Method for preparing magnetic metal nanotubes through pulse electrodeposition

A magnetic metal nanometer and pulse electrodeposition technology, which is applied in nanotechnology, metal material coating process, electrolytic coating, etc., can solve the problems of inability to prepare high-quality magnetic metal nanotubes, the inability to control the length and diameter of nanotubes, etc. Achieve the effect of being conducive to mass production preparation, low cost and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

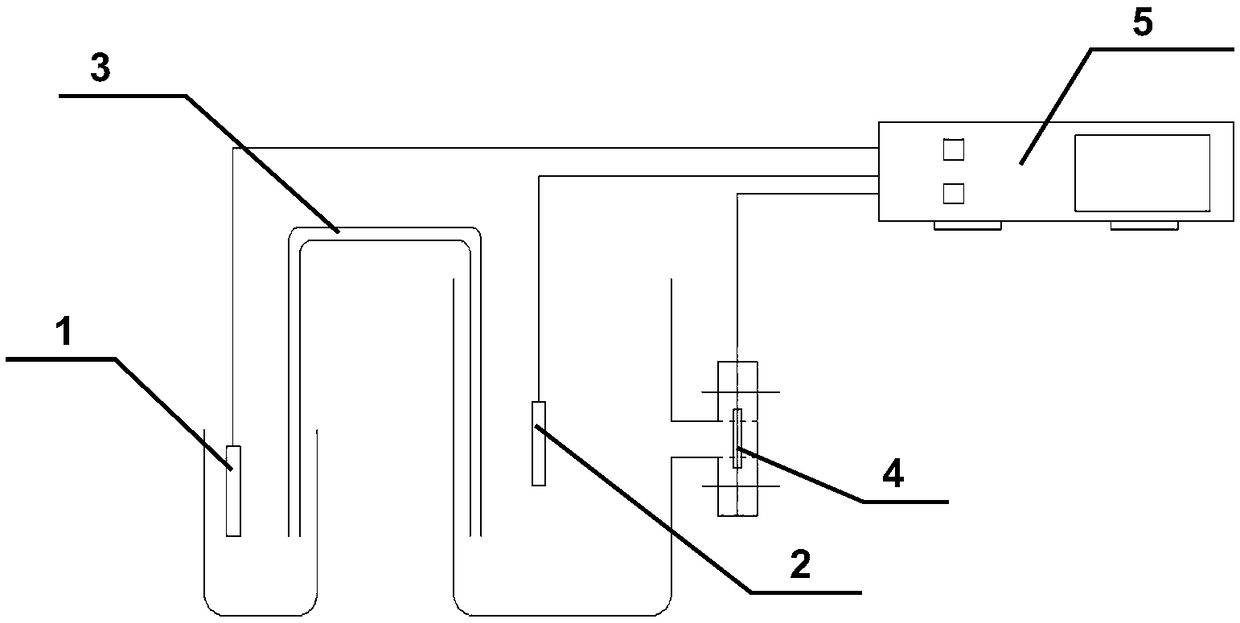

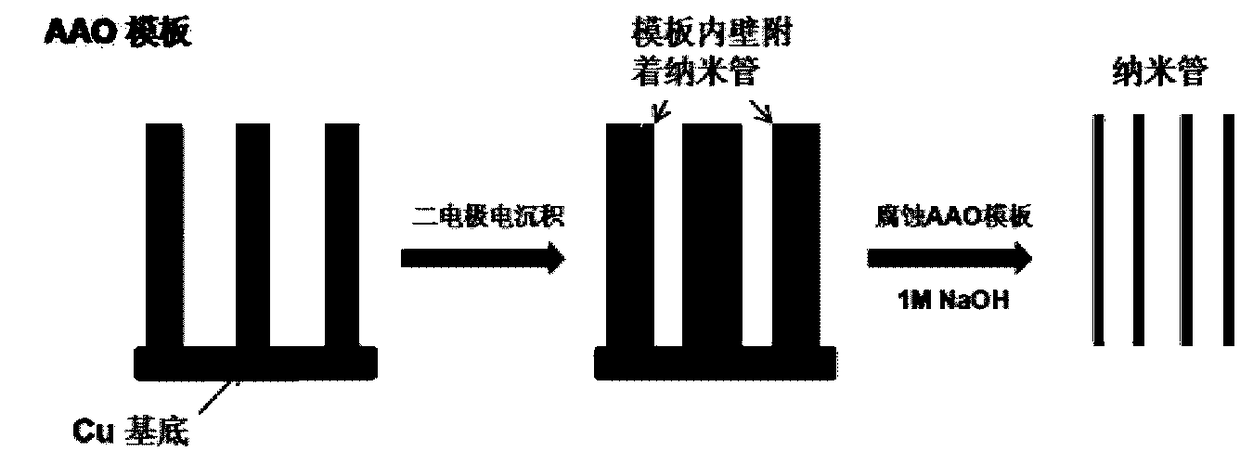

[0046] A method for preparing magnetic metal nanotubes by pulse electrodeposition, the method for preparing magnetic metal nanotubes by pulse electrodeposition comprises the following steps:

[0047] (a) Template preparation

[0048] (a-1) Primary oxidation: anneal the aluminum sheet at 500°C for 4 hours, then sonicate in acetone for 10 minutes, then soak in 5wt% sodium hydroxide aqueous solution for 5 minutes, sonicate in acetone for 3 minutes, and then The treated aluminum sheet is placed in 0.3mol / L oxalic acid aqueous solution, and electrochemically corroded for 4 hours at a voltage of 40V and a temperature of 0°C to obtain a primary alumina sheet;

[0049] (a-2) Removing the primary oxide film: take the primary alumina sheet prepared in step (a-1), and place it in a mixed aqueous solution of phosphoric acid and chromic acid with a phosphoric acid concentration of 6 wt% and a chromic acid concentration of 1.5 wt% at 65°C Soak in the middle for 12h, and then clean it with ...

Embodiment 2

[0059] A method for preparing magnetic metal nanotubes by pulse electrodeposition, the method for preparing magnetic metal nanotubes by pulse electrodeposition comprises the following steps:

[0060] (a) Template preparation

