Novel efficient resource utilization method of electroplating sludge and carbon dioxide co-processing

A technology of electroplating sludge and carbon dioxide, applied in chemical instruments and methods, separation methods, metallurgical wastewater treatment, etc., to achieve stable performance, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Use electroplating sludge rich in Fe, Ni, and Cu heavy metals as raw materials, bake at 105°C for 2 hours, pyrolyze at 900°C for 4 hours under nitrogen gas atmosphere, stir in 2mol / L HCl solution for 24 hours after cooling, wash with water until neutral, 105°C Dry and grind to 100-150 mesh, which is sludge biochar.

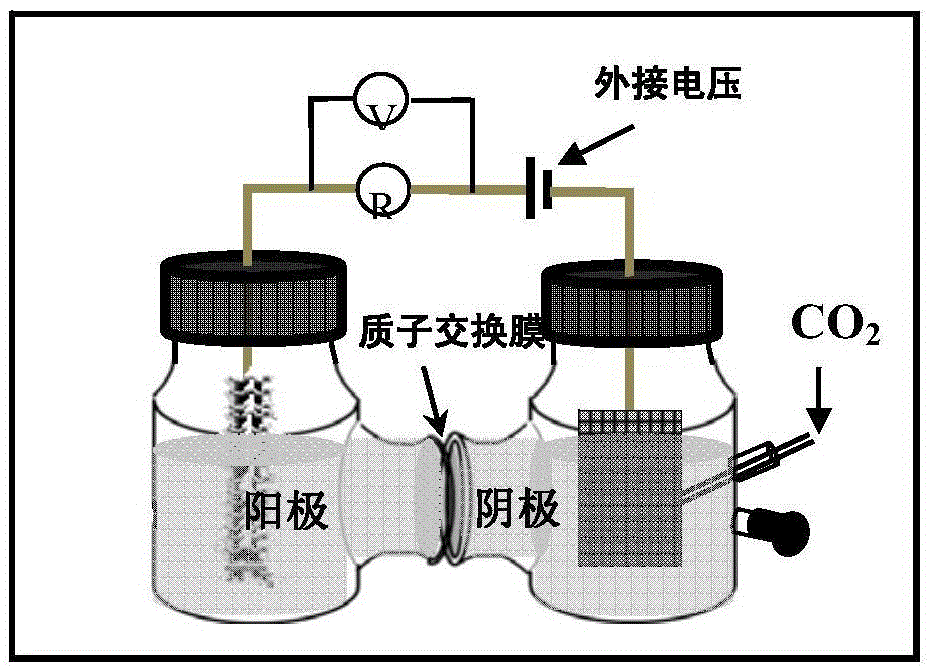

[0030] Mix the prepared sludge biochar (20mg) or the electroplating sludge (20mg) before pyrolysis with 1ml of ethanol and 1μl of nafion solution, ultrasonically form a paste mixture, and mix the paste mixture at 0.5-1mg / cm 2 The loading of the carbon cloth is loaded on the carbon cloth, and the carbon cloth loaded with the paste mixture is used as figure 1 In the cathode catalyst of the bioelectrochemical system shown, carbon dioxide is introduced into the cathode chamber of the bioelectrochemical system to realize the synergistic treatment of electroplating sludge and carbon dioxide.

