Novel water-based adhesives for industrial applications

A water-based adhesive, technology for industrial applications, used in adhesives, protein adhesives, starch adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] [041] For the preparation of reference adhesive Ref 1, a total of 252 g of water was weighed in a 400 ml plastic jar and stirred at 600-700 rpm using a standard laboratory mixer fitted with a 55 mm wide stirring blade. 48g starch powder (Solvicol GP 45 Plus * , from Avebe) was slowly added at a steady rate to a vortex of water. After the powder addition was complete, the mixture was stirred for a total of one hour.

[0045] [042] For the preparation of adhesives Adh 1a and 1b, the above steps were repeated using only 244.5 g of water. Five minutes after the starch addition was complete, water redispersible polymer powder (7.5 g) was added slowly. Pocket and grit formation was not observed.

[0046] Table 1: Using pure water-soluble polymer powder (Ref 1) based Cure speed, tack and machine speed of the adhesive to bond kraft paper to kraft paper.

[0047] Ref 1

Adh 1a

Adh 1b

water [parts]

84

81.5

81.5

WSPP[parts] a...

Embodiment 2

[0060] [045] The reference adhesive Ref2 was prepared similarly to Adh 1a and 1b, but using the amounts mentioned in Table 2 and replacing the water-redispersible polymer powder with a liquid adhesive (Forbo Ulitex 34785).

[0061] [046] Adhesives Adh 2a, 2b and 2c were prepared similarly to Adh 1a and 1b, but using the amounts mentioned in Table 2. Small lumps and grit were not observed.

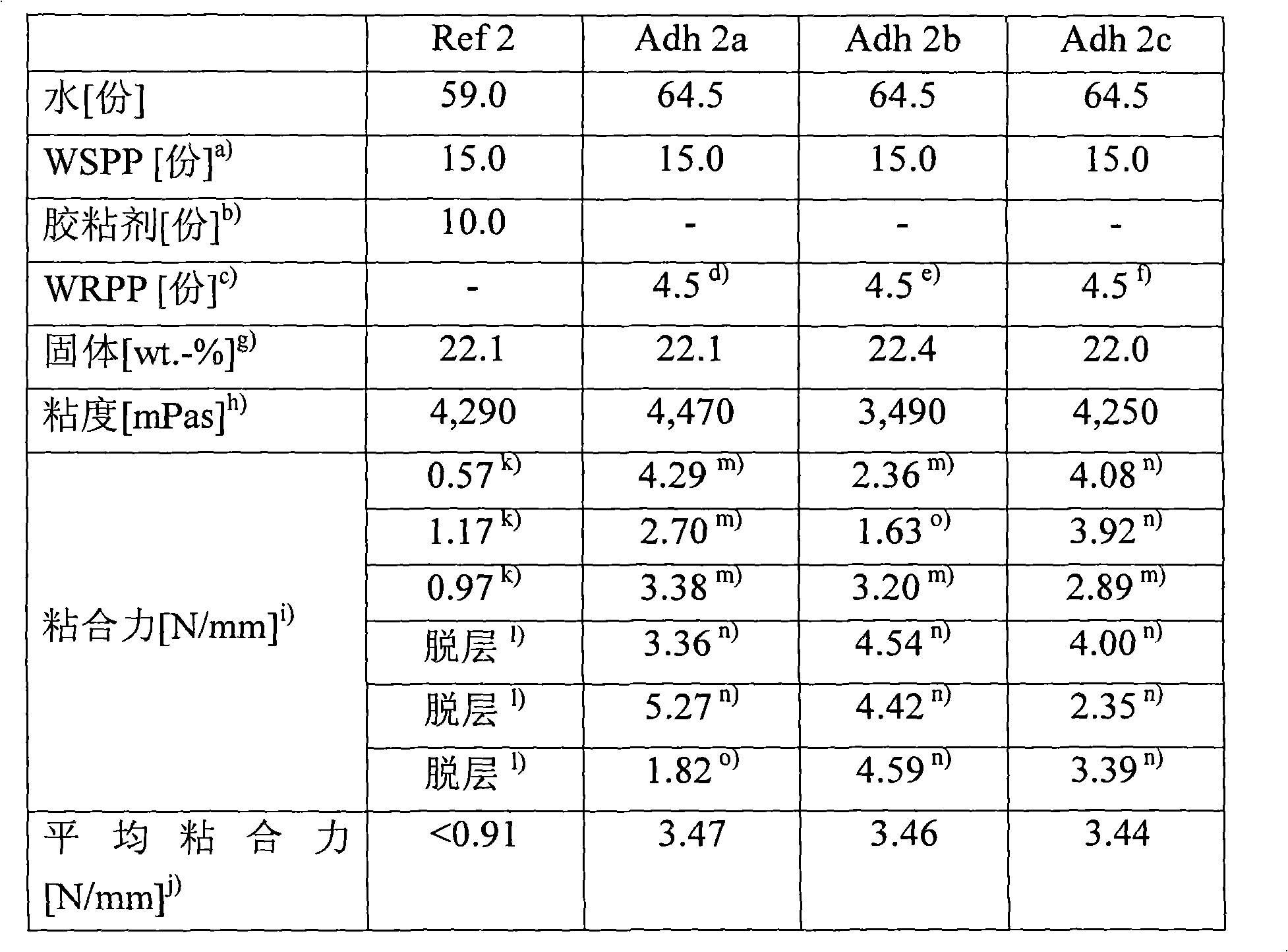

[0062] Table 2: Commercial adhesives based on water soluble polymer powder and liquid emulsion adhesives compared to Adh 2a to Adh 2c where liquid adhesive was replaced by water redispersible polymer powder (same solids content) (Ref 2), Adhesion of kraft paper bonded to polyethylene coated paper with a surface tension of 36 dynes / cm.

[0063]

[0064] a) Water soluble polymer powder (WSPP) is cold water soluble, pregelatinized and hydrolyzed potato starch (Solvicol GP 45 Plus * , from Avebe).

[0065] b) The liquid emulsion adhesive is a commercial polymer dispersion based adhesive g...

Embodiment 3

[0081] [049] Reference adhesive Ref3a was a commercial adhesive and was applied as such. Adhesives Ref 3b and 3c are water-based emulsion polymers adjusted to the stated solids and viscosities, see Table 3, footnotes b) and c). Adhesives Adh 3a and 3b were prepared similarly to Adh 1a and 1b using the relative amounts given in Table 3.

[0082] Table 3: High Density Bonded with Commercial High Performance Water Dispersion Based Adhesive Grades Compared to Synthetic Polymer Dispersions and Mixtures of Water Based Polymer Powder (Starch) and Water Redispersible Polymer Powder Adhesion values for polyethylene (HDPE) sheets - with a surface tension of 36 dyne / cm - and kraft paper.

[0083] Ref3a a)

Ref

3b b)

Ref

3c c)

Adh 3a

Adh 3b

water [parts]

-

-

-

59

59

WSPP[parts] d)

-

-

-

10

10

WRPP [part] e)

-

-

-

38 f)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com