Integral sewage disposal process for strengthening sludge filtrating technology

A sewage treatment method and sludge filtration technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, flocculation/sedimentation water/sewage treatment, etc. High operating cost and narrow water quality range to achieve good removal of organic matter, improved mud-water separation efficiency, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

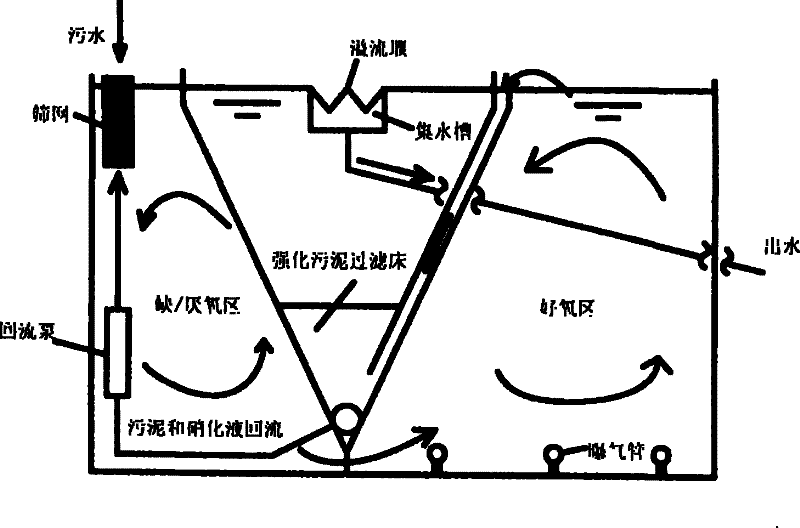

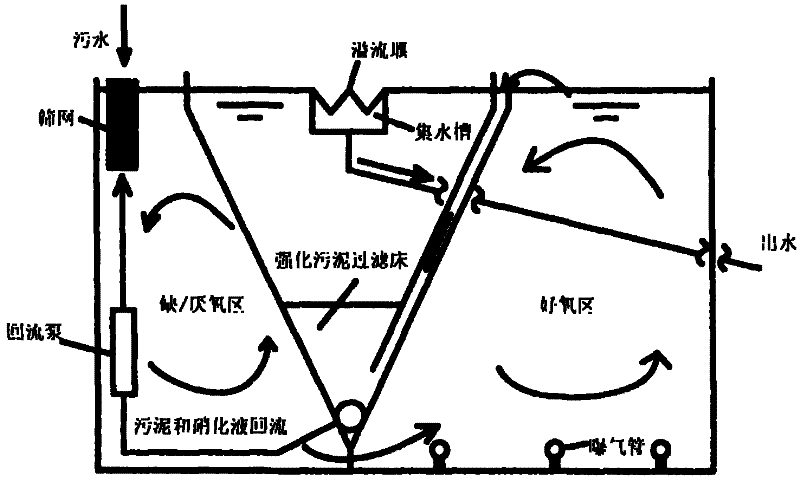

[0023] The present invention will be further described below in conjunction with accompanying drawing.

[0024] In practical application, the present invention does not need to set up a primary sedimentation tank before biological treatment, and has good hydraulic flexibility. At the water inlet of the bioreactor, it is only necessary to set up an appropriate grid or screen device, and if it is a large water plant, an additional sand settling device can meet the requirements.

[0025]The device adopting the method of the invention is easy to be produced in modularized form, so it can be constructed on site during actual engineering construction, and can also be transported to the site for installation after being prefabricated in a factory. The sewage treatment plant built on site adopts concrete or reinforced tank body, and installs a secondary settling tank made of polypropylene or epoxy coated steel or stainless steel material with enhanced sludge filtration. This secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com