Device and process for mass production of nanometer fiber by melt electro-spinning method

A melt electrospinning and mass production technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of increasing the effective distance of electrostatic stretching, low output, thick fibers, etc., and achieve flexibility Arrangement, improved production efficiency, and more consistent diameter effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

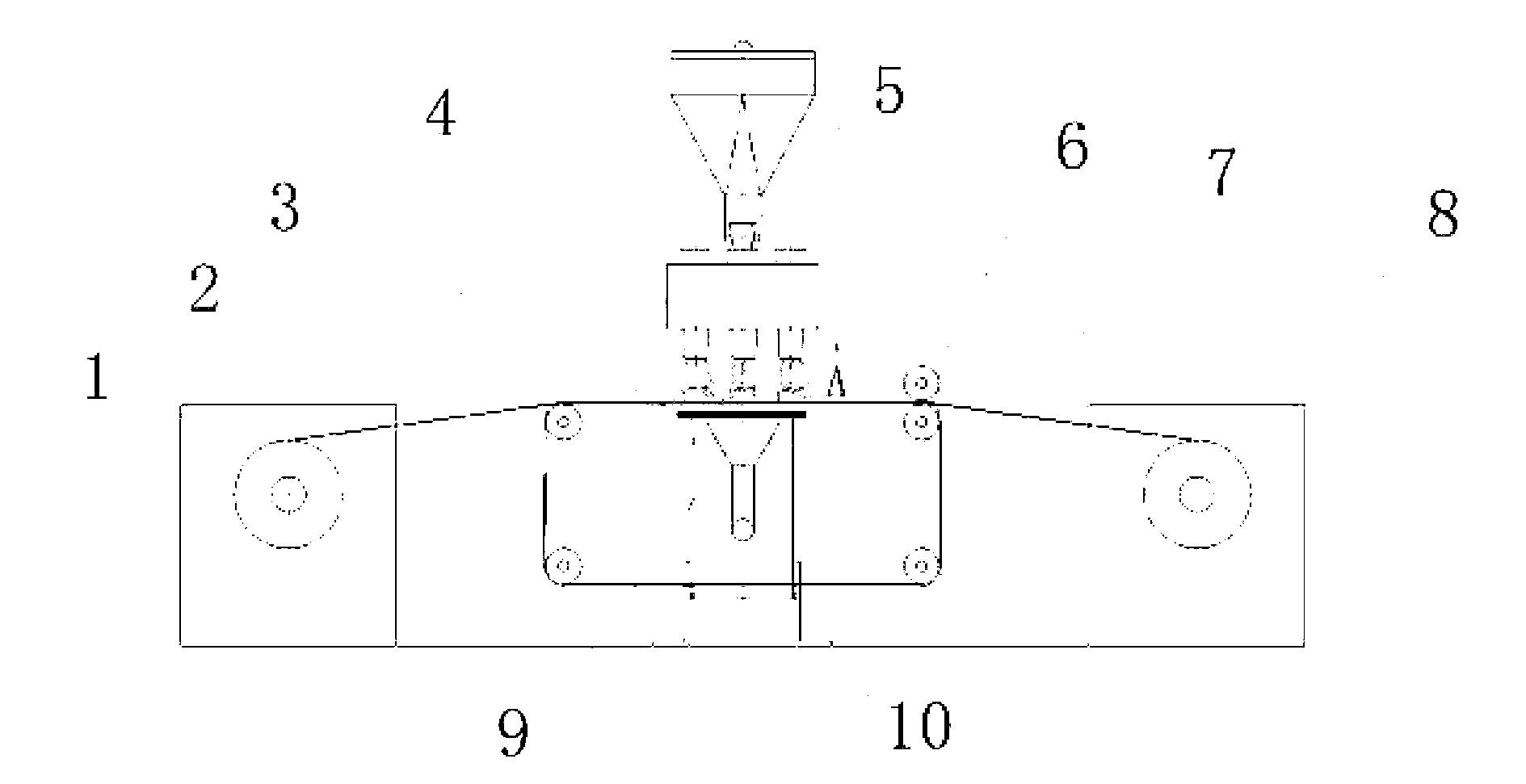

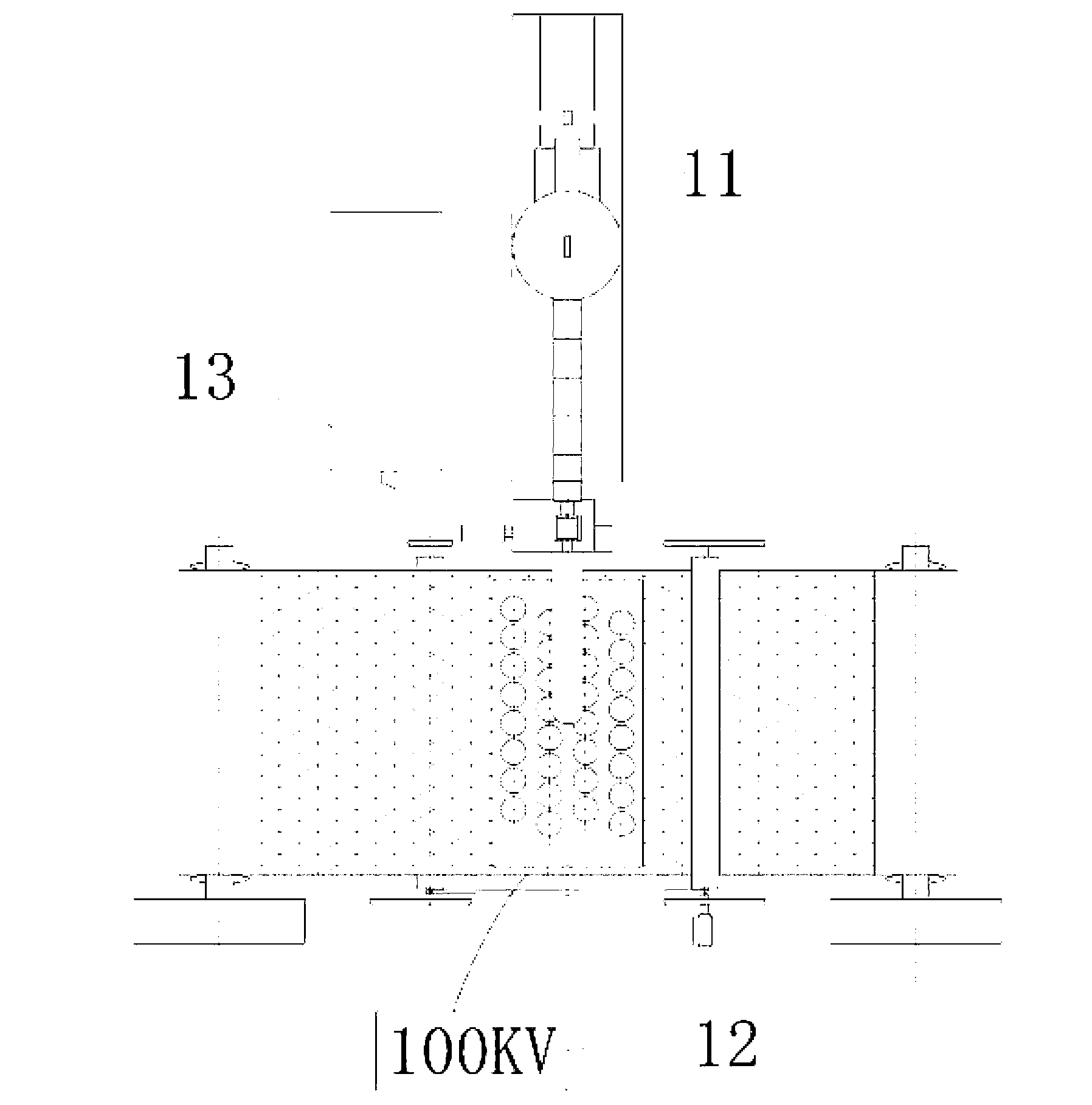

