A method for treating organic chemical wastewater

A technology for chemical wastewater and wastewater, applied in chemical instruments and methods, water/sewage treatment, aerobic process treatment, etc., can solve the problems of high wastewater treatment process requirements and high treatment costs, and achieve faster biological reaction speed, economical and efficient treatment. , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] Preparation of microbial culture medium

[0067] The dried flour, blood meal and bone meal are mixed according to the mass fraction of 60% flour, 30% blood meal and 10% bone meal, and sieved to control the particle size below 0.1mm.

[0068] The activated carbon fiber is processed to 2-4mm, soaked in 60-68% nitric acid solution for 2-4 hours, washed with distilled water until neutral, and dried at 100°C to obtain the modified activated carbon fiber.

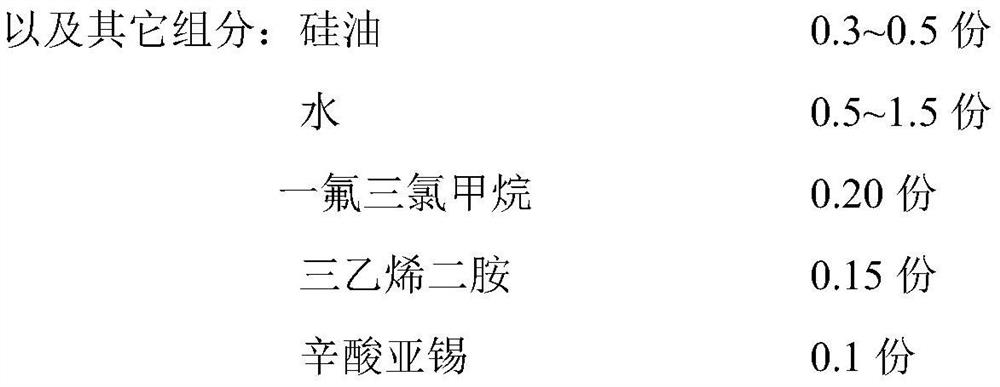

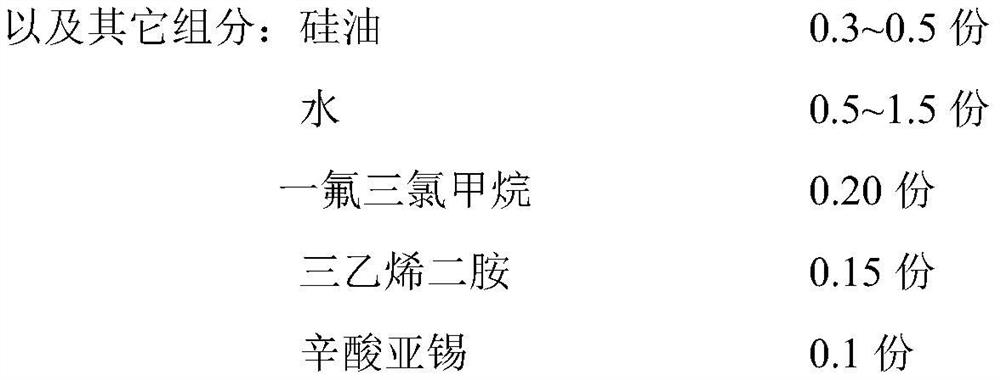

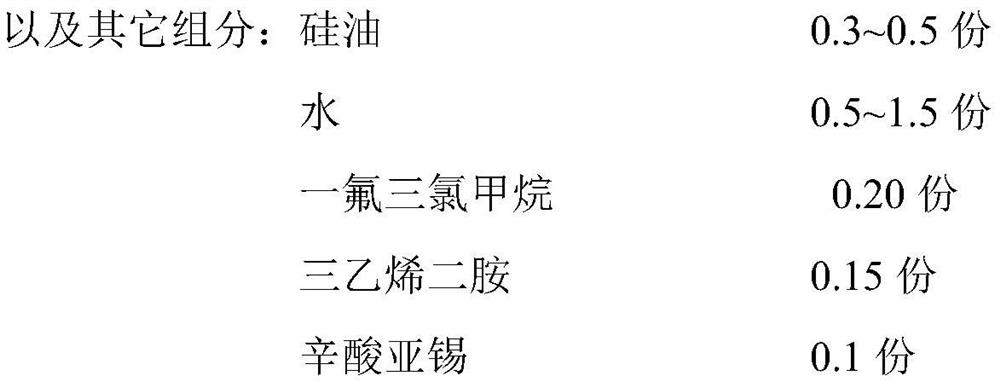

[0069] Preparation of Polyurethane Bioactive Carrier A

[0070] Component ①: Polyether 330: 70-75 parts

[0071] Microbial culture medium 1.0~2.0 parts

[0072] After mixing the above raw materials in sequence, stir mechanically at 20°C for 10 minutes to obtain component ①.

[0073] Component ②: 25-30 parts of toluene diisocyanate

[0074] Modified activated carbon fiber 2.0~5.0 parts

[0075] After mixing the above raw materials in sequence, stir mechanically at 20°C for 10 minutes to obtain component ②.

[0076] ...

Embodiment 1

[0102] Add polyurethane bioactive carrier A and anaerobic microorganisms into the anaerobic reactor, and after 2 months of starting, the COD cr 30000mg / L, NH 4 + -N is 200mg / L Thymopentin processing and production wastewater is adjusted to neutral during the adjustment, the production wastewater after adjustment and homogenization enters the anaerobic reactor, reacts at 40°C for 72h, and measures the COD of the effluent cr 800mg / L, NH 4 + -N is 150mg / L. At this step, COD cr The removal rate is 97.33%, NH 4 + -N removal rate was 25%.

[0103] The water quality treated in the anaerobic reactor is re-entered into the aerobic reactor, and immobilized microbial carrier A and microorganism B350 (BIO-SYSTEM, USA) are added to the aerobic reactor, and reacted at 30°C for 24h , measured water COD cr 100mg / L, NH 4 + -N is 20mg / L. At this step, COD cr The removal rate is 87.5%, NH 4 + -N removal rate is 86.67%.

[0104]The water quality after the treatment in the aerobic ...

Embodiment 2

[0107] Add polyurethane bioactive carrier B into the anaerobic reactor, add polyurethane bioactive carrier A and anaerobic microorganisms into the anaerobic reactor, and after 2 months of starting, the COD cr 30000mg / L, NH 4 + -N is 200mg / L Thymopentin processing and production wastewater is adjusted to neutral during the adjustment, the production wastewater after adjustment and homogenization enters the anaerobic reactor, reacts at 40°C for 72h, and measures the COD of the effluent cr 1200mg / L, NH 4 + -N is 150mg / L. At this step, COD cr The removal rate is 96%, NH 4 + -N removal rate was 25%.

[0108] The water quality treated in the anaerobic reactor is re-entered into the aerobic reactor, and immobilized microbial carrier A and microorganism B350 (BIO-SYSTEM, USA) are added to the aerobic reactor, and reacted at 30°C for 24h , measured water COD cr 500mg / L, NH 4 + -N is 100mg / L. At this step, COD cr The removal rate was 58.33%, NH 4 + -N removal rate was 30%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com