Integrated precipitating and mud collection backflow device

A reflux device, an integrated technology, applied in the fields of chemical industry and environmental protection, can solve the problems that organic matter cannot be degraded well, the contact between wastewater and sludge is insufficient, and the treatment efficiency is reduced, so as to achieve the improvement effect and the biochemical performance of sewage, It is not easy to short-circuit and channel flow, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

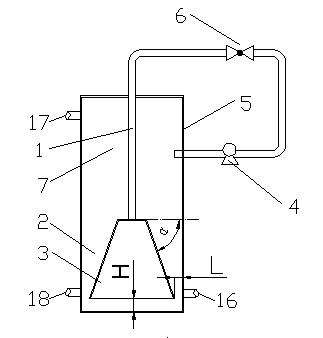

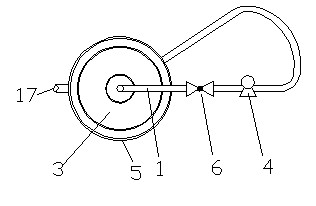

[0024] Depend on figure 1 and figure 2 The integrated settling sludge collection and return device includes a reactor 5 with a settling zone 2 and a reaction zone 7 inside. The reactor 5 is in the shape of a shell, and the lower part of the shell cavity of the reactor 5 is the settling zone 2. The upper part of the shell cavity of the reactor 5 is the reaction zone 7, that is, the reaction zone 7 in the reactor 5 is integrated with the precipitation zone 2, and the reaction zone 7 is communicated with the precipitation zone 2; the reactor 5 is provided with a waste water inlet 16, Outlet 17 and mud discharge port 18, waste water inlet 16, outlet 17 and mud discharge port 18 all have on-off valves, funnel 3 is established in sedimentation zone 2, and described funnel 3 is conical, and the slope of funnel 3 and the angle of horizontal direction α is between 45°-60°. The big mouth of funnel 3 faces downward, and a gap is provided between the side and bottom of funnel 3 and the...

Embodiment 2

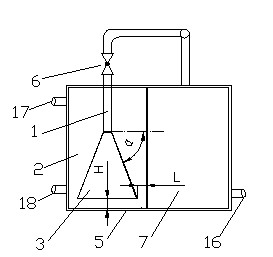

[0028] Depend on image 3 and Figure 4 The shown integrated settling mud collection and return device includes a reactor 5 with a settling zone 2 and a reaction zone 7 inside. The reactor 5 is in the shape of a shell, and the reactor 5 is provided with a waste water inlet 16, an outlet 17 and a sludge discharge Port 18, waste water inlet 16, outlet 17 and mud discharge port 18 all have on-off valves, a vertical baffle is arranged in the reactor 5 housing, and one end of the baffle 8 is fixed on the inner wall of the reactor 5 housing. The other end of the baffle 8 is spaced from the inner wall of the reactor 5, and the inner chamber of the reactor 5 housing on one side of the baffle 8 is the precipitation zone 2, and the inner chamber of the reactor 5 housing on the other side of the baffle 8 is the reaction zone. Area 7, reaction area 7 is positioned at the side of precipitation area 2, and reaction area 7 and precipitation area 2 are communicated at intervals between the e...

Embodiment 3

[0032] Depend on Figure 5 and Figure 6The shown integrated settling sludge collection and reflux device differs from Example 2 in that: the reactor 5 is provided with a horizontal plate 12 extending left and right, and one side of the horizontal plate 12 is provided with longitudinal folds at intervals. Baffles 11 form a settling zone 2 between adjacent baffles 11. Among the two adjacent baffles 11, one end of one of the baffles 11 is fixed on the horizontal plate 12, and the other end is connected to the inner wall of the reactor 5. There is an interval, and one end of another baffle 11 is fixed on the inner wall of the reactor 5, and there is a gap between the other end and the horizontal plate 12; similarly, the other side of the horizontal plate 12 is also provided with longitudinal baffles 10 at intervals. The reaction zone 7 is formed between the adjacent baffles 10, and among the two adjacent baffles 10, one end of one of the baffles 10 is fixed on the horizontal pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com