Advanced treatment method for fracturing flow-back fluid

A fracturing flowback fluid and advanced treatment technology, which is applied in the advanced treatment of fracturing flowback fluid and the treatment of fracturing flowback fluid, can solve the problems of poor treatment effect, high cost, and inability to continuously treat, and achieve cost The effect of low, lower processing cost and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

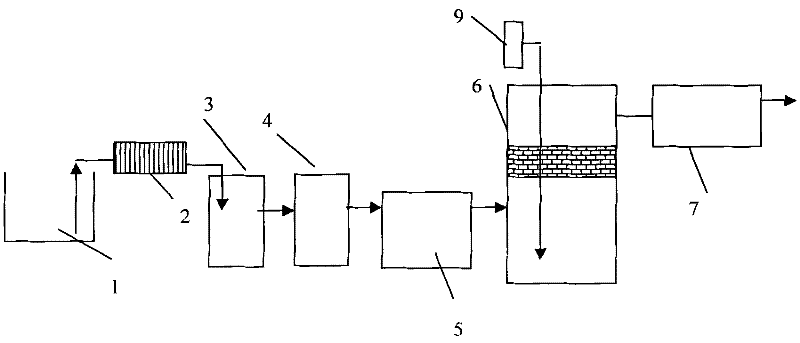

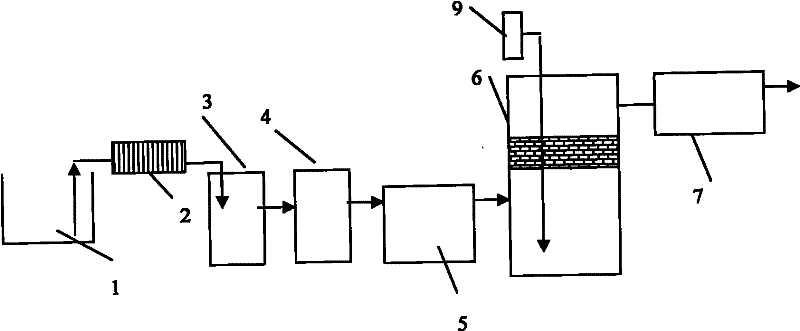

Embodiment 1

[0028] Send 100L of fracturing flowback fluid produced during the development and production of oil and gas fields into the coagulation sedimentation tank 1, adjust the pH to 8, then add 100g of potassium permanganate for pre-oxidation for 8 hours, and keep stirring at the same time, the COD removal rate is 20% ; Then add 100g PAC and 200g aluminum sulfate to carry out gel breaking treatment, after processing for 0.5 hours, enter filter press 2 and carry out pressure filtration; the waste liquid after the pressure filtration enters the water storage adjustment tank 3, after adjusting the pH to be 3, the waste liquid Pump into the oxidation tank 4, add hydrogen peroxide (concentration 30%) 300mL, ferrous sulfate 18g, react for 10 hours; the waste liquid after the reaction is sent into the secondary coagulation tank 5 again, add tannin biological extract 1g and carry out secondary mixing Coagulate, react for 2 hours, adjust the pH of the waste liquid to be 8; send the waste liqui...

Embodiment 2

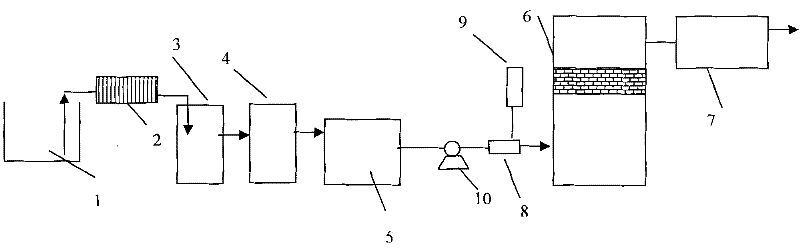

[0030] Send 250L of fracturing flowback fluid produced during the development and production of oil and gas fields into the coagulation sedimentation tank 1, adjust the pH to 12, then add 1L hypochlorous acid for pre-oxidation for 4 hours, and keep stirring at the same time, the COD removal rate is 25%; Then add 500g PAC and 750g aluminum sulfate coagulant to carry out gel breaking treatment for 2 hours, then enter filter press 2 for filtration; the waste liquid after filtration enters water storage adjustment tank 3, after adjusting the pH to 5, the waste liquid is pumped into Oxidation tank 4, add 2.25L of hydrogen peroxide (concentration 30%), ferrous sulfate 360g, react for 5 hours; the waste liquid after the reaction is sent to secondary coagulation tank 5, add 11g of tannin biological extract for secondary coagulation , react for 0.5 hour, adjust pH to be 12; Waste liquid 220L after the secondary coagulation is pumped into mixing jet 8, open ozone generator 9 simultaneous...

Embodiment 3

[0032]Send 330L of fracturing flowback fluid produced during the development and production of oil and gas fields into the coagulation sedimentation tank 1, adjust the pH to 10, then add 300g of potassium permanganate for pre-oxidation for 6 hours, and keep stirring at the same time, the COD removal rate is 30% ; then add 990g PAC and 1320g aluminum sulfate coagulant to carry out gel breaking treatment after 1 hour, enter filter press 2 to filter; the waste liquid after filtering enters water storage adjustment tank 3, after adjusting pH to be 4, waste liquid pump Enter oxidation pool 4, add hydrogen peroxide (concentration 27%) 2.2L, ferrous sulfate 297g, react 2 hours; The waste liquid after the reaction is sent into secondary coagulation tank 5 again, adds tannin biological extract 5g and carries out secondary mixing Coagulate, react for 1 hour, adjust the pH to 10; pump 290L of waste liquid after the secondary coagulation into the mixing jet 8, and open the ozone generator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com