Preparation method of nano Ni/Fe-biochar composite material and application of nano Ni/Fe-biochar composite material in in-situ restoration of polybrominated diphenyl ether polluted soil

A polybrominated diphenyl ether and composite material technology, applied in the field of environmental pollution control and restoration, can solve the problems of reduced specific surface area and degradation efficiency, easy agglomeration and oxidation, affecting soil fertility, etc., and achieves simple preparation method, short restoration time, Beneficial for recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method of nano-Ni / Fe-biochar composite material includes the following preparation methods:

[0036] 1) Dissolve the iron salt or ferrous salt and polyvinylpyrrolidone in the ethanol aqueous solution, mix well, then add the biochar particles, stir and mix well to obtain solution A;

[0037] 2) Add the ethanol aqueous solution containing the reducing agent to the solution A, after the stirring reaction is complete, the reaction product is separated, washed and added to the ethanol aqueous solution to obtain the solution B;

[0038] 3) Add the nickel salt-containing ethanol aqueous solution dropwise to the solution B, after the stirring reaction is completed, the product material is separated, and the nano-Ni / Fe-biochar composite material is obtained after washing and drying.

[0039] Preferably, the ethanol aqueous solution is a deoxygenated ethanol aqueous solution.

[0040] Preferably, the concentration of ethanol in the ethanol aqueous solution is 20-50% v / v.

[00...

Embodiment 1

[0062] Example 1 Preparation method of nano bimetallic nickel-iron solid particles

[0063] (1) Dissolve the ferrous salt and polyvinylpyrrolidone in the deoxygenated ethanol aqueous solution, stir and mix.

[0064] (2) Add sodium borohydride dropwise to the solution described in (1) under stirring conditions to prepare a nano-zero-valent iron solution and wash.

[0065] (3) Add ethanol solution to disperse nano-zero-valent iron. At the same time, a certain amount of nickel salt ethanol aqueous solution was added and shaken for 30 minutes. Allow Ni to be deposited on the iron surface to prepare nano bimetallic Ni / Fe particles.

