Transparent electrode and method for producing same

A transparent electrode, transparent conductivity technology, applied in transparent dielectric, printed circuit manufacturing, cable/conductor manufacturing, etc., can solve problems such as unfavorable productivity and increased manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

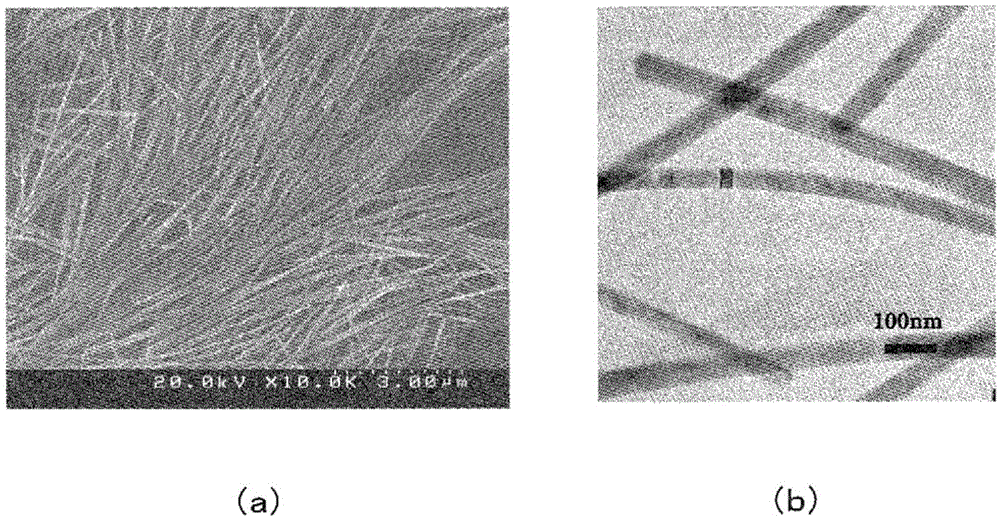

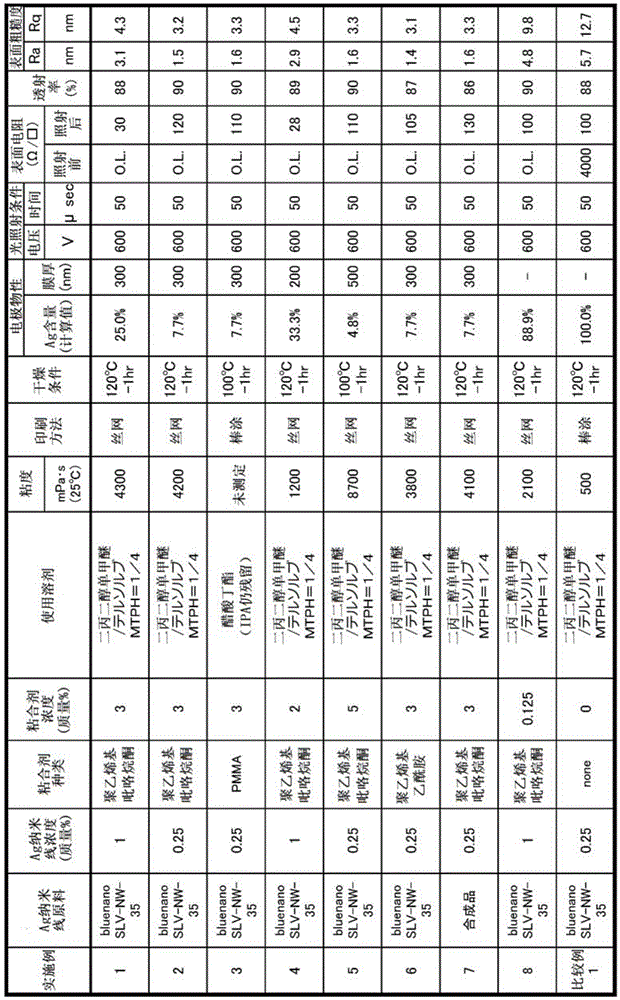

[0083] When preparing transparent conductive ink, use commercially available silver nanowire dispersion liquid SLV-NW-35 (isopropyl alcohol dispersion liquid manufactured by bluenano company, concentration 10mg / mL, silver nanowire diameter 35nm, length about 15μm (catalogue value) )) as raw material. To 25 mL of the silver nanowire dispersion liquid, 0.75 g of polyvinylpyrrolidone (manufactured by Nippon Shokubai) dissolved in 4.8 g of dipropylene glycol monomethyl ether (purchased as a reagent from Kanto Chemical Co., Ltd.) was added at room temperature. g solution, after mixing, the isopropanol was distilled off and the solvent was replaced. After that, 19.2 g of Terusolbu MTPH (Isobornylcyclohexanol manufactured by Nippon Terupen Chemical Co., Ltd.) was added, and stirred at a rotation speed of 1200 rpm for 3 hours using a rotation and revolution vacuum mixer Awatori Rentaro ARV-310 manufactured by Shinki Corporation. minutes, a transparent conductive ink having a concentr...

Embodiment 2~6、8

[0085] Except changing the concentration of the dipropylene glycol monomethyl ether solution of polyvinylpyrrolidone and the amount of tersolub MTPH added to 25 mL of SLV-NW-35, the same operations as in Example 1 were carried out, respectively.

Embodiment 7

[0087] The ethanol dispersion of silver nanowires obtained by the above synthesis was used as a raw material. A transparent conductive ink was prepared in the same manner as in Example 1 using SLV-NW-35 except that the dispersion solvent was ethanol and the concentration was 0.2% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com