Advanced treatment system and method for high-concentration percolate in comprehensive garbage disposal plant

A comprehensive treatment and advanced treatment technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as pollution and inability to ensure stable effluent standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

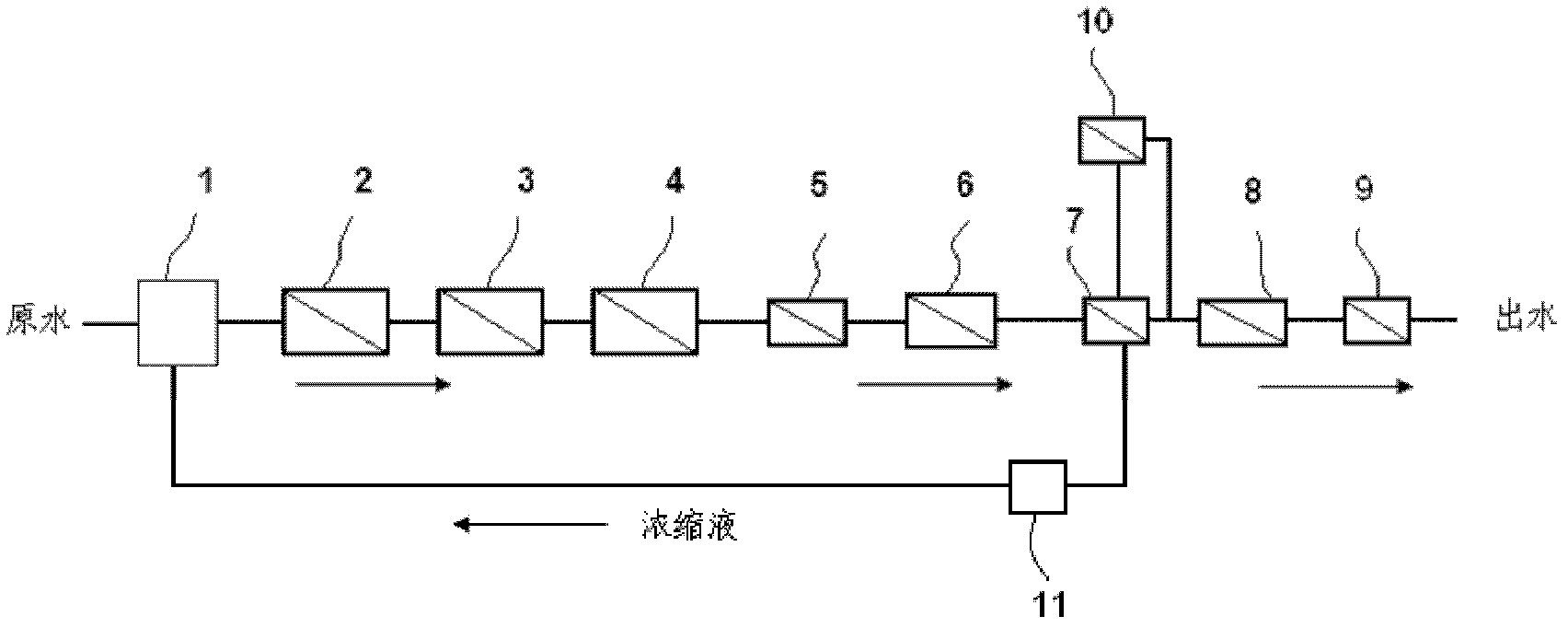

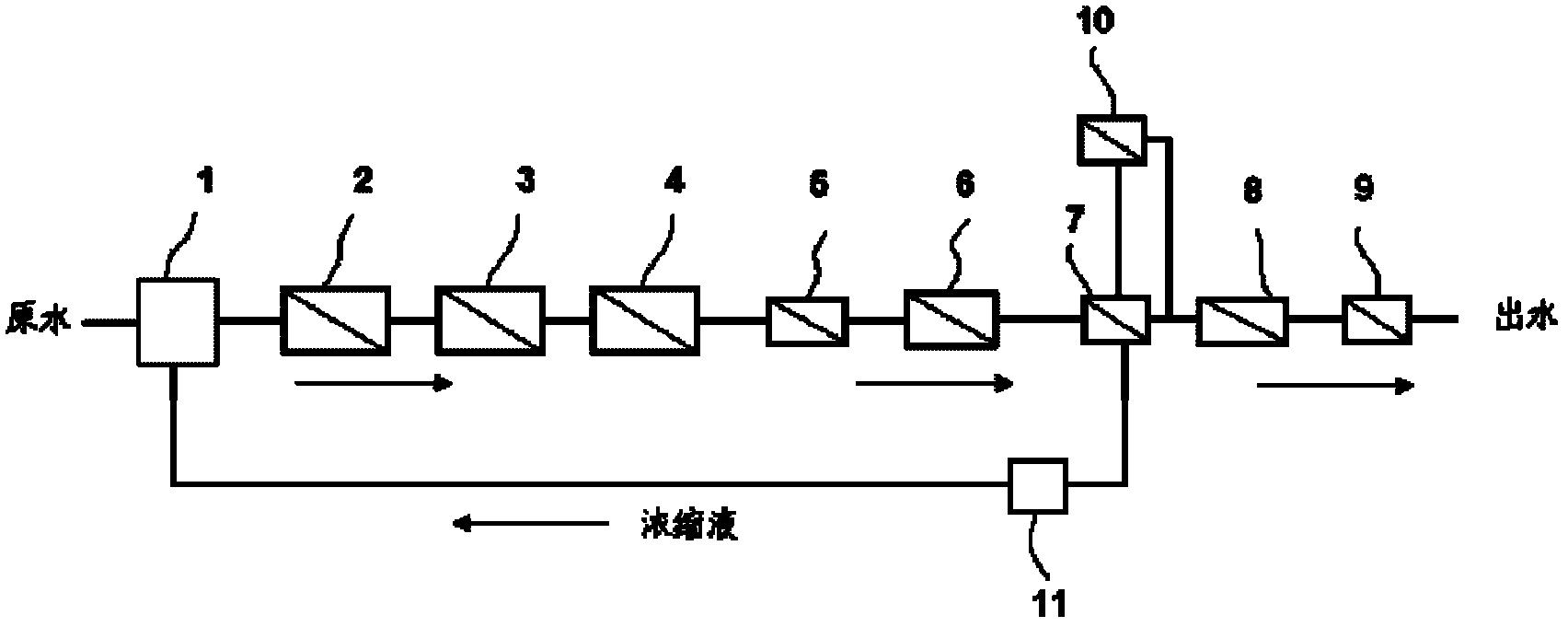

[0058] This embodiment provides a treatment system for the leachate of a comprehensive garbage disposal site, see figure 1 , the system includes: regulating tank (may include supporting auxiliary facilities), coagulation sedimentation tank, upflow anaerobic sludge bed reaction tank, primary anoxic and aerobic membrane bioreactor, advanced oxidation treatment equipment, secondary Anoxic and aerobic membrane bioreactor, nanofiltration membrane treatment equipment (NF), ozone contact tank and activated carbon filter tower, also including reverse osmosis membrane treatment equipment (RO) (rolled reverse osmosis membrane system can be used) and slaked lime mixed sedimentation pool;

[0059] Among them, regulating tank and auxiliary facilities, coagulation sedimentation tank, upflow anaerobic sludge bed reaction tank, first-level anoxic-aerobic membrane bioreactor, advanced oxidation treatment equipment, and second-level anoxic-aerobic membrane bioreactor , nanofiltration membrane ...

