of medium temperature digested sludge and municipal surplus sludge

[0124] Medium temperature digested sludge, municipal residual sludge are the same as in step 1-2) in embodiment 1;

[0125] 2. Start-up treatment of ultra-high temperature an...

Embodiment 3

[0145] The harmless treatment of embodiment 3 cephalosporin slag

[0146] 1. Preparation of strains and sludge

[0147] 1-1) Preparation of thermophilic acid-producing bacteria

[0148] Except that the inoculation ratio of the 7 strains of thermolytic acid-producing bacteria is 1:1.2:1:0.8:0.8:1:1.2, the rest are the same as step 1-1) in Example 1.

[0149] In the present invention, arcina, Clostridium, Anaerobaculum, Coprothermobacter, Fervidobacterium, Caloranerobacter, the proportioning of Thermus except 1:1.2:1:0.8:0.8:1:1.2 in the thermophilic acid-producing bacteria, the dosage proportioning is (0.8 -1.2):(0.8-1.2):(0.8-1.2):(0.8-1.2):(0.8-1.2):(0.8-1.2):(0.8-1.2) are applicable to the present invention.

[0150] 1-2) Preparation of medium temperature digested sludge and municipal surplus sludge

[0151] Medium temperature digested sludge, municipal residual sludge are the same as in step 1-2) in embodiment 1;

[0152] 2. Start-up treatment of ultra-high temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com