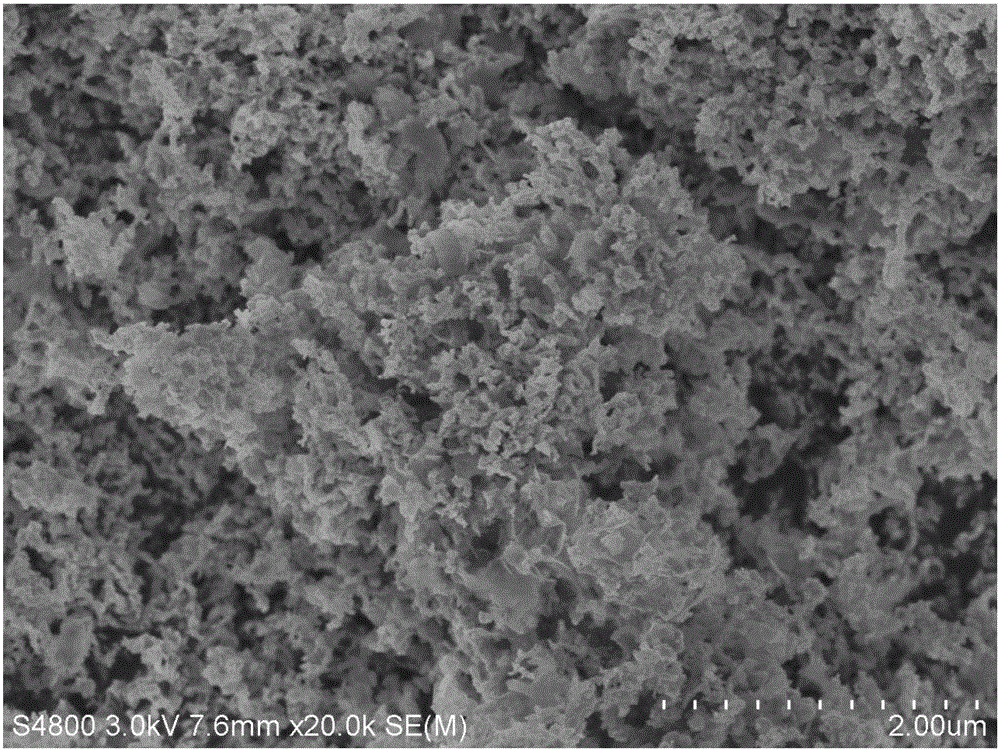

[0066] figure 1 SEM image of the nano bimetallic Ni / Fe prepared in Example 1. figure 1 It can be seen that the single nano nickel-iron bimetallic particles have serious agglomeration.

Embodiment 2

[0067] Example 2 Preparation method of biochar

[0068] (1) Drying: After cutting the collected bagasse into small pieces, it is dried at 105°C.

[0069] (2) Pyrolysis: Put the weighed bagasse into a crucible and put it in a muffle furnace. Under nitrogen, set the final temperature to 600℃, and then continue to carbonize after heating up to this temperature range at 20℃ / min 2h. After the muffle furnace is cooled to room temperature, take it out, and after grinding, pass through a 60-120 mesh sieve and keep it sealed.

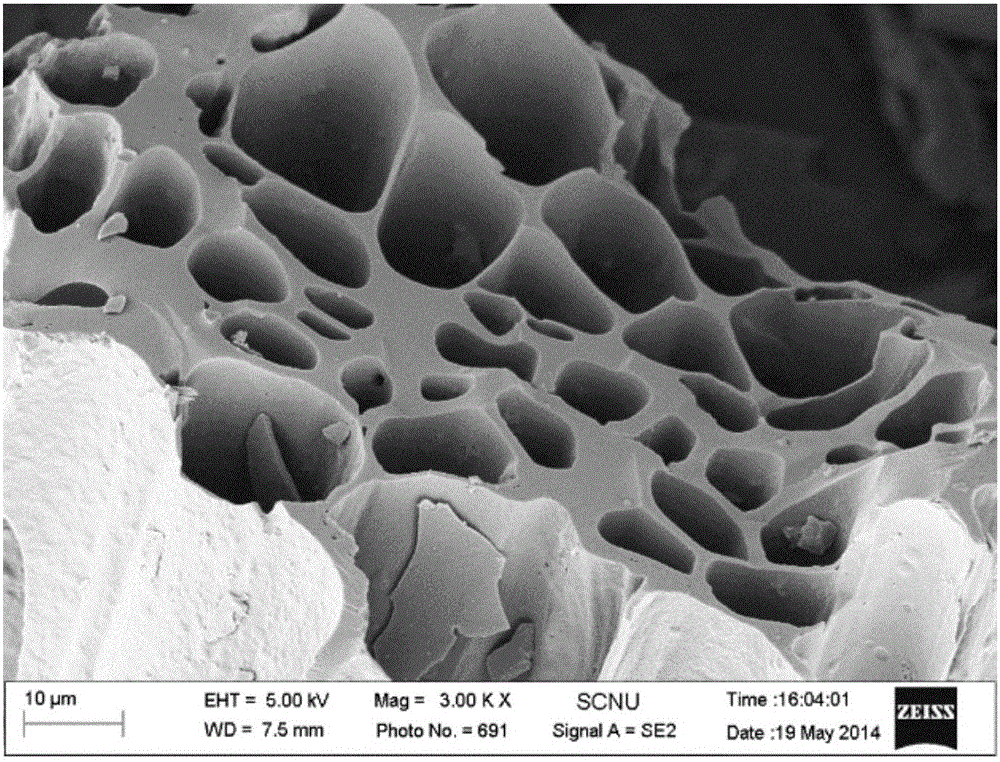

[0070] figure 2 SEM image of the biochar prepared in Example 2. by figure 2 It can be seen that the biochar prepared in this example has a rich pore structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com