Method for preparing high-conductivity slurry from doped graphene

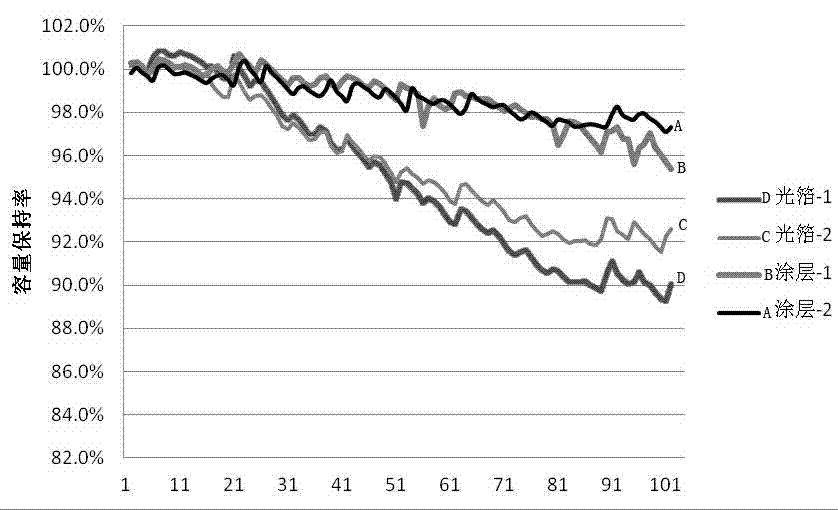

A technology of conductive paste and graphene, which is applied to the manufacture of conductive materials, circuits, and electrodes dispersed in non-conductive inorganic materials, can solve problems such as poor electrical conductivity, achieve good processing performance, reduce coating thickness, and ensure safety good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 100g of conductive paste, 5g of graphene, 4g of dispersant (pvp), and 700g of deionized water. The total weight is 809g, and the initial calculated solid content is 4.69% for use. The described conductive paste is selected from the existing Henkel series conductive paste with a solid content of 29%. In the implementation process, the conductive paste of the Japanese Showa SDX series can also be selected, or one of the Henkel series and the Japanese Showa SDX series. A mixture of one or more conductive pastes.

[0024] That is, the mass ratios of conductive paste: graphene: dispersant: deionized water are: 100: 5: 4: 700, respectively.

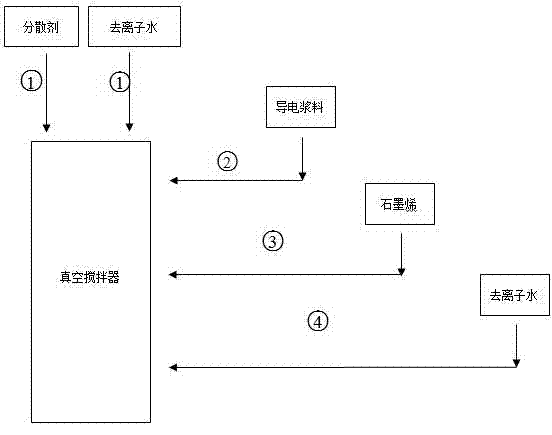

[0025] The mixing steps are:

[0026] Firstly, pour 4g of dispersant (pvp) and 350g of deionized water into a vacuum mixer for mixing, first rotate at a revolution of 20±3r / min, and rotate at a slow speed of 400±20r / min until the dispersant is completely infiltrated. In deionized water, then evacuate to -0.1mpa, and stir rapidly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com