Embodiment 2

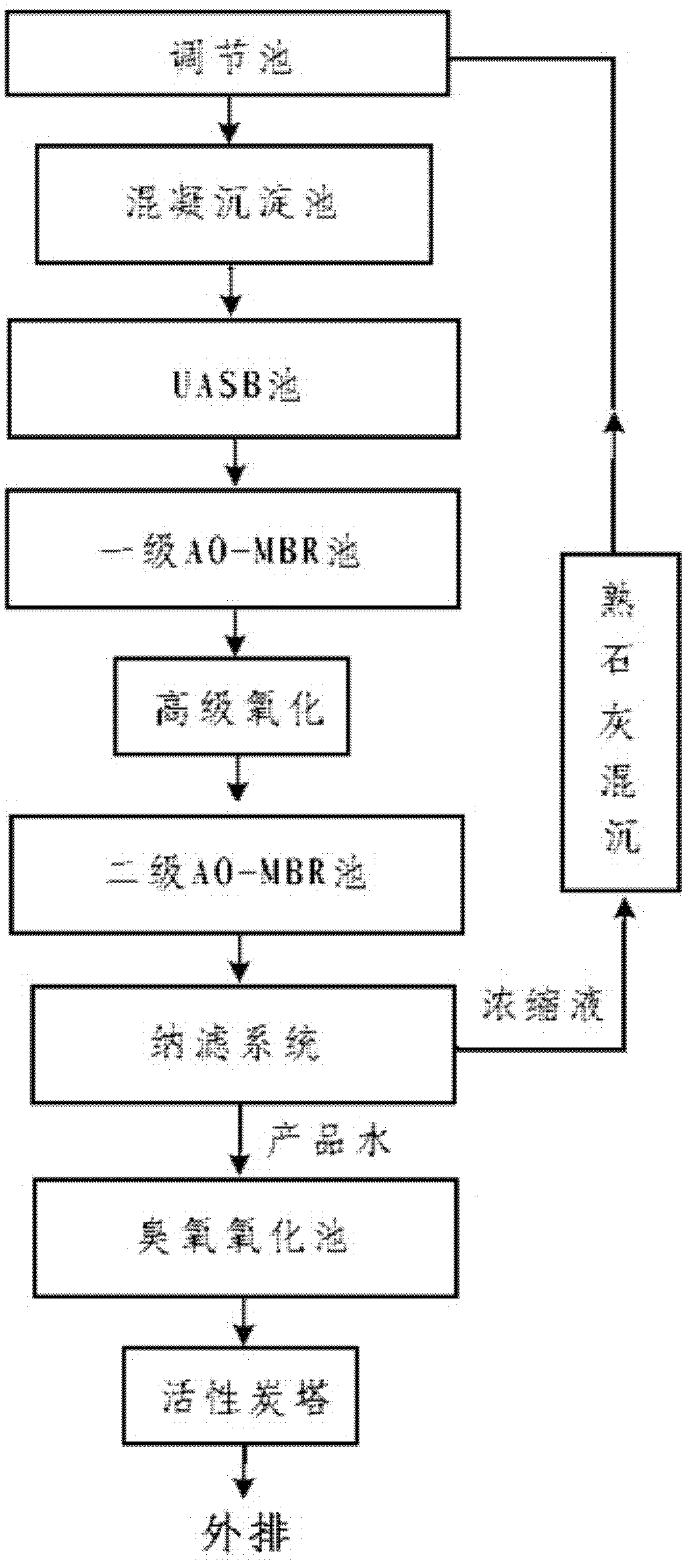

[0067] This embodiment provides a treatment method for the leachate of a comprehensive garbage disposal site. The treatment system provided in the above-mentioned embodiment 1 can be used to carry out advanced treatment of the leachate of a landfill or an incineration plant, such as figure 2 As shown, the method includes:

[0068] Conditioning treatment: Mix the treated landfill leachate evenly, so that the concentration of pollutants in the leachate after mixing is uniform, and carry out coagulation and sedimentation treatment on the effluent after the conditioning treatment;

[0069] Coagulation and sedimentation treatment: Coagulation treatment is carried out on the above-mentioned adjusted leachate. During the coagulation treatment process, coagulant and coagulant aid are added, and after coagulation treatment, precipitation is carried out to remove most of the suspended particles in the landfill leachate. , performing anaerobic biochemical treatment on the effluent after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com