Process method for treating hardly-biodegradable organic wastewater

A technology of organic wastewater and process methods, applied in chemical instruments and methods, light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of incomplete treatment of refractory compounds, a large amount of iron-containing sludge, and discharge that cannot fully meet the standards and other issues, to achieve the effect of reducing the generation of chemical sludge, technical improvement, and efficient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

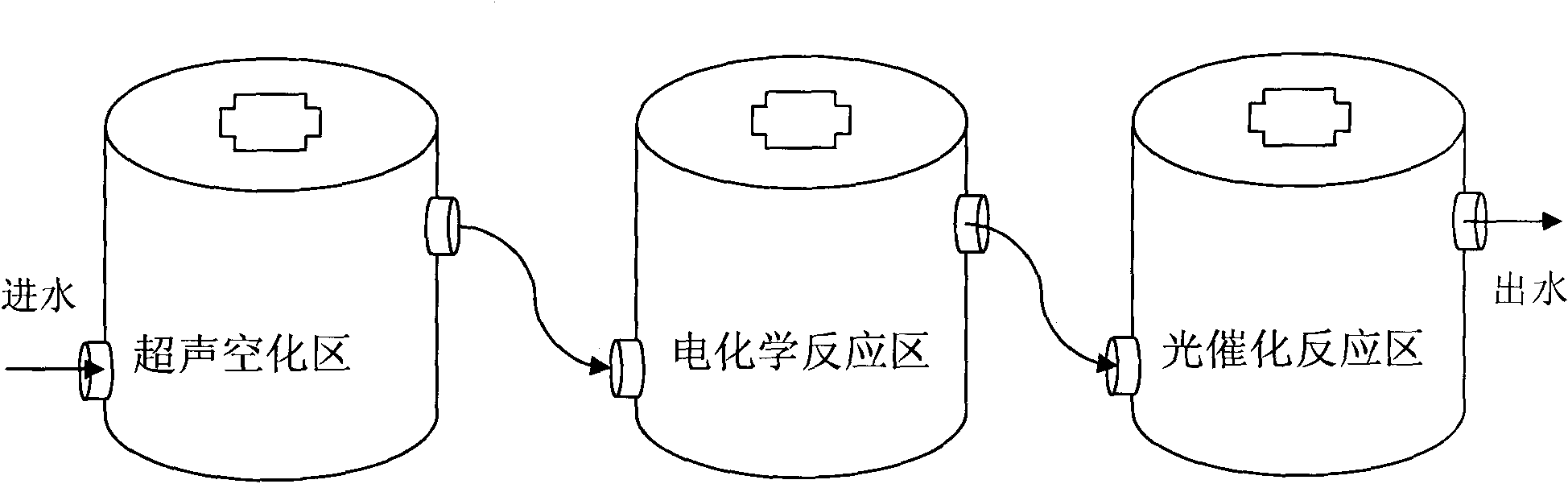

[0051] The COD content of bagasse waste water after physical, chemical and biochemical treatment in the early stage is 2675ml / g. The waste water enters the ultrasonic cavitation process area first. At the bottom of the ultrasonic cavitation process area, an ultrasonic transmitter with a power of 1KW per 1 cubic meter of wastewater treatment volume is installed. The operating frequency is 20KHz. Through the action of the ultrasonic generator, an ultrasonic cavitation area is generated inside the reactor. During ultrasonic cavitation The cavitation process in the region can concentrate the energy of the sound field, and when the cavitation bubble collapses, the highly concentrated energy is released in a very small space in the liquid, forming a local high temperature greater than 5000K and a high pressure greater than 50MPa, and Extreme conditions such as strong shock waves and jets can effectively decompose organic macromolecular compounds into small molecules that are easy to...

Embodiment 2

[0056] The COD content of bagasse waste water after physical, chemical and biochemical treatment in the early stage is 2800ml / g. The waste water enters the ultrasonic cavitation process area first. At the bottom of the ultrasonic cavitation process area, an ultrasonic transmitter with a power of 1KW per 1 cubic meter of wastewater treatment volume is installed. The operating frequency is 80KHz. Through the action of the ultrasonic generator, an ultrasonic cavitation area is generated inside the reactor. During ultrasonic cavitation The cavitation process in the region can concentrate the energy of the sound field, and at the moment of the collapse of the cavitation bubble, the highly concentrated energy is released in a very small space in the liquid, forming a local high temperature greater than 5500°C and a high pressure greater than 55MPa. And extreme conditions such as strong shock waves and jets can effectively decompose organic macromolecular compounds into small molecul...

