Preparation for polypyrole coated lithium iron phosphate

A technology for coating lithium iron phosphate and lithium iron phosphate, which is applied in the field of composite material preparation, can solve problems such as high temperature cycle stability of lithium iron phosphate, etc. Good electrical conductivity and electrochemical performance, achieving the effect of industrial scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

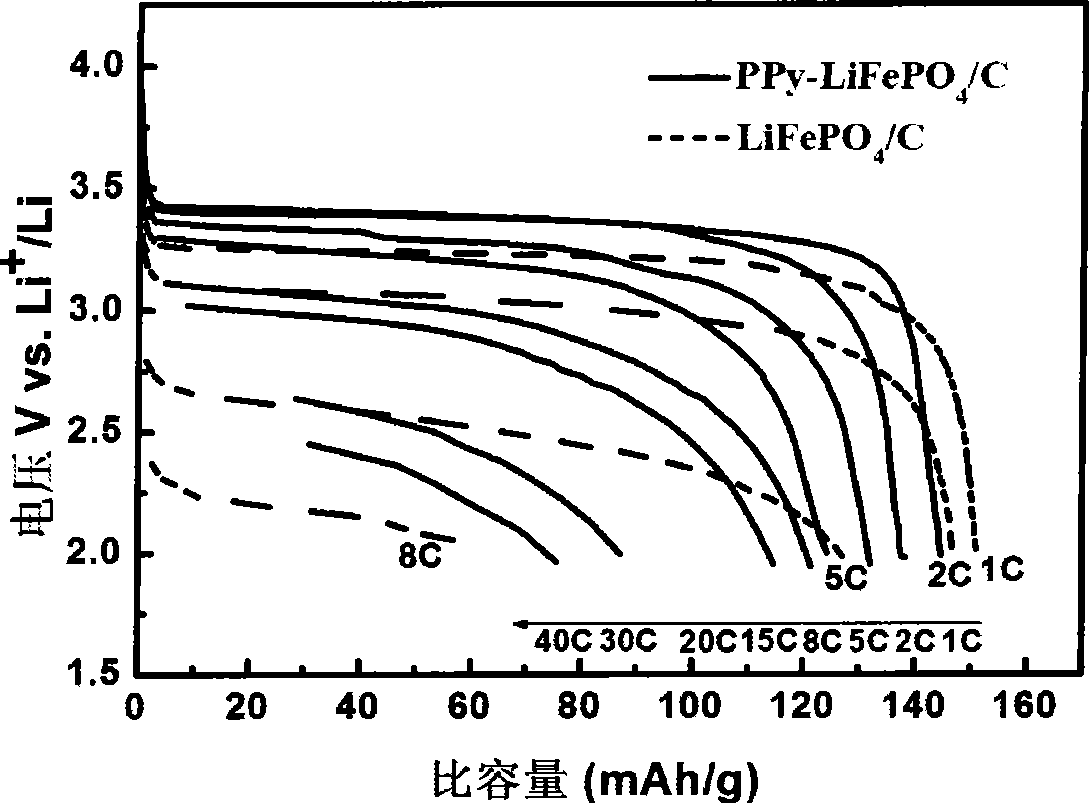

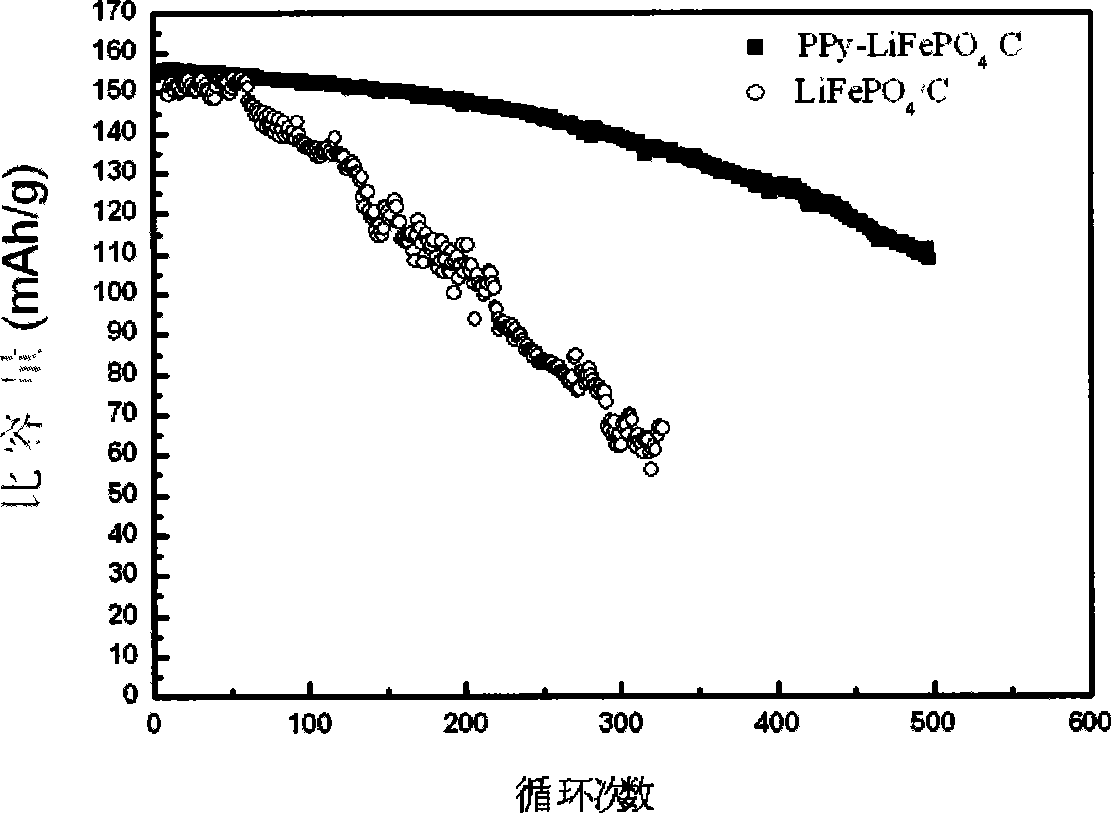

[0015] Weigh 4 grams of iron p-toluenesulfonate hexahydrate and dissolve it in 16 grams of ethanol, then add 2 grams of lithium iron phosphate powder (LiFePO 4 / C, containing 2.4wt% C), ultrasonically dispersed in it, and placed in an ice bath, the temperature was controlled at about 0°C to 4°C, 0.17 g of pyridoxine monomer was added dropwise in the stirring state, and the stirring was continued for 30 minutes to make the pyridoxine The polypyrrone monomer is fully polymerized; the reacted product is centrifuged, washed several times with ethanol, dried, ground and sieved to obtain polypyrrole-coated lithium iron phosphate (PPy-LiFePO 4 / C, containing 5 wt% PPy, 2.4 wt% C).

[0016] Weigh 0.45 g of the prepared PPy-LiFePO 4 / C powder, add 0.09 gram of carbon black and 0.06 gram of polyvinylidene fluoride binder dissolved in N-N' dimethylpyrrolidone, mix evenly and apply it on the aluminum foil to make a positive electrode sheet. In an argon atmosphere drying glove box, with ...

