Catalyst for wastewater treatment and method for wastewater treatment using said catalyst

A wastewater treatment and catalyst technology, applied in the direction of physical/chemical process catalysts, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of insufficient catalytic activity and durability, and achieve good catalytic activity and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the catalyst related to the present invention is not particularly limited, and the catalyst can be easily prepared by a known method. Methods for supporting a catalytically active component on a carrier include, for example, a kneading method, an impregnation method, an adsorption method, a spray method, an ion exchange method, and the like.

[0047] The catalyst having the above-mentioned configuration can maintain the catalytic activity and durability of the catalyst for a long time, and can provide high mechanical properties. Furthermore, using the catalyst of the present invention described above, wastewater treatment by wet oxidation treatment can provide clean water purified at a high level.

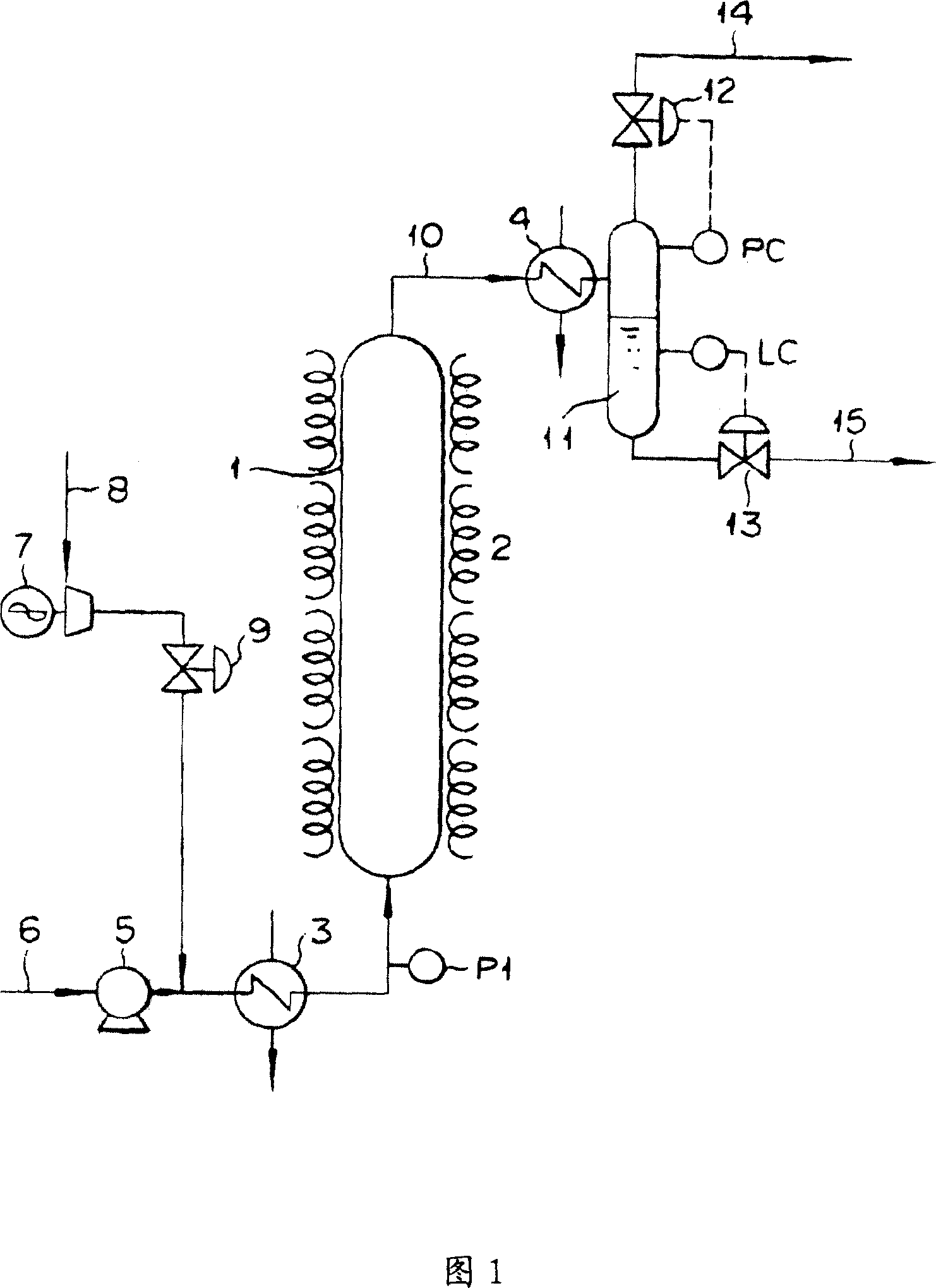

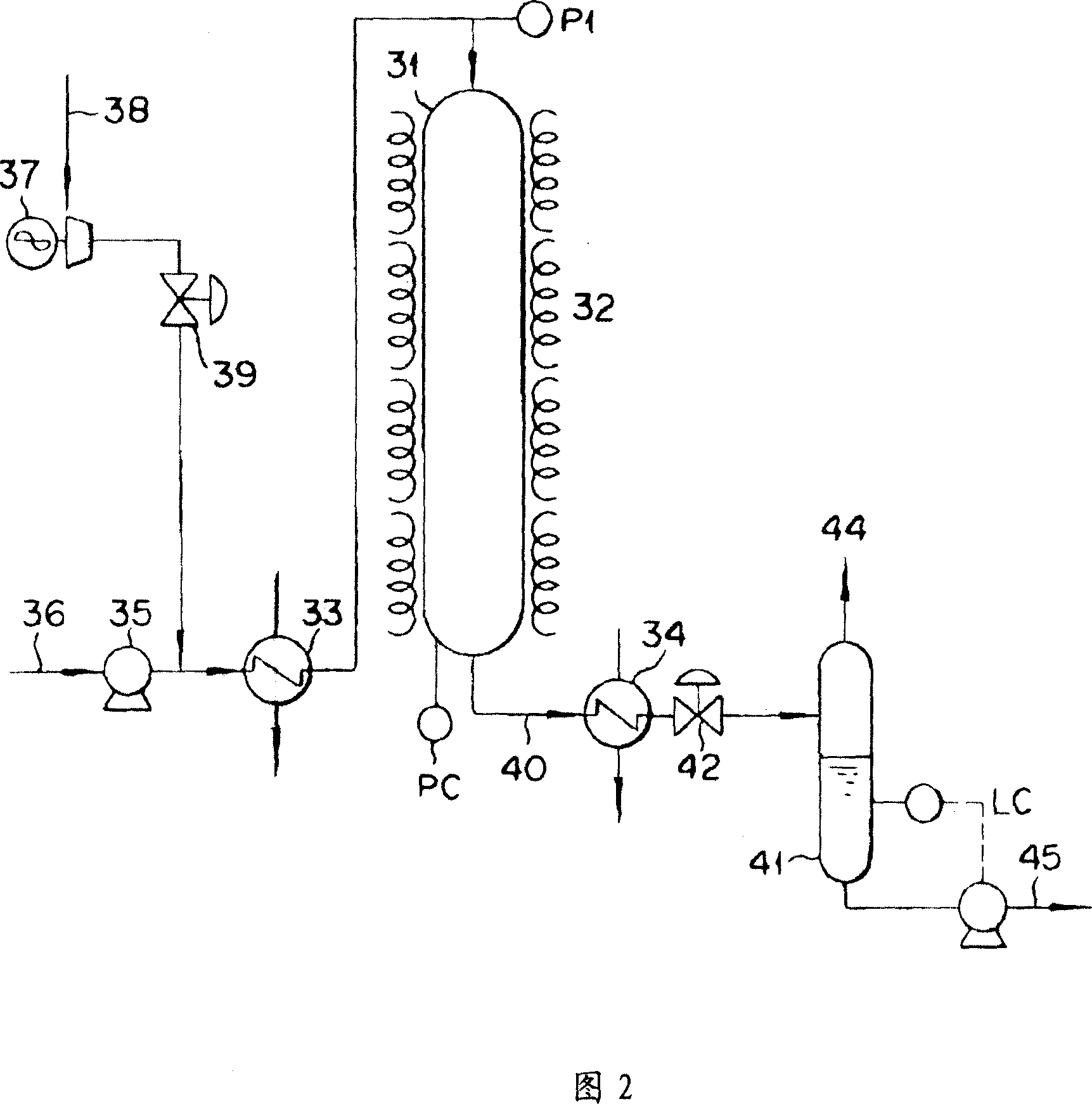

[0048] The wet oxidation treatment of wastewater using the catalyst of the present invention will be described in detail below. The type of wastewater to be treated by the wet oxidation treatment of the present invention is not particularly limited...

preparation Embodiment 1

[0090] In the preparation of the catalyst, a flaky titanium oxide support is used. The carrier has an average diameter of 5 mm, an average length of 7.5 mm, an average compressive strength of 3.4 kg / particle (a load is applied on the carrier (catalyst), when the carrier (catalyst) is destroyed, the average value of the load), 44 m 2 The specific surface area measured by the BET method per g, the solid acid content of 0.32mmol / g; the titanium oxide crystal structure forming the support is anatase type. The catalyst (A-1) was obtained by filling the carrier with an aqueous solution of the catalytically active component (the aqueous solution was absorbed by the added platinum nitrate aqueous solution, then dried at 150°C, and further subjected to combustion treatment at 300°C using a hydrogen-containing gas for 2 hours) ). Table 1 shows the main components of the produced catalyst (A-1) and their mass ratios. In addition, the specific surface area, average compressive strength,...

preparation Embodiment 2 to 7

[0092] In any one of Catalyst Preparation Examples 2 to 7, the carrier used in Catalyst Preparation Example 1 was used. Catalysts (A-2 to A-7) listed in Table 1 were prepared in the same manner as in Catalyst Preparation Example 1 except for changing a part of the raw materials in the method of filling the carrier with an aqueous solution of the catalytically active ingredient.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com