Embodiment 3

[0061] The COD content of the molasses wastewater from the sugar factory after physicochemical and biochemical treatment in the early stage is 4112ml / g.

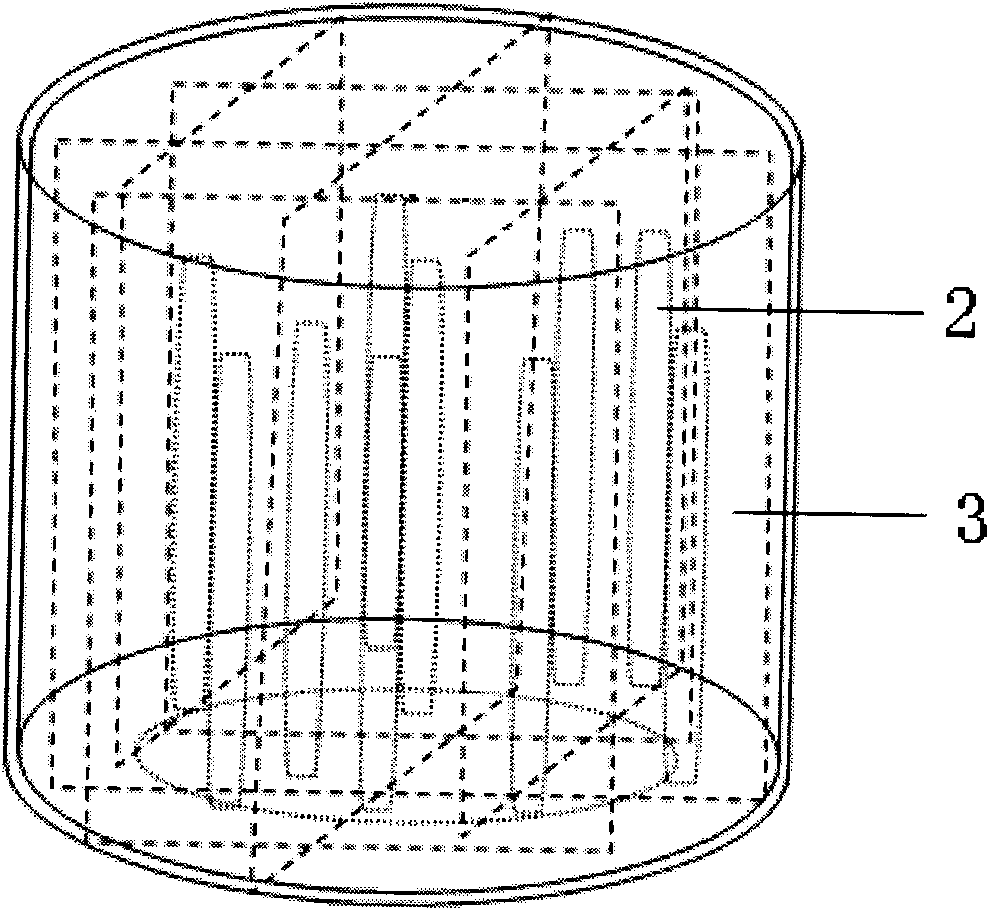

[0062] Firstly, the waste water flows into the circulating electrochemical reaction zone. The cathode of the reaction zone is an electrolytic chamber surrounded by stainless steel plates, and the ratio of the perimeter to the height of each electrolytic chamber is 2:10; the anode is a cylindrical pure iron rod; the ratio of the working area of the cathode to the anode is 8:3. In this reaction zone, Fe is produced by electrochemical means through the anode 3+ / Fe 2+ And convert dissolved oxygen into oxidant H by electrochemical method 2 o 2 It constitutes the components of Fenton reagent, and the current density is controlled at 17-20mA / cm 2 In the range of Fe 3+ / Fe 2+ The concentration is about 11mmol / L.

[0063] The electrochemically treated wastewater enters the ultrasonic cavitation process area. At the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com