Water-treating bipolar pulse discharge process

A bipolar pulse, water treatment technology, applied in the fields of magnetic field/electric field water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc. Efficient water sterilization, prolonging life and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

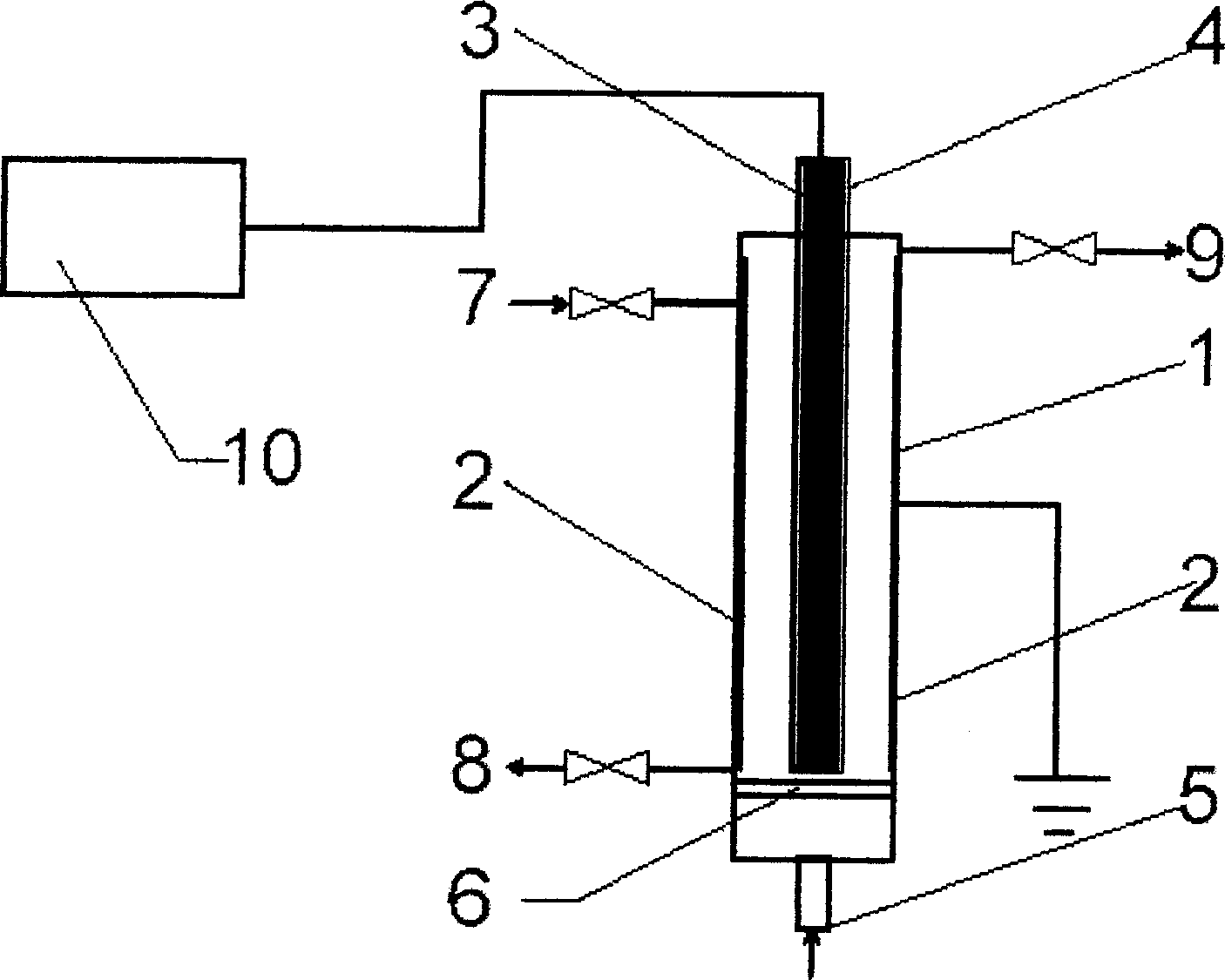

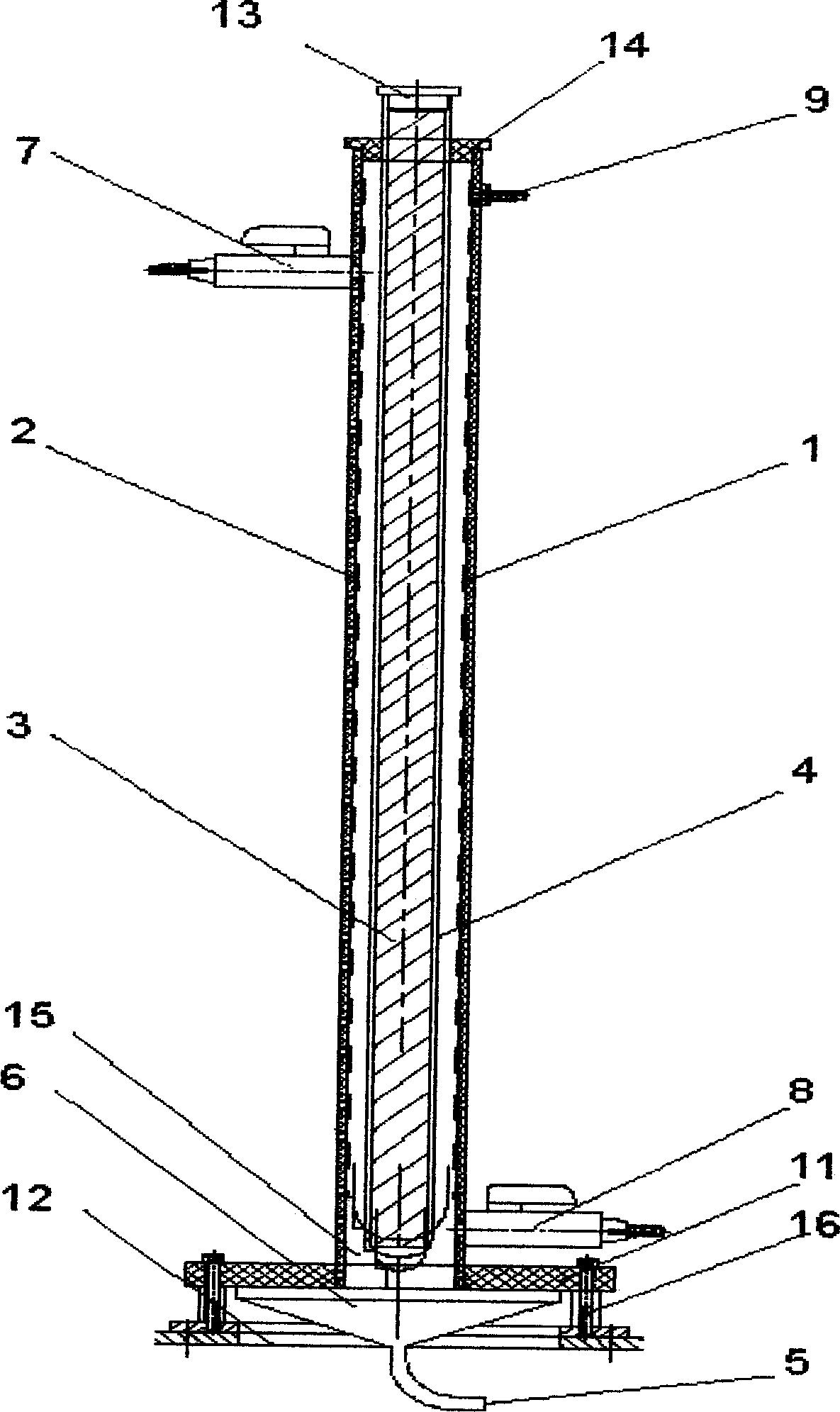

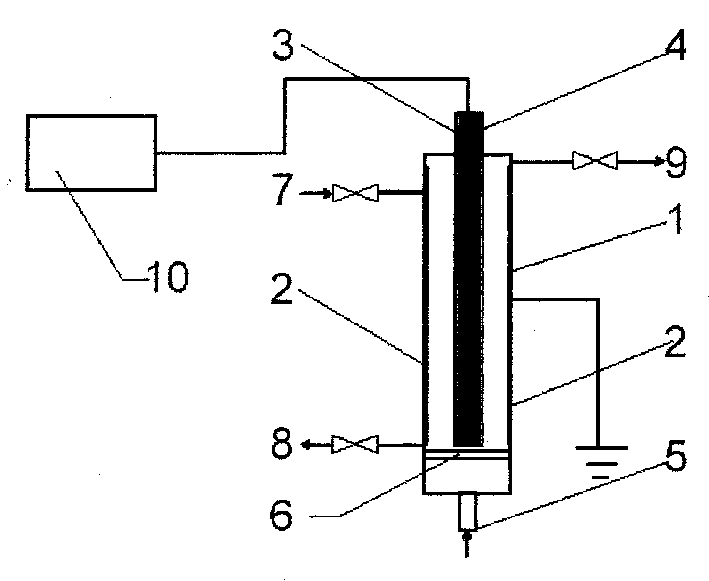

[0023] The best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] In order to better accelerate the free electrons in the discharge process without accelerating the ions to generate more active species, the power supply adopts a bipolar pulse power supply (10), and its power supply parameters are: peak-to-peak voltage 1-200 kV , The pulse rise time is 30-300 nanoseconds, and the pulse repetition frequency is 1-2000 Hz.

[0025] The reactor adopts a cylindrical reactor with a column-cylindrical electrode structure. The surface of the high-voltage electrode (3) in contact with the gas-liquid mixture is completely covered by the glass insulating medium (4), so that the metal high-voltage electrode (3) and the gas-liquid The mixture is separated, and at the same time, it is ensured that the insulating medium has no obvious edges, corners and protrusions, so as to avoid the occurrence of strong partial disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com