Bamboo joint-like carbon nano-tube preparation method

A carbon nanotube and bamboo-shaped technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor environmental friendliness, low content of carbon nanotubes, and high cost, and achieve Wide application prospects, easy mass production, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A kind of preparation method of bamboo-shaped carbon nanotube provided by the invention, concrete steps and conditions are as follows:

[0022] 1) Dissolve 0.50-1.00g melamine in ultrapure water;

[0023] 2) Add 5.0-10.0mL of 0.10g / ml surfactant and 5.0-10.0mL of 1.0wt% soluble iron salt in sequence, stir until uniform, and then ultrasonicate for 4-6 hours;

[0024] Described soluble iron salt is ferric nitrate, ferric acetate or ferric chloride;

[0025] Described surfactant is poly(ethylene glycol)-block-poly(propylene glycol)-block-poly(ethylene glycol) (P123) or F127;

[0026] 3) Put the residue obtained in step 2) after drying at 80°C into a quartz boat, program the temperature to 750-900°C under nitrogen protection, and heat-treat for 1-3 hours to obtain bamboo with a diameter of 40-110nm. Nodal carbon nanotubes.

Embodiment 1

[0028] 1) Dissolve 1.00g of melamine in 10mL of ultrapure water;

[0029] 2) Add 5.0mL (0.10g / ml) of poly(ethylene glycol)-block-poly(propylene glycol)-block-poly(ethylene glycol) (P123) and 7.5mL of 1.0wt% ferric nitrate in turn, stir well until uniform, then sonicate for 4 hours;