[0061] (a-1) Primary oxidation: anneal the aluminum sheet at 500°C for 4 hours, then sonicate in acetone for 10 minutes, then soak in 5wt% sodium hydroxide aqueous solution for 5 minutes, sonicate in acetone for 3 minutes, and then The treated aluminum sheet is placed in 0.3mol / L oxalic acid aqueous solution, and electrochemically corroded for 4 hours at a voltage of 40V and a temperature of 0°C to obtain a primary alumina sheet;

[0062] (a-2) Removing the primary oxide film: take the primary alumina sheet prepared in step (a-1), and place it in a mixed aqueous solution of phosphoric acid and chromic acid with a phosphoric acid concentration of 6 wt% and a chromic acid concentration of 1.5 wt% at 65°C Soak in the middle for 12h, and then clean it with ...

Embodiment 3

[0072] A method for preparing magnetic metal nanotubes by pulse electrodeposition, the method for preparing magnetic metal nanotubes by pulse electrodeposition comprises the following steps:

[0073] (a) Template preparation

[0074] (a-1) Primary oxidation: anneal the aluminum sheet at 500°C for 4 hours, then sonicate in acetone for 10 minutes, then soak in 5wt% sodium hydroxide aqueous solution for 5 minutes, sonicate in acetone for 3 minutes, and then The treated aluminum sheet is placed in 0.3mol / L oxalic acid aqueous solution, and electrochemically corroded for 4 hours at a voltage of 40V and a temperature of 0°C to obtain a primary alumina sheet;

[0075] (a-2) Removing the primary oxide film: take the primary alumina sheet prepared in step (a-1), and place it in a mixed aqueous solution of phosphoric acid and chromic acid with a phosphoric acid concentration of 6 wt% and a chromic acid concentration of 1.5 wt% at 65°C Soak in the middle for 12h, and then clean it with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com