Non-oriented electrical steel produced by sheet continuous casting and rolling and method thereof

A technology of oriented electrical steel, continuous casting and rolling, which is applied in the field of non-oriented electrical steel, can solve the problems that the thin slab continuous casting and rolling process is difficult to realize, cannot completely eliminate coarse columnar crystals, and cannot reflect cost advantages, etc., and achieves improvement Market competitiveness, reasonable design, excellent steel plate magnetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

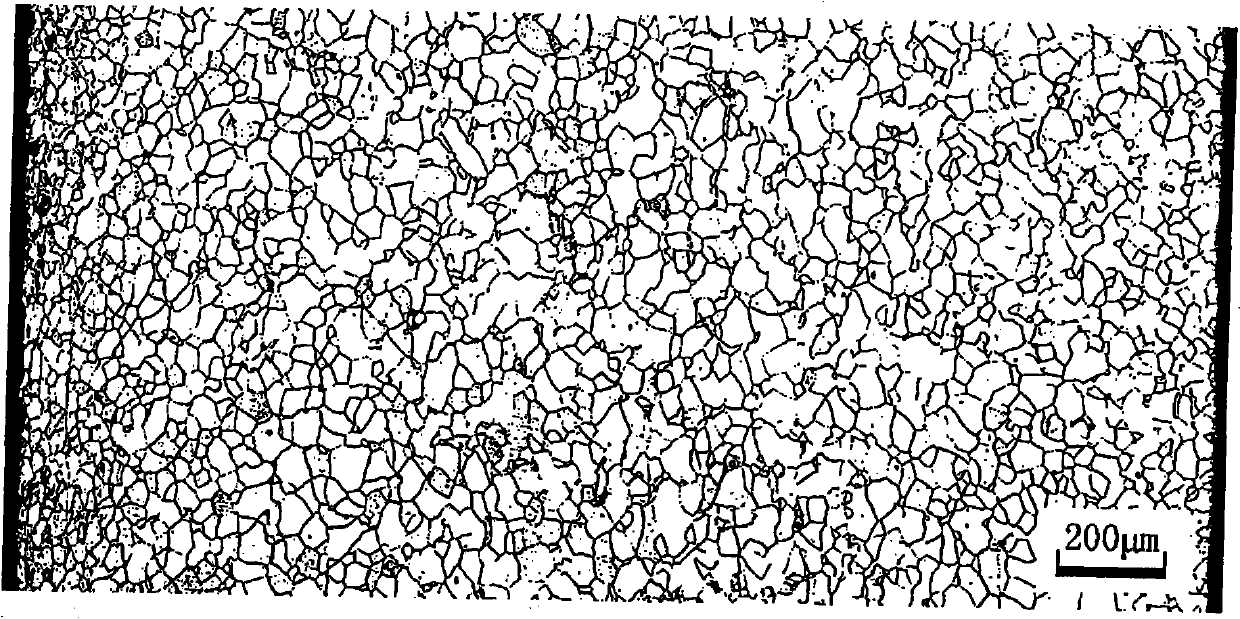

Embodiment 1

[0028] The chemical composition and weight percentage of non-oriented electrical steel produced by continuous casting and rolling of thin plates are: C: 0.0031%, Si: 1.0%, Al: 0.50%, Si+2Al: 2.0%, Mn: 0.5%, P: 0.10%, S: 0.0072%, N: 0.0048%, Ti: 0.006%, Ca: 0.01%, Cu: 0.3%, Ni: 0.08%, and the rest are iron and unavoidable impurities.

[0029] The production right adopts the method of non-oriented electrical steel produced by continuous casting and rolling of thin plates, the steps of which are as follows:

[0030] 1) Smelting and vacuum treatment;

[0031] 2) Carry out continuous casting, control the thickness of the cast slab at 50 mm, and control the casting speed at 3 m / min;

[0032] 3) Perform soaking, control the temperature of the slab before entering the furnace at 850-855°C, and control the soaking temperature at 1080-1085°C;

[0033] 4) Carry out finish rolling, control the reduction rate of each pass in the first two passes to 50%, and control the finish rolling tem...