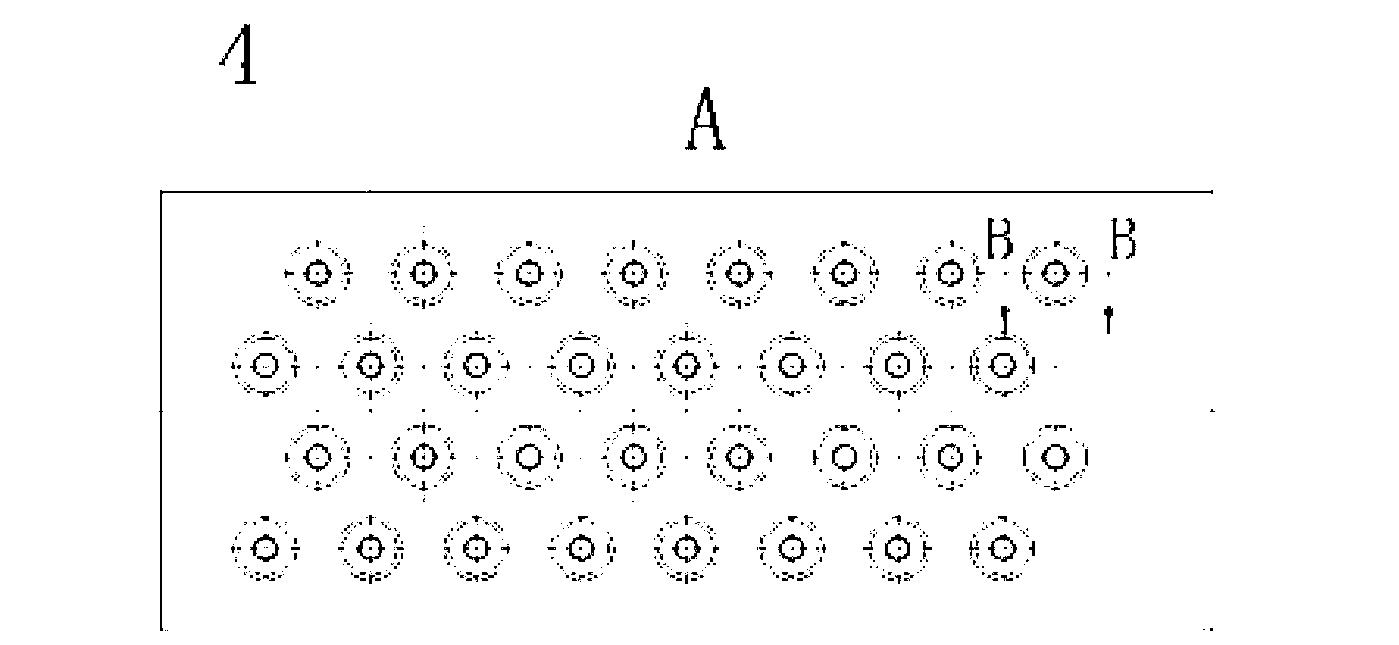

[0030] The melt electrospinning method of the present invention mass-produces nanofiber devices, such as Figure 1-4 As shown, it includes base fabric unwinding device 1, conveyor belt device 2, high voltage electrode net 3, spinning die assembly 4, melt metering pump 5, static removal roller 6, base fabric 7, base fabric winding device 8, hot air Loop 9, electrode grid insulating support 10, melt conveying device 11, high-voltage electrostatic generator 12 and air heating system 13, melt conveying device 11 is directly connected with the inlet of melt metering pump 5, and the outlet of melt metering pump 5 is connected with The melt inlet of the spinning die assembly 4 is connected, the high voltage electrode of the high voltage electrostatic generator 12 is connected with the high voltage electrode network 3 placed under the base cloth, the spinning die assembly 4 is grounded, and the base cloth 7 is connected to the spinning die assembly 4 The fiber is continuously transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com