Pre-treatment method for highly-effective saccharification of lignocellulose

A lignocellulose and pretreatment technology, applied in chemical instruments and methods, sugar production, sugar derivatives, etc., can solve the problems of lower sugar yield and raw material utilization, high production cost, high energy consumption for processing, and achieve Save production and lye recovery costs, reduce production safety hazards, and achieve a high conversion rate of cellulose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

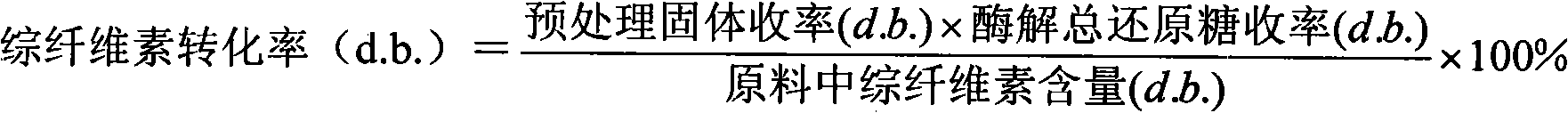

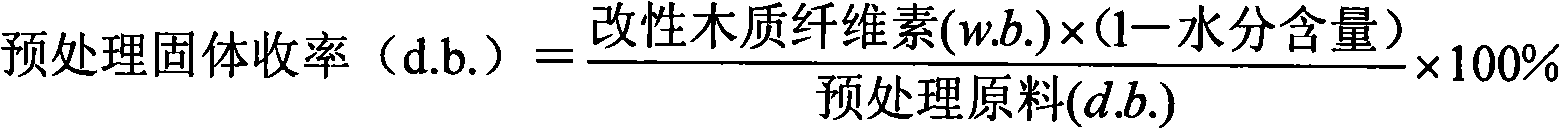

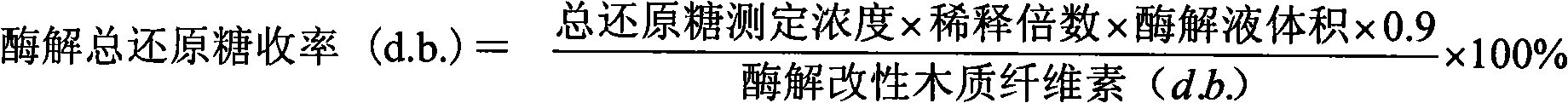

Method used

Image

Examples

Embodiment 1

[0040] Coarsely pulverize the dried corn stalks until they pass through a 20-mesh sieve for later use. Get 40g raw material, be 10 according to the mass ratio of lye and lignocellulose, NaOH solution concentration is 2% to mix according to mass volume ratio; The lye was pulverized for 1h, and the obtained slurry was centrifuged at 5,000rpm and 30min, and all the centrifuged liquid and modified lignocellulose were collected respectively; , Japan) in reclaiming the alkali in the liquid; Weigh the above-mentioned modified lignocellulose equivalent to 4g of dry matter in a container, add water to prepare a modified lignocellulose feed solution with a concentration of 1%; Adjust the pH value to 4.7; add cellulase (Zhaodong Guoke North Enzyme Co., Ltd., enzyme activity is 10,000u / g) 0.125g / g (modified lignocellulose dry matter benchmark) to the feed liquid; place the container In a water bath at 50°C, stir every 4 hours, and control the enzymatic hydrolysis time at 120 hours; sampl...

Embodiment 2

[0042] Coarsely pulverize the dry rice straw raw material until passing through a 60-mesh sieve for later use. Get 100g of raw material, according to the mass ratio of lye and lignocellulose is 6, KOH solution concentration is mixed according to mass volume ratio is 3%; The lye was crushed for 1 hour, and the obtained slurry was centrifuged at 9,000 rpm for 10 minutes to collect all the centrifuged liquid and modified lignocellulose; the centrifuged liquid recovered the alkali in the liquid by electrodialysis, and the method was the same as in Example 1; Put the above-mentioned modified lignocellulose equivalent to 8 g of dry matter in a container, add water to prepare a modified lignocellulose feed solution with a concentration of 2%; adjust the pH value of the feed solution to 4.9 with sulfuric acid solution; add fiber Sulfase (Ningxia Hersbit Biotechnology Co., Ltd., enzyme activity is 10,000u / g) 0.08g / g (modified lignocellulose dry matter basis); the container is placed in...

Embodiment 3

[0044] The dried cypress bark raw material is coarsely crushed to pass through a 40-mesh sieve for later use. Get 200g of raw material, according to the mass ratio of lye and lignocellulose is 6, the NaOH solution concentration is mixed according to the mass volume ratio of 1%; The lye was crushed for 1 hour, and the obtained slurry was centrifuged at 9,000 rpm for 10 minutes to collect all the centrifuged liquid and modified lignocellulose; the centrifuged liquid recovered the alkali in the liquid by electrodialysis, and the method was the same as in Example 1; Put the above-mentioned modified lignocellulose equivalent to 8 g of dry matter in a container, add water to prepare a modified lignocellulose feed solution with a concentration of 2%; adjust the pH value of the feed solution to 4.8 with sulfuric acid solution; add fiber Sulfase (Ningxia Hersbit Biotechnology Co., Ltd., enzyme activity is 10,000u / g) 0.12g / g (modified lignocellulose dry matter basis); the container is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com