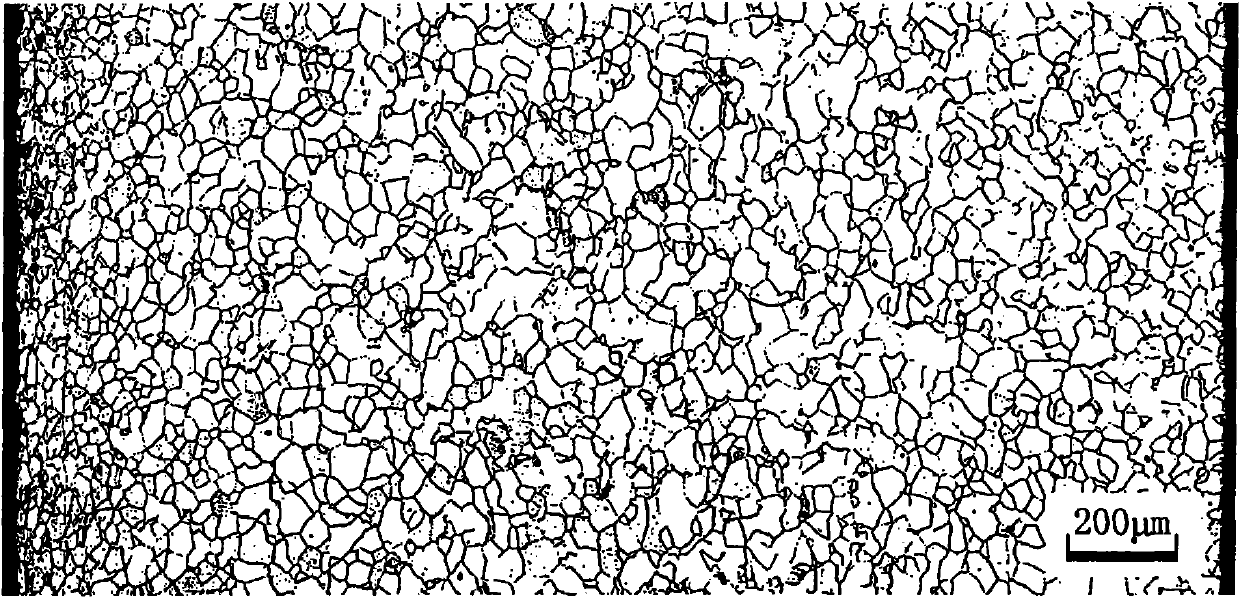

Embodiment 2

[0040] The chemical composition and weight percentage of non-oriented electrical steel produced by continuous casting and rolling of thin plates are: C: 0.0045%, Si: 1.25%, Al: 0.25%, Si+2Al: 1.75%, Mn: 0.85%, P: 0.075%, S: 0.008%, N: 0.0042%, Ti: 0.008%, Ca: 0.0093%, Cu: 0.45%, and the rest are iron and unavoidable impurities.

[0041] The production right adopts the method of non-oriented electrical steel produced by continuous casting and rolling of thin plates, the steps of which are as follows:

[0042] 1) Smelting and vacuum treatment;

[0043] 2) Carry out continuous casting, control the thickness of the cast slab at 60 mm, and control the casting speed at 3.5 m / min;

[0044] 3) Perform soaking, control the temperature of the slab before entering the furnace at 860-865°C, and control the soaking temperature at 1080-1085°C;

[0045] 4) Carry out finish rolling, control the reduction rate of each pass in the first two passes to 58%, and control the finish rolling temper...

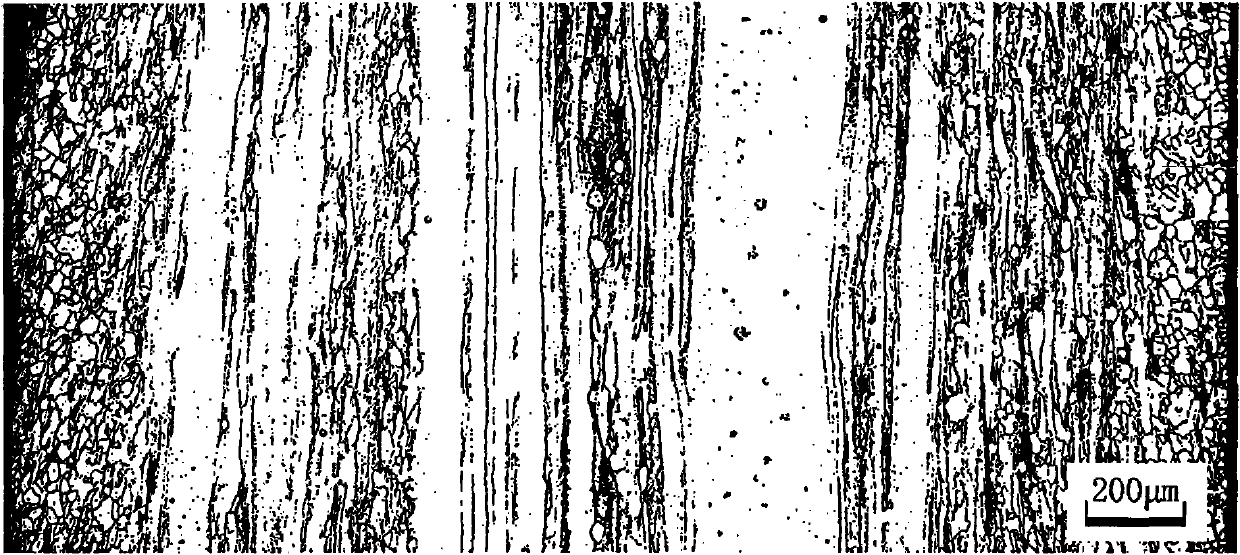

Embodiment 3

[0052] The chemical composition and weight percentage of non-oriented electrical steel produced by thin plate continuous casting and rolling are: C: 0.0038%, Si: 1.6%, Al: 0.25%, Si+2Al: 2.1%, Mn: 0.90%, P: 0.095%, S: 0.068%, N: 0.0038%, Ti: 0.0068%, Ca: 0.008%, Ni: 0.3%, and the rest are iron and unavoidable impurities.

[0053] The production right adopts the method of non-oriented electrical steel produced by continuous casting and rolling of thin plates, the steps of which are as follows:

[0054] 1) Smelting and vacuum treatment;

[0055] 2) Carry out continuous casting, control the thickness of the cast slab at 65 mm, and control the casting speed at 3.5 m / min;

[0056] 3) Perform soaking, control the temperature of the slab before entering the furnace at 900-904°C, and control the soaking temperature at 1090-1098°C;

[0057] 4) Carry out finish rolling, control the reduction rate of each pass in the first two passes to 60%, and control the finish rolling temperature t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com