Embodiment 2

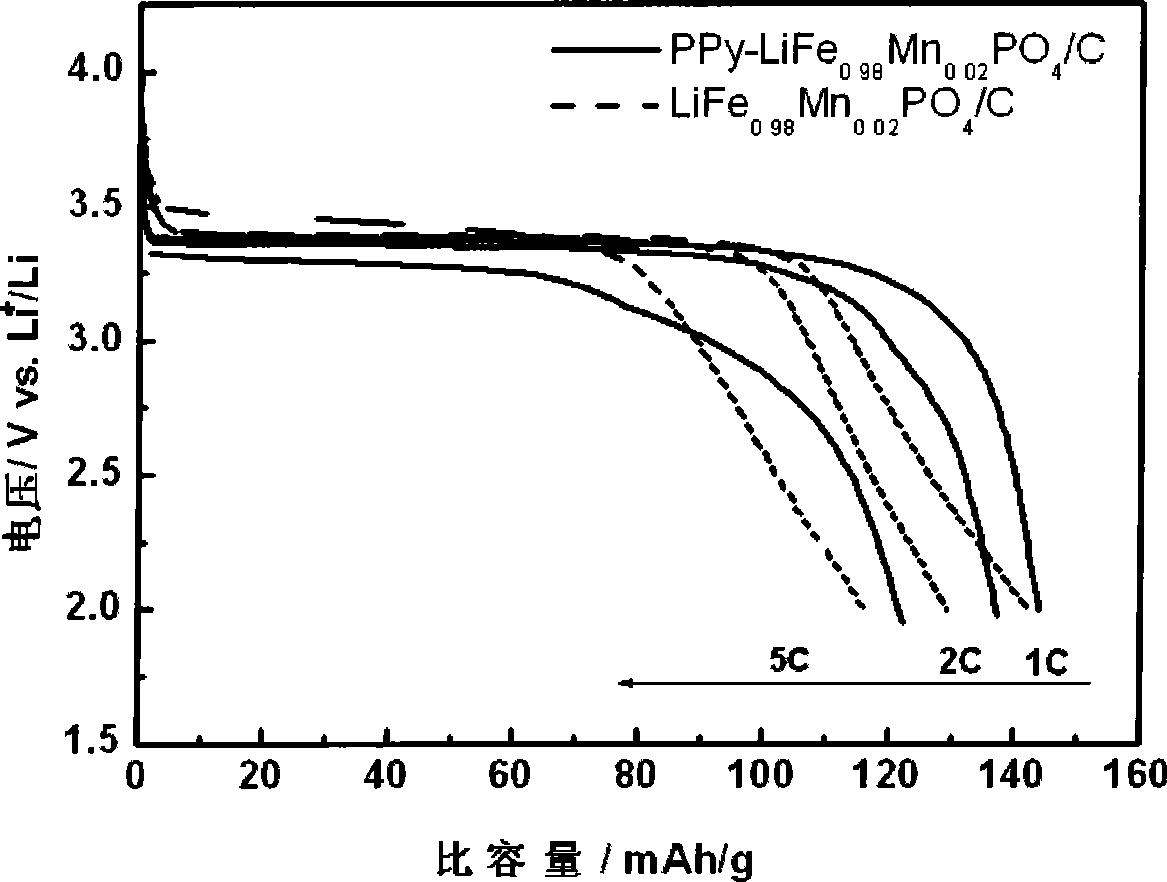

[0019] Weigh 1.5 grams of iron p-toluenesulfonate hexahydrate and dissolve it in 4.5 grams of n-butanol, then add 1 gram of lithium iron phosphate powder LiFe containing trace manganese 0.98 mn 0.02 PO 4 / C (containing 2.7wt% C) was ultrasonically dispersed in it, and placed in an ice bath, the temperature was controlled at about 0°C to 4°C, 0.06 g of pyridoxine monomer was added dropwise in the stirring state, and the stirring was continued for 30 minutes to make the pyridoxine The monomer is fully polymerized. The reacted product was centrifuged, washed several times with ethanol, dried, ground and sieved to obtain polypyrone-coated lithium iron phosphate PPy-LiFe 0.98 mn 0.02 PO 4 / C (containing 2.7wt% C, 3wt% PPy).

[0020] The resulting PPy-LiFe 0.98 mn 0.02 PO 4 / C (containing 2.7wt%C, 3wt%PPy) composite material and LiFe before coating 0.98 mn 0.02 PO 4 / C material is prepared into a battery by the same method as in Example 1 and is compared with high-rate di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com