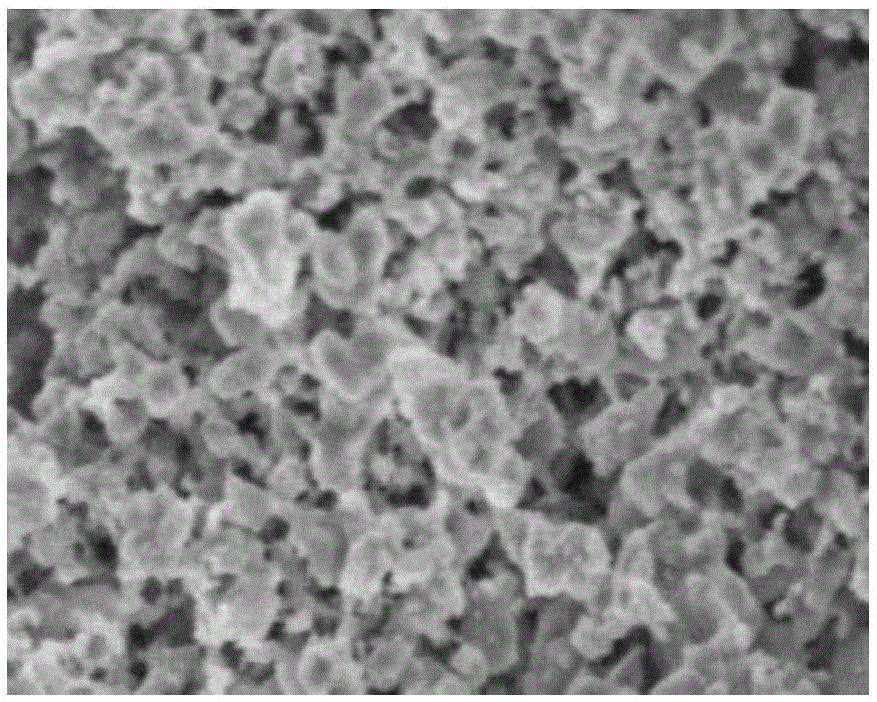

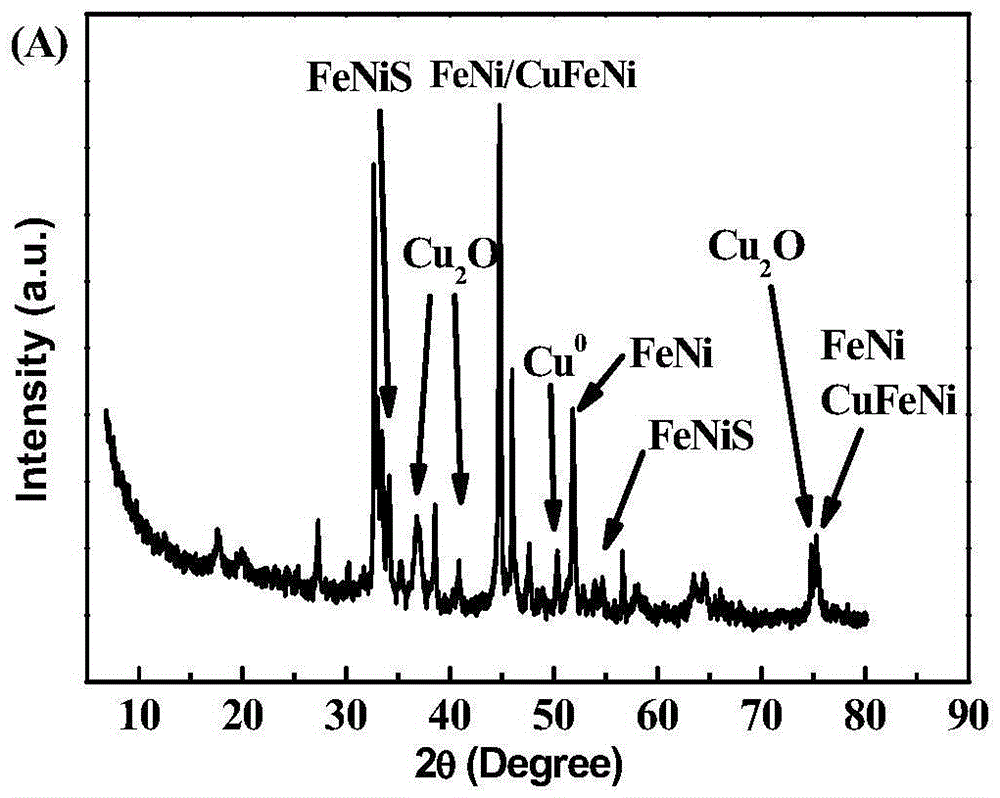

[0031] The physical and chemical characterization of the prepared slu...

Embodiment 2

[0034] Same as Example 1, the difference is:

[0035] Pyrolysis at 700°C for 2h under nitrogen gas atmosphere.

[0036] Because 4 hours pyrolysis time makes pyrolysis reaction more thorough in embodiment 1, therefore, its pyrolysis prepares CuFeNi, FeNi, Fe 1.6 Ni 2.4 , Fe 8.7 NeS 10 and Cu 2 The effect of metal compounds such as O is better than that of pyrolysis for 2 hours in Example 2.

Embodiment 3

[0038] Same as Example 1, the difference is:

[0039] Adjusting the applied voltage is 0.6V, and monitoring its cathode product finds that a small amount of formic acid, acetic acid and methane are produced, and the acetic acid output is as follows: Figure 5 and formic acid production as Figure 6As shown, the concentrations of formic acid, acetic acid and methane were significantly higher than when the applied voltage was 0.3V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com