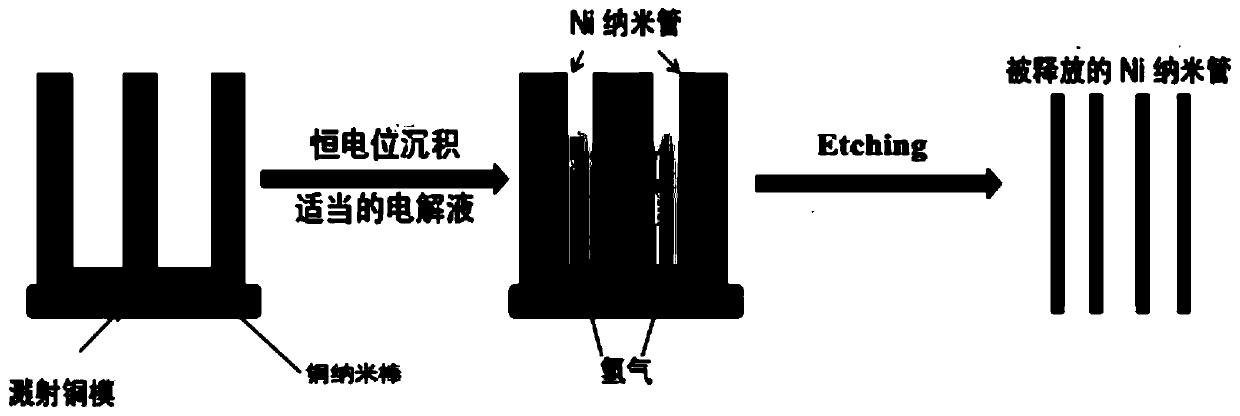

Method for preparing magnetic metal nanotubes by controlling electrodeposition conditions

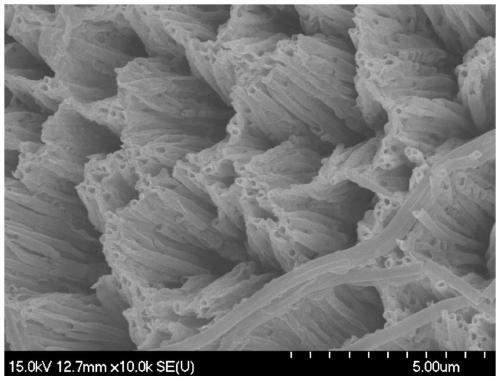

A magnetic metal nano and electrodeposition technology, which is applied in the direction of nanotechnology, nanotechnology, metal material coating technology, etc., can solve the problems of affecting material performance, poor regularity, poor uniformity, etc., to achieve increased generation rate, good regularity, Good uniformity of length and wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] (b-1) Preparation of salt bridge: 95-105 parts by weight of distilled water and 2.5-3.5 parts by weight of agar are added to the container, heated in a water bath until completely dissolved; then 25-35 parts by weight of KCl is added to fully dissolve it, and finally Pour it into a U-shaped thin glass tube while it is hot, and get a salt bridge after the agar solidifies.

[0063] (b-2) Sputtering conductive layer: a layer of copper film is sputtered on the anodized aluminum template: the conditions for sputtering the conductive layer are: the argon flow rate is 10-30 sccm, and the air pressure is 3-5×10 -4 Pa, the self-bias voltage is 150-200Pa. After copper plating, place the electrolyte and anodized aluminum template under a nitrogen atmosphere for 1-3 hours, and then deposit a layer of Cu nanorods on the bottom channel of the anodized aluminum template in the Cu electrodeposition solution. The deposition conditions are: voltage 0.7-0.9V, time 8-12min; component conc...

Embodiment 1

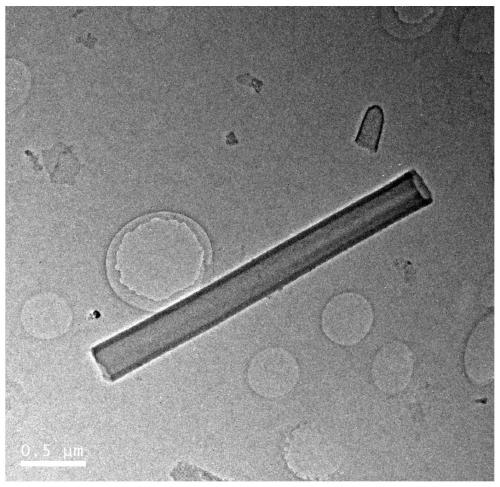

[0074] Embodiment 1 (magnetic metal Ni nanotube)

[0075] (1) Template preparation

[0076] (1-1) Select high-quality and high-purity (purity 99.999%) aluminum sheets and anneal at 500°C for 4 hours, then sonicate in acetone for 10 minutes, then soak in 5% (wt) sodium hydroxide for 5 minutes, and finally Sonicate in acetone for 3 minutes to complete the pretreatment of the aluminum sheet.

[0077] (1-2) The first oxidation: corrode the pretreated aluminum sheet at 40V voltage and 0°C for 4 hours, and the electrolyte concentration is 0.3mol / L oxalic acid.

[0078] (1-3) Removal of the primary oxide film: After taking it out, soak it in a mixed solution of 65°C, 6% (wt) phosphoric acid and 1.5% (wt) chromic acid for 12 hours to remove the primary oxide film, and clean it with deionized water .

[0079](1-4) Second oxidation: place the aluminum sheet from which the primary oxide film has been removed in 0.3mol / L oxalic acid aqueous solution, electrochemically corrode it for 8 ...

Embodiment 2

[0087] Embodiment 2 (magnetic metal Fe nanotube)

[0088] (1) Template preparation

[0089] (1-1) Select high-quality and high-purity (purity 99.999%) aluminum sheets and anneal at 500°C for 4 hours, then sonicate in acetone for 10 minutes, then soak in 5% (wt) sodium hydroxide for 5 minutes, and finally Sonicate in acetone for 3 minutes to complete the pretreatment of the aluminum sheet.

[0090] (1-2) The first oxidation: corrode the pretreated aluminum sheet at 40V voltage and 0°C for 4 hours, and the electrolyte concentration is 0.3mol / L oxalic acid.

[0091] (1-3) Removal of the primary oxide film: After taking it out, soak it in a mixed solution of 65°C, 6% (wt) phosphoric acid and 1.5% (wt) chromic acid for 12 hours to remove the primary oxide film, and clean it with deionized water .

[0092] (1-4) Second oxidation: place the aluminum sheet from which the primary oxide film has been removed in 0.3mol / L oxalic acid aqueous solution, electrochemically corrode it for 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com