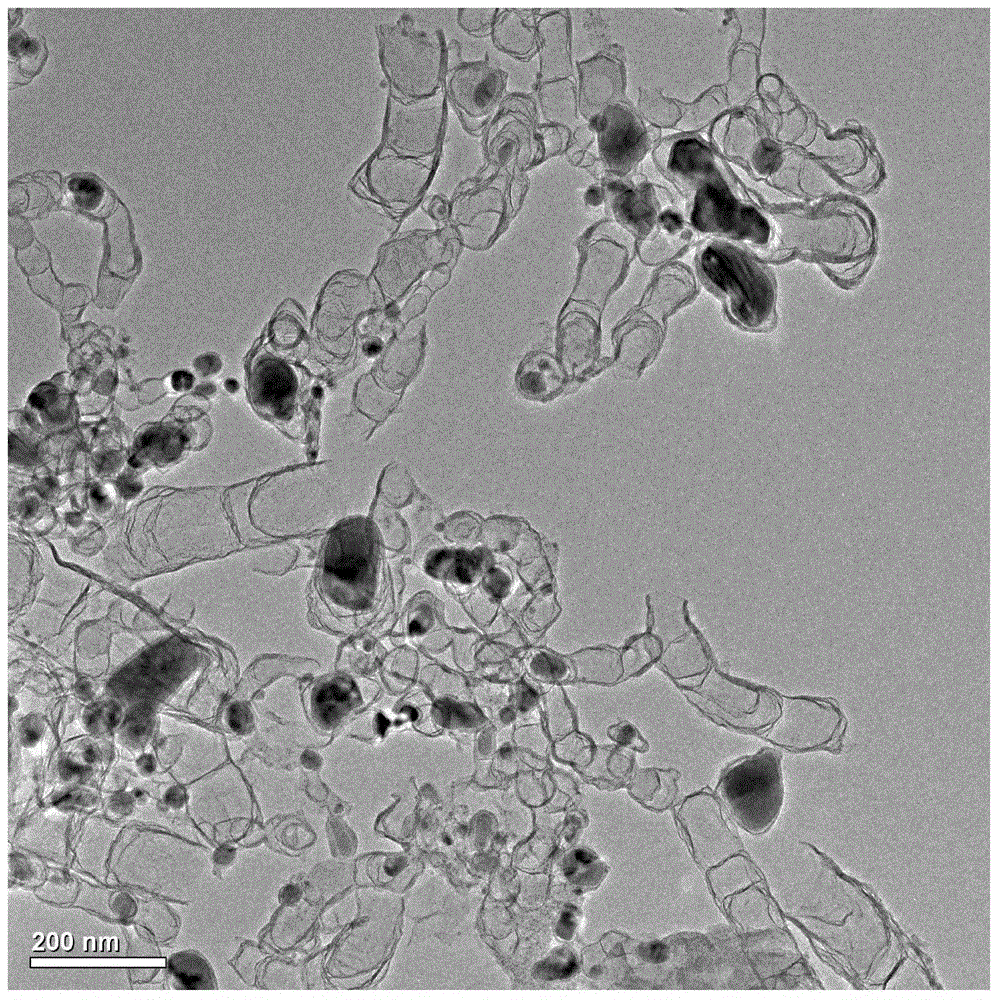

[0030] 3) The residue after drying the above solution at 80°C was put into a quartz boat, and the temperature was programmed to rise to 750°C under the protection of nitrogen, and heat-treated for 3 hours to obtain bamboo-shaped carbon nanotubes. Depend on figure 1 The transmission electron microscope (TEM) picture of the bamboo-shaped carbon nanotubes can be clearly seen, which is a bamboo-shaped carbon nanotube with a diameter of 40-110nm.

Embodiment 2

[0032] 1) Dissolve 0.50g melamine in 10mL ultrapure water;

[0033] 2) Add 7.5mL (0.10g / ml) poly(ethylene glycol)-block-poly(propylene glycol)-block-poly(ethylene glycol) (P123) and 5.0mL 1.0wt% ferric chloride in sequence, fully Stir until uniform, then sonicate for 5 hours;

[0034] 3) The residue after drying the above solution at 80°C was put into a quartz boat, the temperature was programmed to rise to 800°C under the protection of nitrogen, and heat treated for 1 hour to obtain bamboo-shaped carbon nanotubes.

