Photoelectrocatalysis and oxidation device for treating organic substance in water

A photoelectric catalysis and oxidation treatment technology, applied in the direction of oxidized water/sewage treatment, electrochemical water/sewage treatment, light water/sewage treatment, etc., can solve the problems of mass transfer, reaction rate needs to be improved, etc., to achieve treatment efficiency High, compact and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

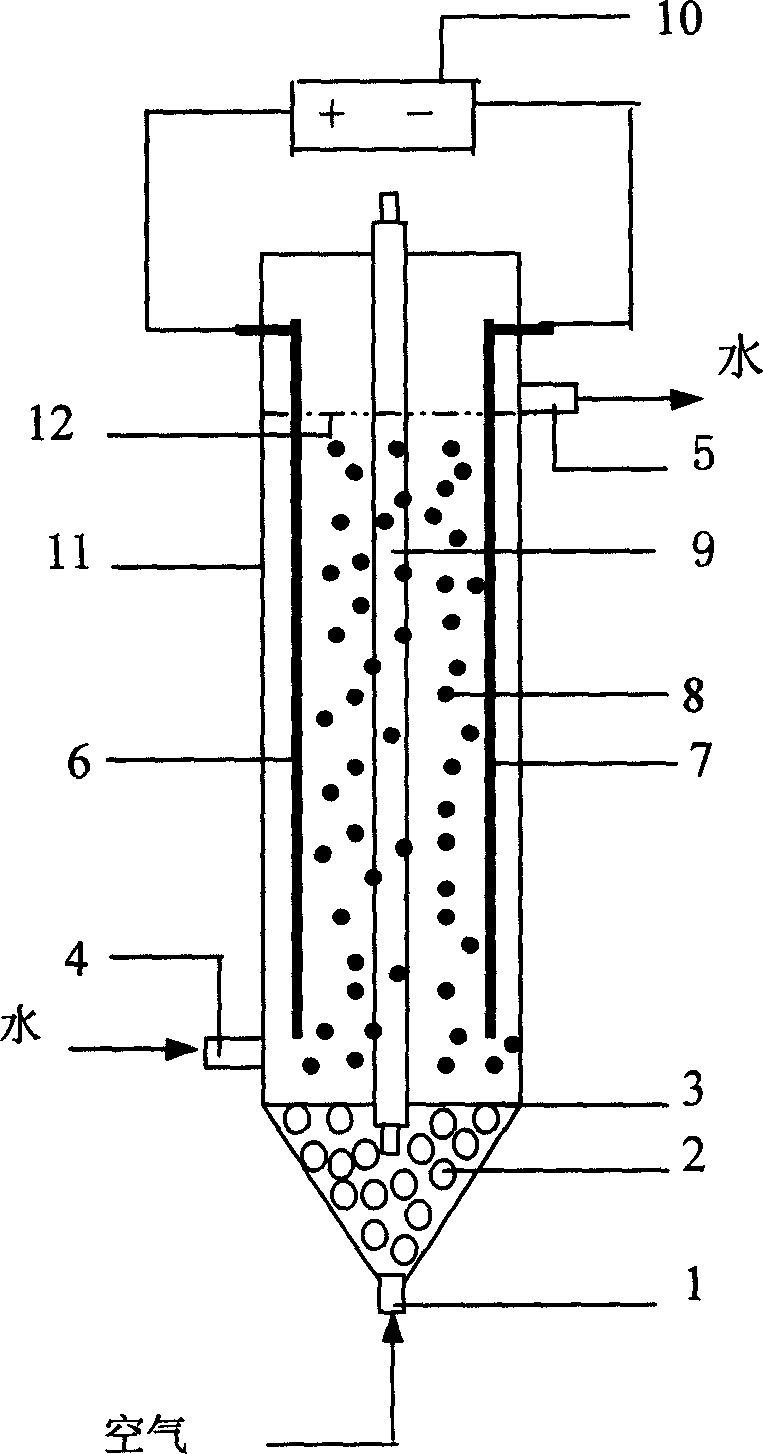

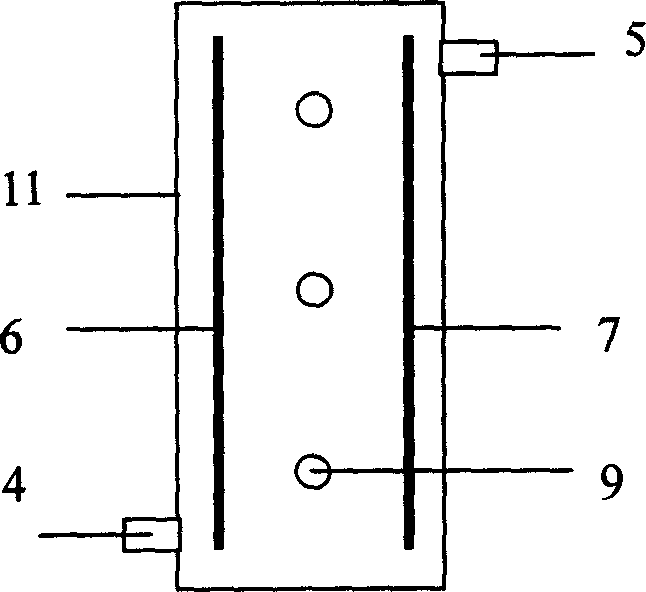

[0025] refer to figure 1 , the reaction device structure of the fluidized bed photocatalytic oxidation treatment of organic matter in water of the present invention is as follows: titanium-based oxide TiO 2 / SnO 2 The / Ti anode 6 is the anode, the air oxygen electrode cathode 7 is the cathode, and the cathode and the anode are respectively provided with electrical connectors that can be connected to a DC power supply 10; compressed air is used as the gas source; the particles are coated with commercial activated carbon and graphite powder TiO 2 Formed TiO 2 The / C fluidized particles 8 are photocatalyst particles. Compressed air enters the bottom air chamber of the reactor from the air inlet 1, and blows air into the reactor through the microporous air distribution plate 3. The two electrodes stand opposite each other, each close to a wall of the device. TiO 2 / C Fluidized particles are placed on the air distribution plate and are in a fluidized state under the action of...

Embodiment approach 2

[0028] According to the device structure and treatment process of Embodiment 1, the water-soluble humic acid solution is treated. The setting conditions are: 15W UV light source, TiO 2 / C photocatalytic fluidized particle size 1.5mm, P25 TiO 2 The concentration is 1.5g / L, and the air flow rate is 0.5m 3 / h, TiO 2 / SnO 2 / Ti is the anode, the air oxygen electrode is the cathode, the distance between the negative and positive electrodes is 8cm, and the electrode area is 20cm 2 , current density 15mA / cm 2 . After 1 hour of photoelectric catalytic reaction, the COD removal rate of 20mg / L, 120mL water-soluble humic acid solution was 86.2%, and the decolorization rate was 100%.

Embodiment approach 3

[0030] According to the device structure and treatment process of Embodiment 1, the formic acid aqueous solution is treated. The setting conditions are: 15W UV light source, TiO 2 / C photocatalytic fluidized particle size 2mm, P25 TiO 2 The concentration is 0.8g / L, and the air flow rate is 0.6m 3 / h, TiO 2 / SnO 2 / Ti is the anode, the air oxygen electrode is the cathode, the distance between the negative and positive electrodes is 15cm, and the electrode area is 20cm 2 , current density 15mA / cm 2 . After 1 hour of photoelectric catalytic reaction, the COD removal rate of 460mg / L and 120mL formic acid aqueous solution was 96.8%, and the decolorization rate was 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com