Kieselguhr loading solid superacid type Fenton catalyst preparation method

A technology of diatomite and catalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low catalytic efficiency of catalysts, achieve improved catalytic efficiency, increase catalytic efficiency, and have abundant reserves Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

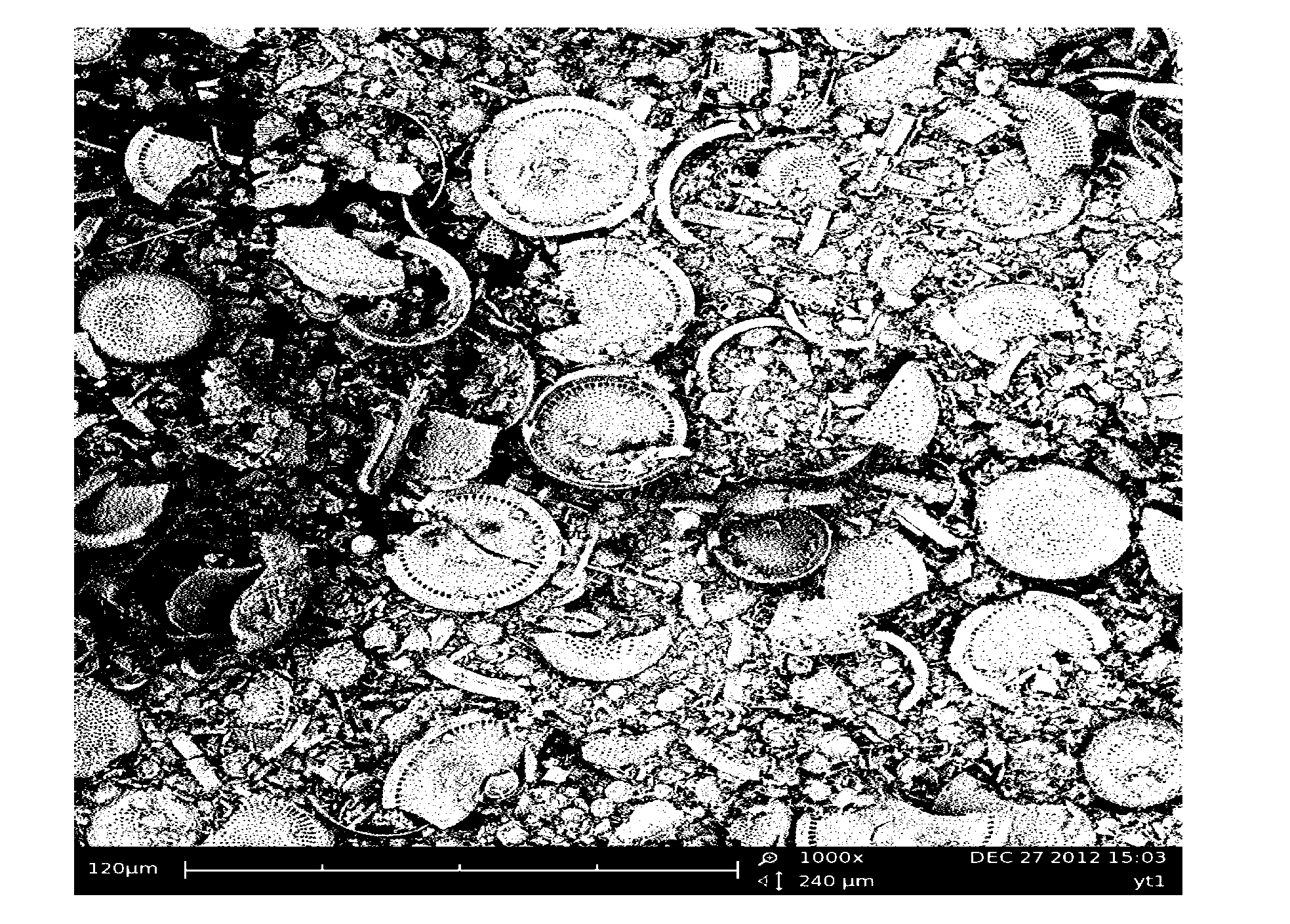

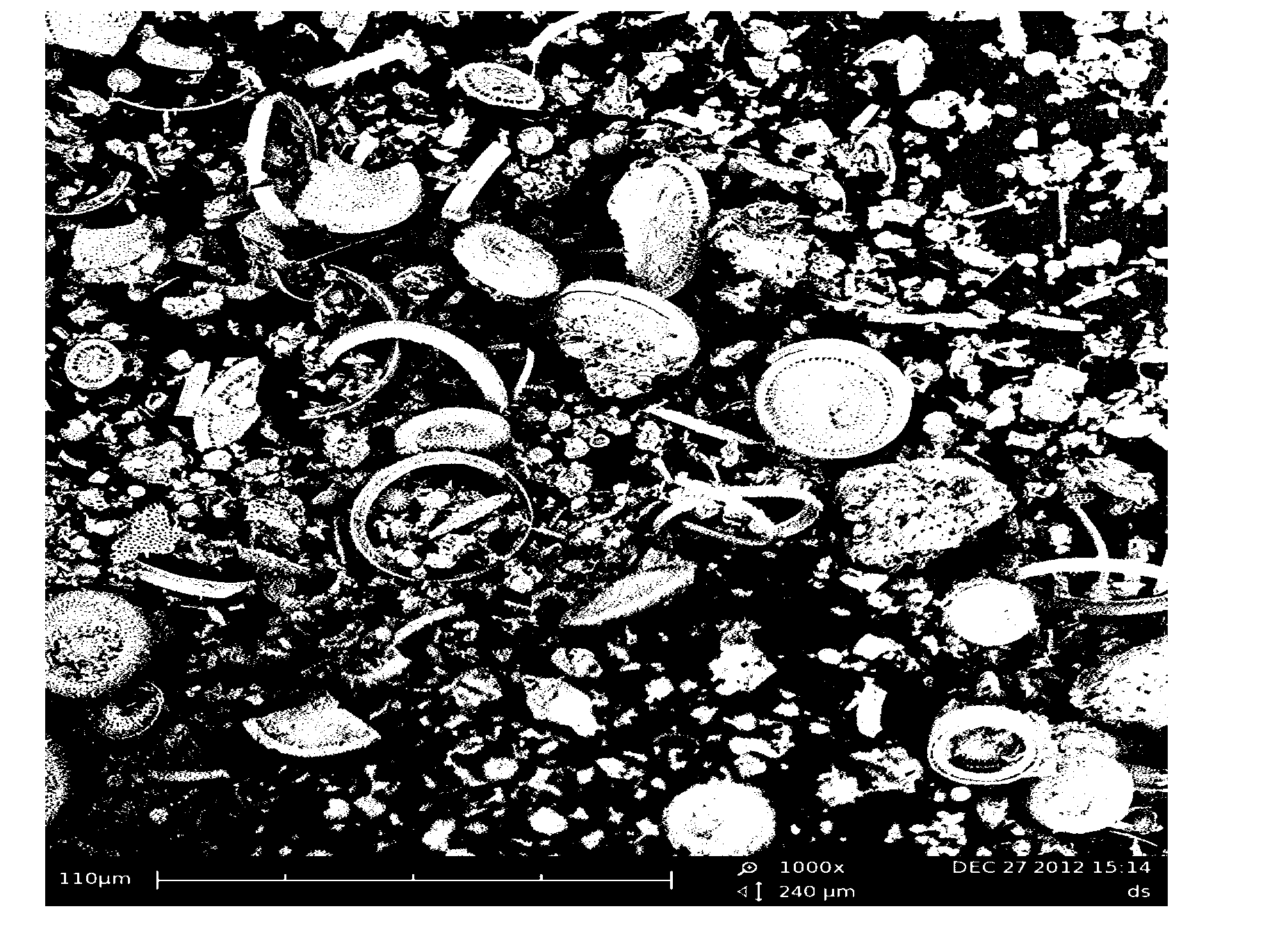

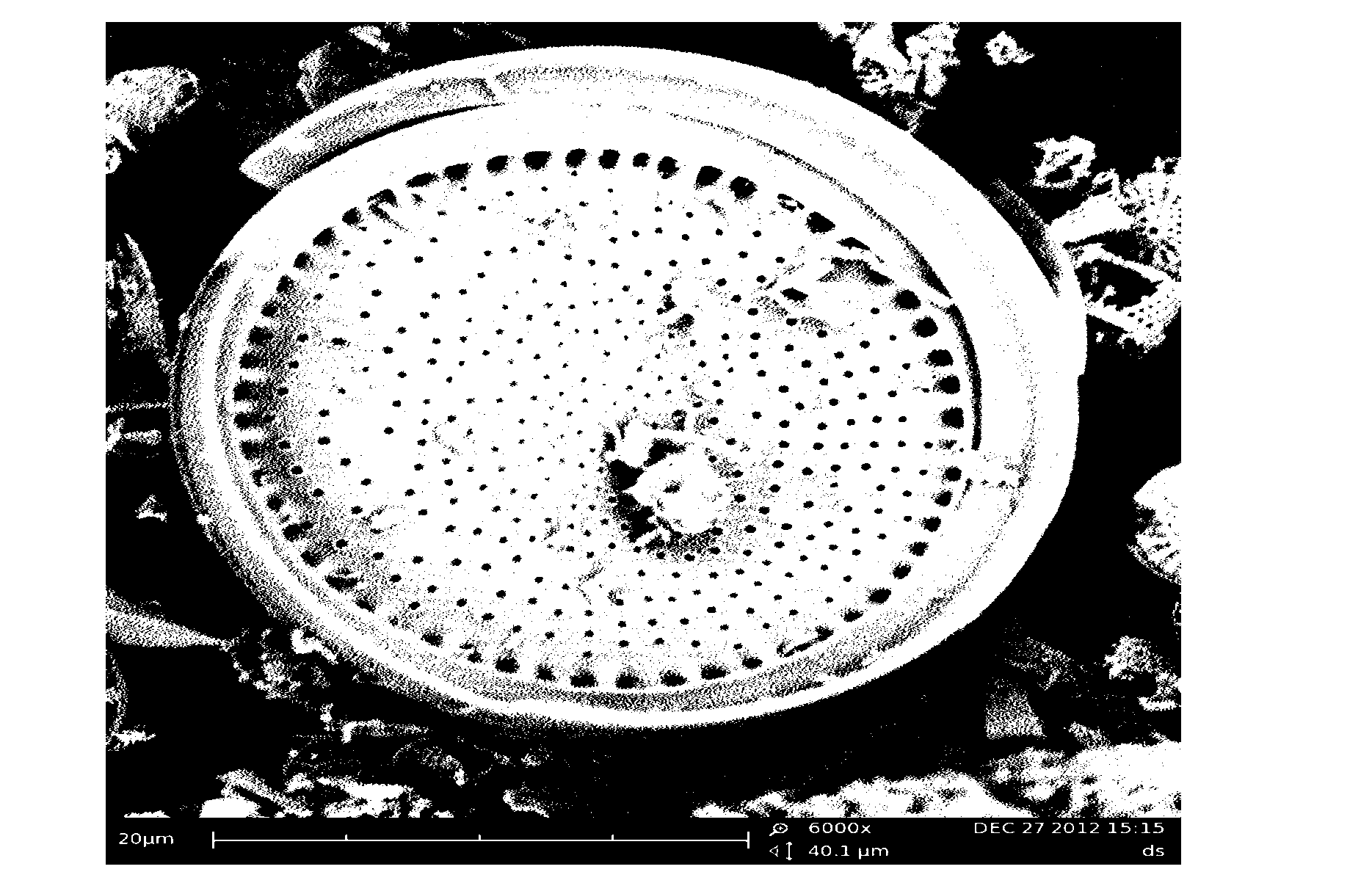

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment one: the preparation method of diatomite-loaded solid superacid Fenton catalyst of the present embodiment is realized according to the following steps:

[0025] 1. Diatomaceous earth pretreatment: immerse the diatomite raw soil in the inorganic acid solution for 10-14 hours, dry it after filtering, sieve after drying, and then put it into a muffle furnace, at a temperature of 200-400 ° C Activation at high temperature for 1 to 4 hours to obtain activated diatomaceous earth;

[0026] 2. Preparation of precursor: Dissolve iron salt in deionized water, then add the activated diatomite obtained in step 1, add lye dropwise to adjust the pH to 7-9, age at room temperature for 6-24 hours and then filter Collect the solid precipitate, wash the solid precipitate with deionized water, dry it, add it to the impregnation solution, soak it for 12-24 hours, filter and dry it to obtain the precursor;

[0027] 3. High-temperature calcination of the precursor: put t...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of the inorganic acid solution is 0.1-1 mol / L. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0032] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that step 1 is dried and then sieved, wherein the mesh number of the sieve is 100-800 mesh. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com