Method for treating waste water of antibiotic production

A technology for the production of waste water and treatment methods, applied in biological water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high operating cost, blockage, pollution, etc., and achieve low treatment cost, simple process, The effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

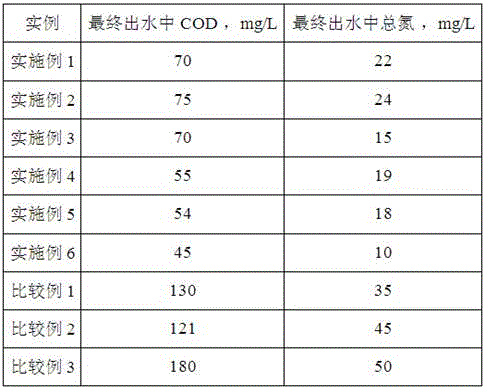

Embodiment 1

[0041] An antibiotic factory produces mixed wastewater produced by lincomycin, rifamycin, etc. The wastewater quality is: COD (Cr method, the same below) 15000mg / L, salt content 1.2wt%, suspended solids 5000mg / L, ammonia nitrogen 200mg / L, pH 7.5.

[0042] The waste water is treated by the method of the present invention. First, air is dissolved in water at 0.35MPa, and then the dissolved air is sent to the air flotation tank. The formed microbubbles bring some pollutants to the water surface and are removed. The concentration of suspended solids in the effluent Reduced to below 1500mg / L. The flotation water enters the ozone reactor. The ozone oxidant is provided by the ozone generator. The dosage of the ozone oxidant is 40mg / L wastewater, the ozone oxidant gas inlet concentration is 100mg / L, and the hydraulic retention time of the wastewater in the reactor is 30min. Ozone oxidation effluent BOD 5 / COD≥0.6. The oxidized effluent is coagulated and precipitated, the dosage of pol...

Embodiment 2

[0044] A certain antibiotic factory produces mixed wastewater produced by nalidixic acid. The wastewater quality is: COD (Cr method, the same below): 12000mg / L, salt content 1.5wt%, suspended solids 10000mg / L, ammonia nitrogen 200mg / L, pH 7.5 .

[0045] The waste water is treated by the method of the present invention. First, air is dissolved in water at 0.35MPa, and then the dissolved air is sent to the air flotation tank. The formed microbubbles bring some pollutants to the water surface and are removed. The concentration of suspended solids in the effluent Reduced to below 2000mg / L. The flotation water enters the ozone reactor. The ozone oxidant is provided by the ozone generator. The dosage of the ozone oxidant is 35mg / L wastewater, the ozone oxidant gas inlet concentration is 100mg / L, and the hydraulic retention time of the wastewater in the reactor is 30min. Ozone oxidation effluent BOD 5 / COD≥0.4. The oxidized effluent is coagulated and precipitated. The dosage of polyac...

Embodiment 3

[0047] An antibiotic factory produces mixed wastewater produced by lincomycin, rifamycin, etc. The wastewater quality is: COD (Cr method, the same below) 15000mg / L, salt content 1.2wt%, suspended solids 5000mg / L, ammonia nitrogen 200mg / L, pH 7.5.

[0048] The waste water is treated by the method of the present invention. First, air is dissolved in water at 0.35MPa, and then the dissolved air is sent to the air flotation tank. The formed microbubbles bring some pollutants to the water surface and are removed. The concentration of suspended solids in the effluent Reduced to below 1500mg / L. The flotation water enters the ozone reactor. The ozone oxidant is provided by the ozone generator. The dosage of the ozone oxidant is 40mg / L wastewater, the ozone oxidant gas inlet concentration is 100mg / L, and the hydraulic retention time of the wastewater in the reactor is 30min. Ozone oxidation effluent BOD 5 / COD≥0.4. The oxidized effluent is coagulated and precipitated, the dosage of pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com