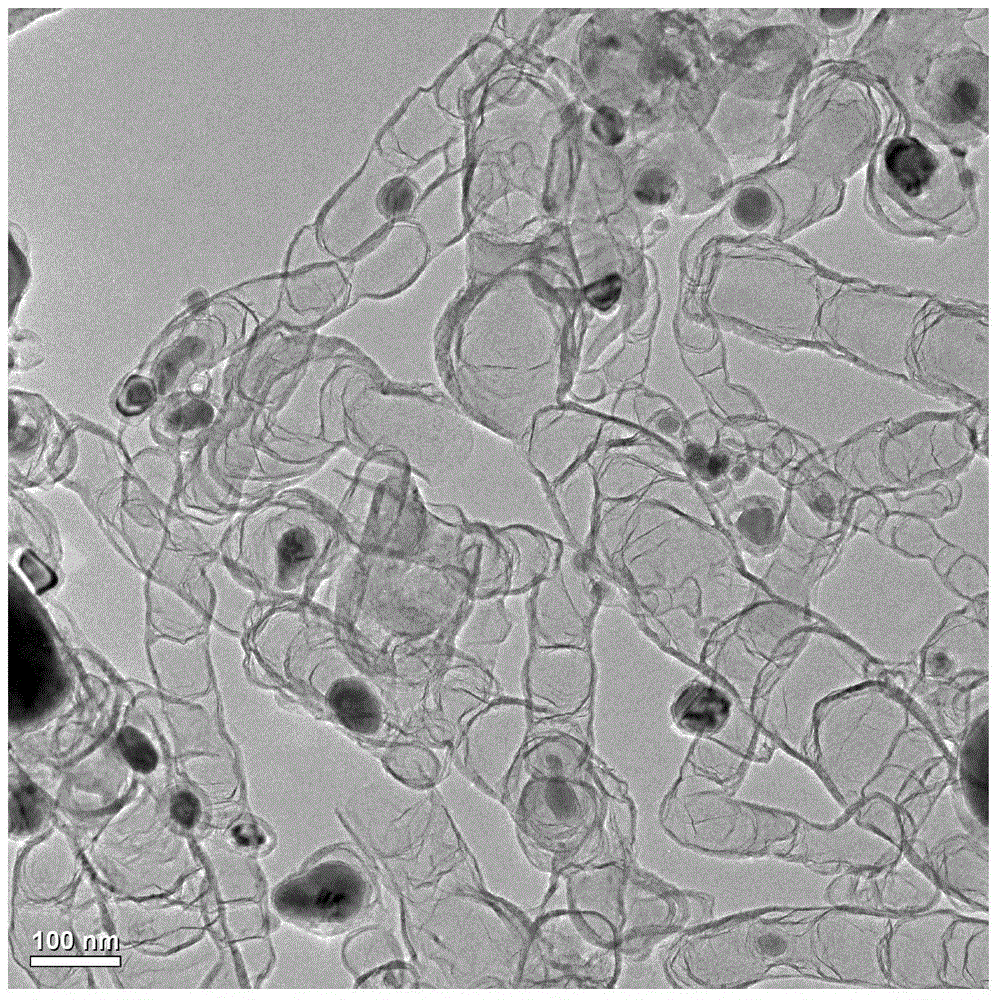

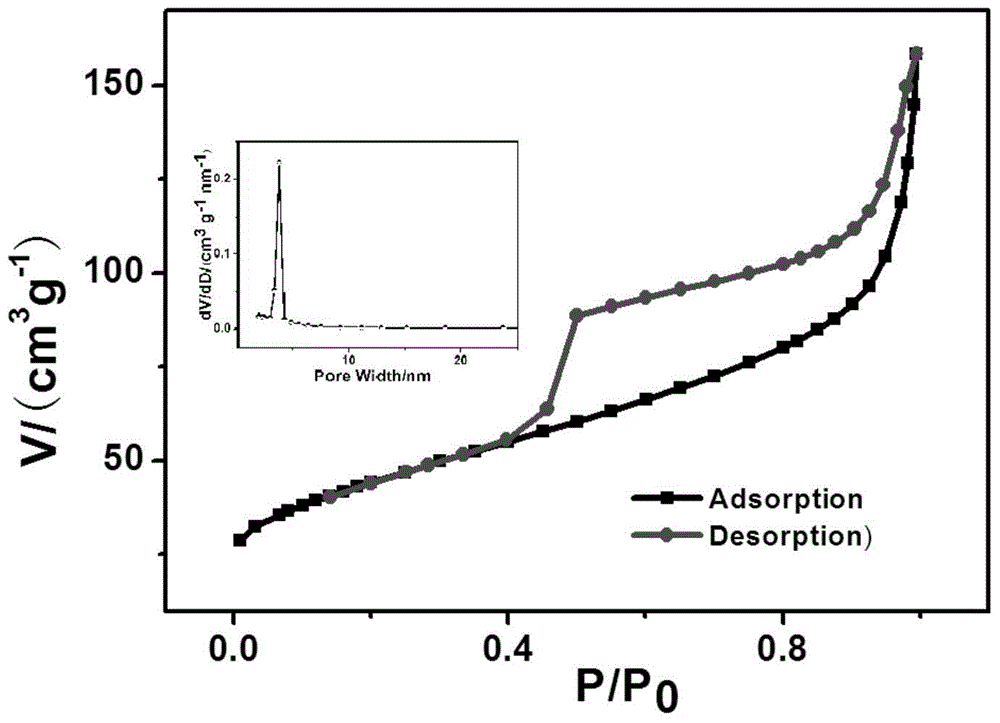

[0035] figure 2 The TEM images show the existence of continuous clear bamboo-shaped carbon nanotubes, and the diameter of bamboo-shaped carbon nanotubes is 40-110nm. we carry out N 2 Adsorption and desorption experiments to study the specific surface area of the material, image 3 The results show that the specific surface area of the material is 151.2m 2 / g, and due to the stacking between carbon nanotubes, a pore structure is formed, with a pore size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com